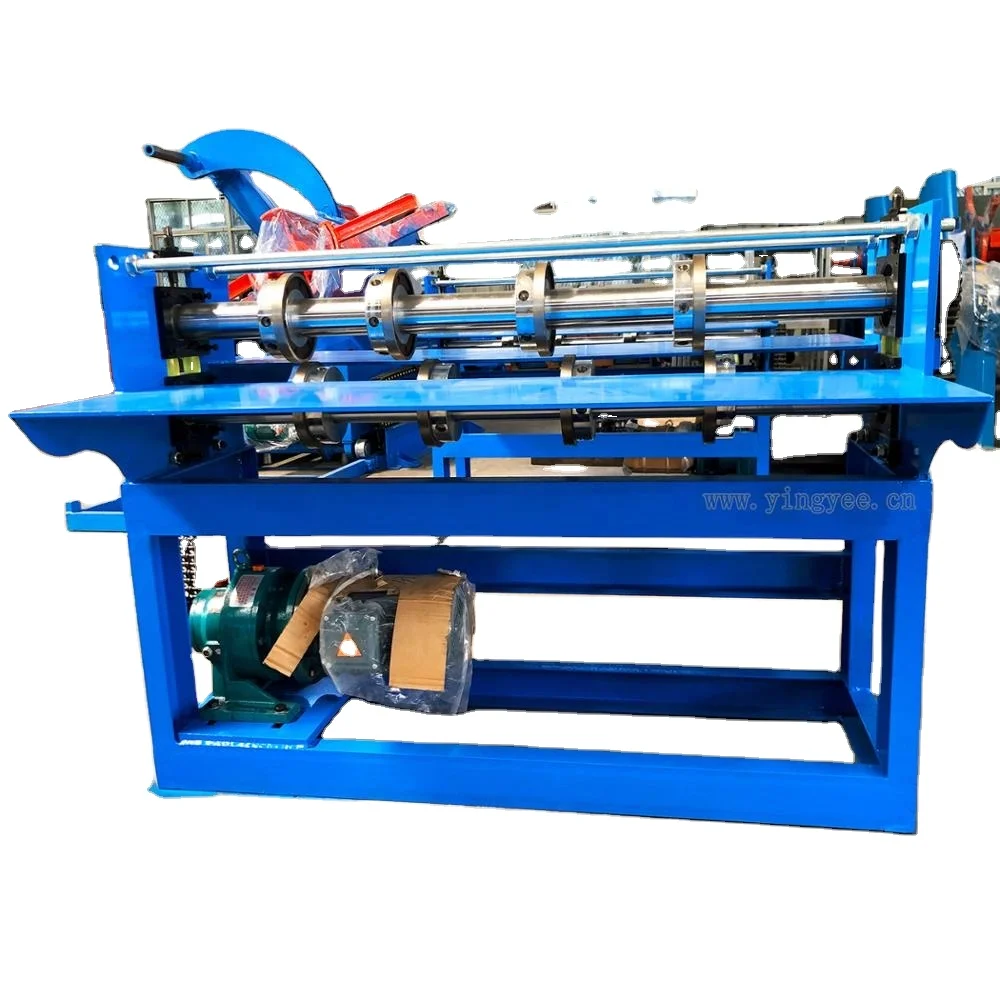

Cable trays also are very important items that are used throughout factories and buildings. They assist in the organization and holding of electrical wires. This organizational aspect is important because it helps protect the cables from being damaged and makes it a lot easier to add or change cables if needed later on. With people and companies always needing cable trays, there are now much faster more efficient ways of producing the trays while maintaining the quality that the trays need. More efficient and automatic machines have been made especially to speed up the production process such as the new machines like YINGYEE.

Cable tray machines may have a wide variety of models, and how they work can vary, however, understanding the basic workings of a cable tray machine is useful for promoting its proper use and handling.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY