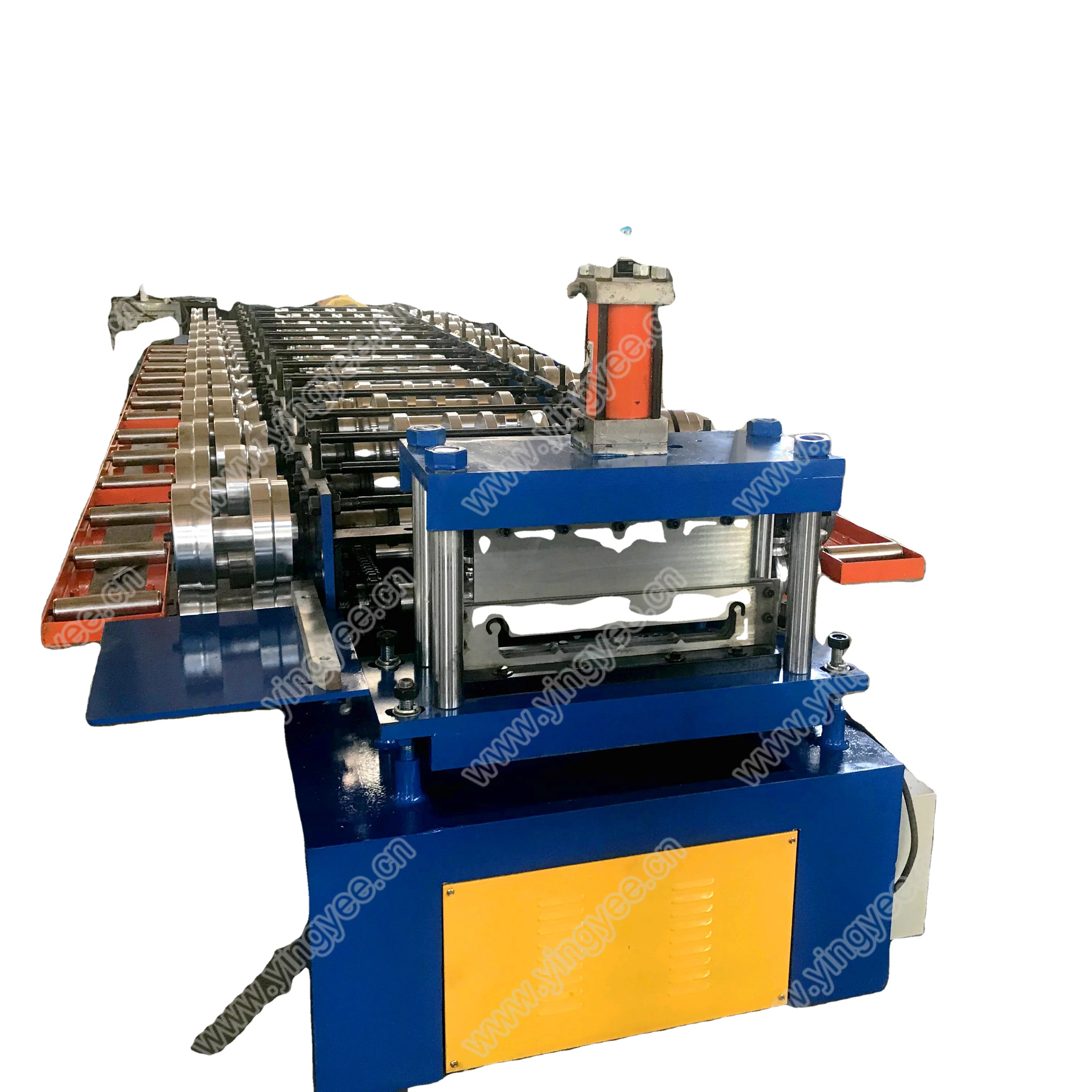

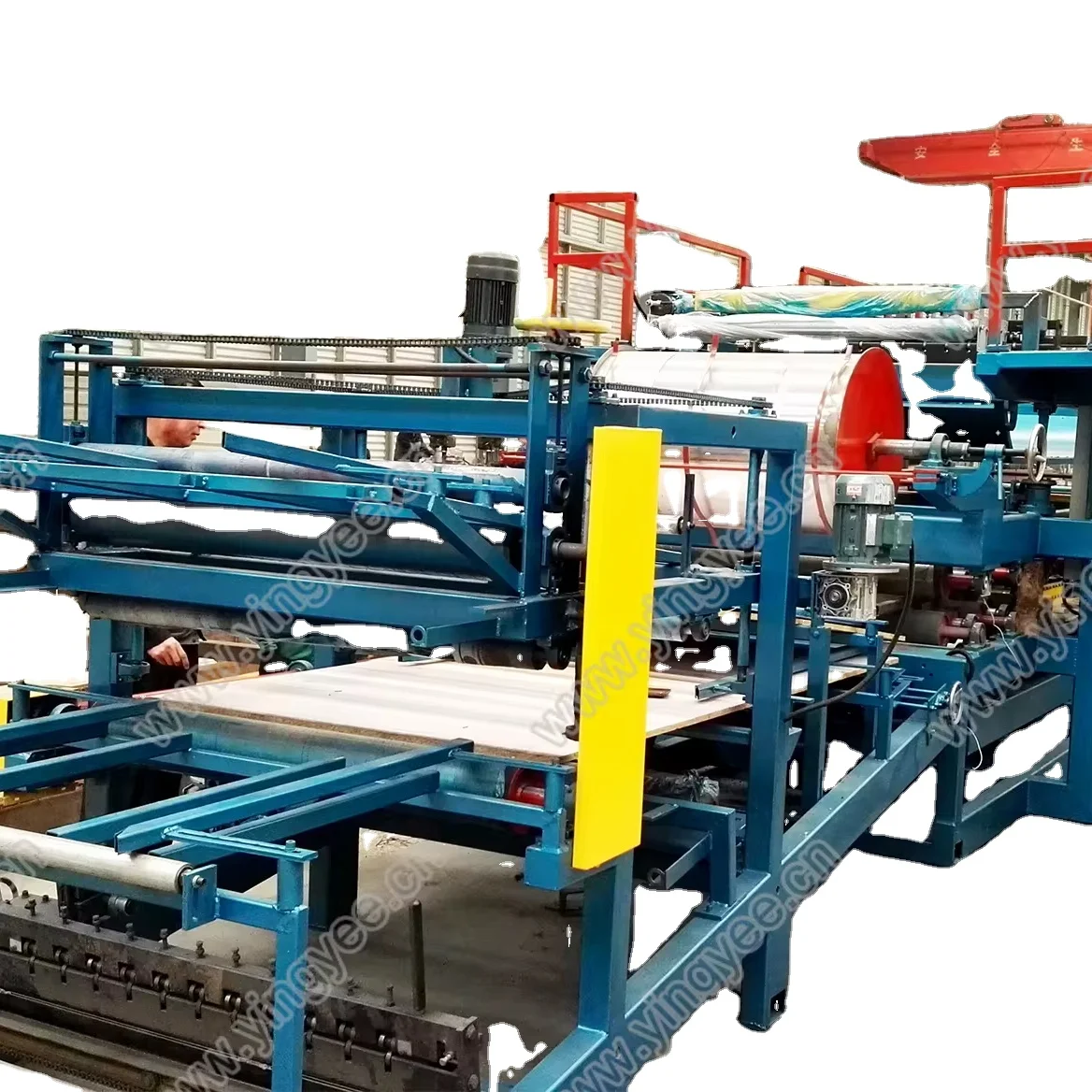

The Capabilities of Forming Machines

Indeed, metal roll forming machine have transformed how many jobs are done today in business. It was a time-consuming, labor-intensive process to make parts out of metal. Creating these parts before was more difficult and required more time, but now with forming machines we are able to produce this more conveniently and faster. With the high efficiency they operate, companies can manufacture a higher number of products in a shorter time span. This enables businesses to fulfil customer demands more effectively and spend less on producing their offerings. Many organizations have benefited from the speed and efficiency with which forming devices help them to grow and thrive.

Forming machines have come on ln leaps and bounds over the years. The machines have developed — so too has the way the technology in them is designed. Machines today are also much stronger, as well as far more accurate, so they can produce parts the exact appropriate size and shape. This ensures that everything is the proper fit. Modern forming machines also use less electricity compared to older machines, which is yet another benefit of modern forming machines. This is more eco-friendly because it saves energy as well as produces a large number of parts.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY