A bright future for sheet metal processing

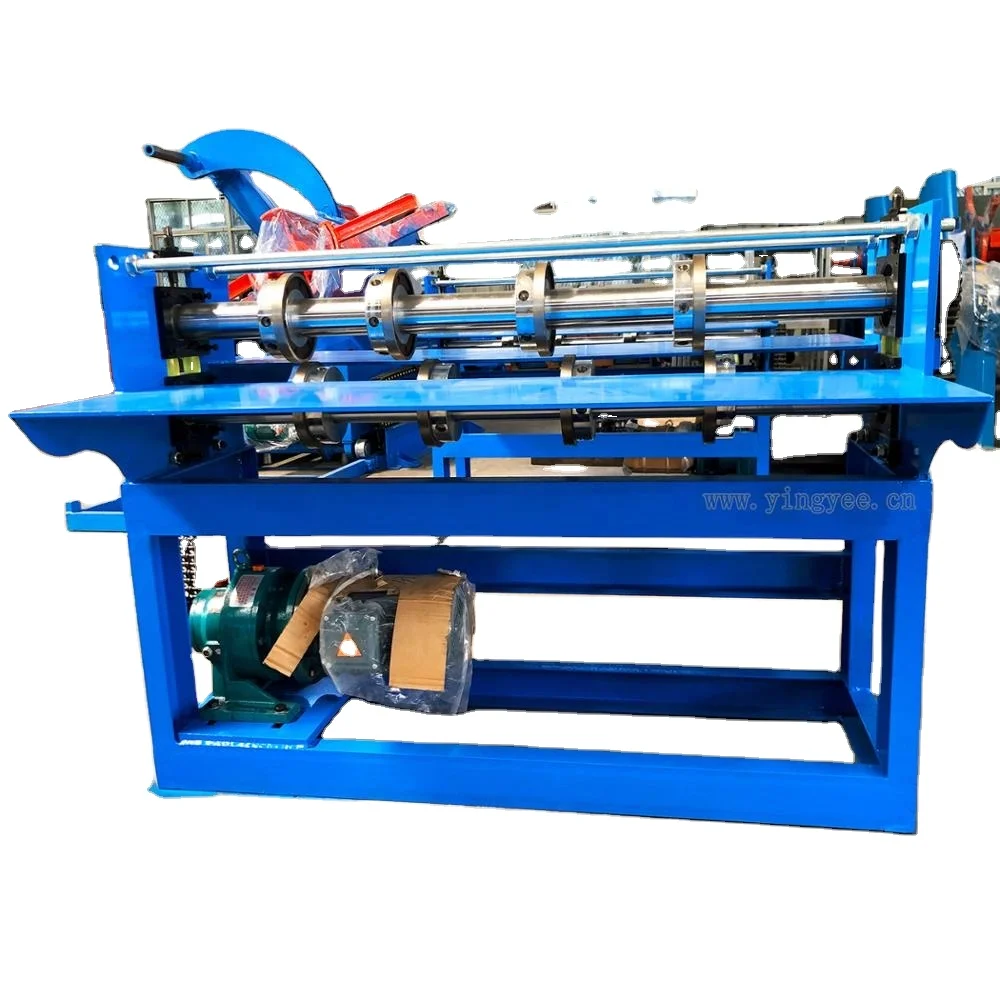

By now, the introduction of computers and automation in roll forming is no surprise; they are just making cold roll forming even better with the use of storage rack roll forming machine. Now, the operators are programmed for all specific parts that they need and then machine automatically can start working. It not only saves time. In a renaissance fair the equivalent of death on stage, and in large productions like these mistakes translate to big issues. Keeping error small can keep costs down which as one may know are high enough already for production.

In this day and age, it is also crucial to discuss how a manufacturer can become more environmentally conscious while creating metal products. Companies are thinking about how they can cut waste and energy usage from their processes. Flexospan is a specialist in roll forming heavy gauge steel and other types of metal, as it has for decades been an alternative to hot forming. New machines have even came out that can recycle any extra bits of colored sheetmetal after you cut what you need from the formed bit during manufacturing. This equals the use of less material as well as more environmentally friendly manufacturing methods for metal products.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY