Revolutionizing Cable Tray Production with Cutting-Edge Assembly Lines

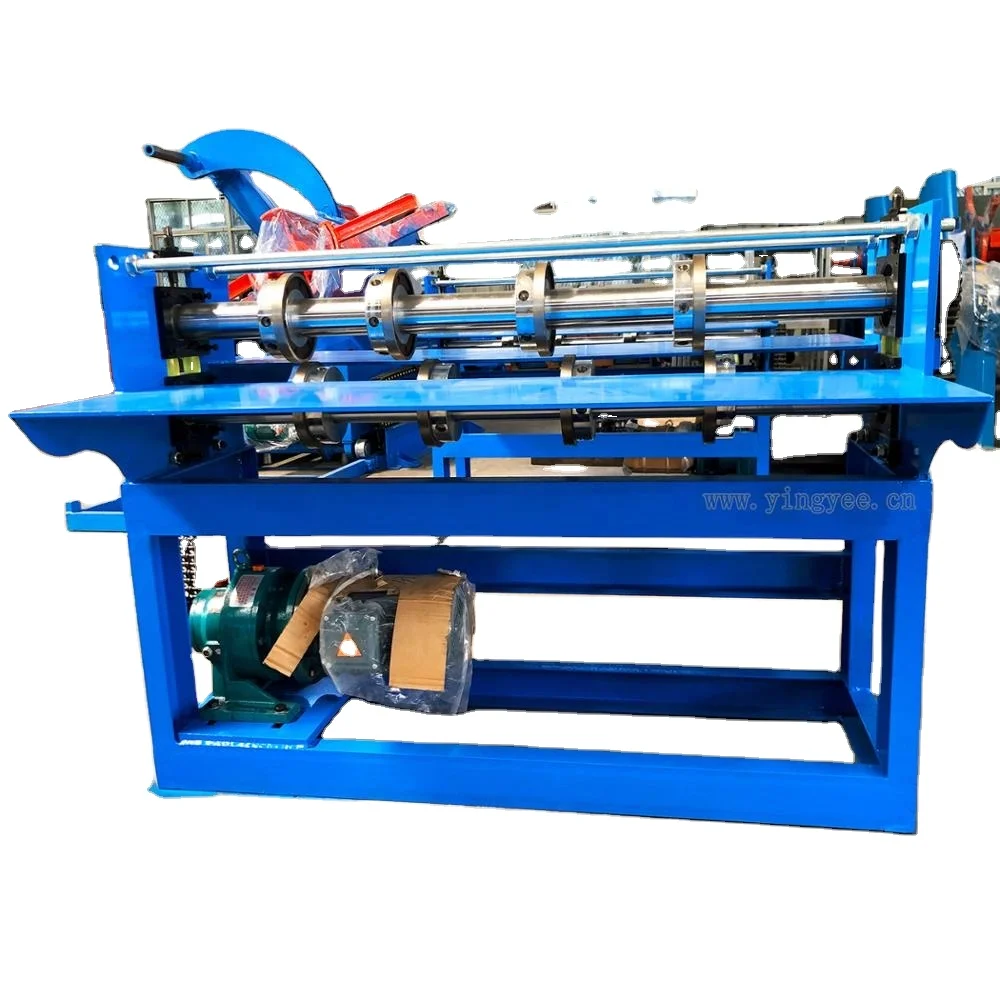

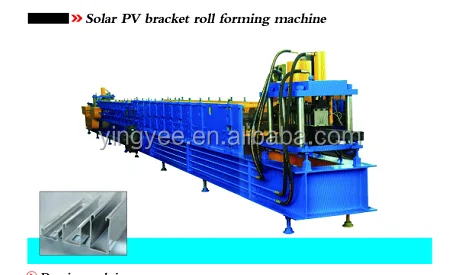

Machines from YINGYEE have really transformed the manufacture of the cable trays. Using their tech from now and the future, they have developed the whole process of production to become better, simpler and easier. This allows the companies to manufacture cable trays which are of premium quality without high funds. These advanced machines allow businesses to meet the constant demand of these cable trays as they are placed at various locations such as schools, offices, and factories.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY