Highway guardrails are critical components of our roads and highways. They protect drivers and passengers from things that may be on the road shoulder. These guardrails are meant to reduce the severity of crashes, prevent cars from leaving the road, and stop them from hitting deadly objects. Creating these guardrails requires special skills, careful planning and sophisticated machinery.

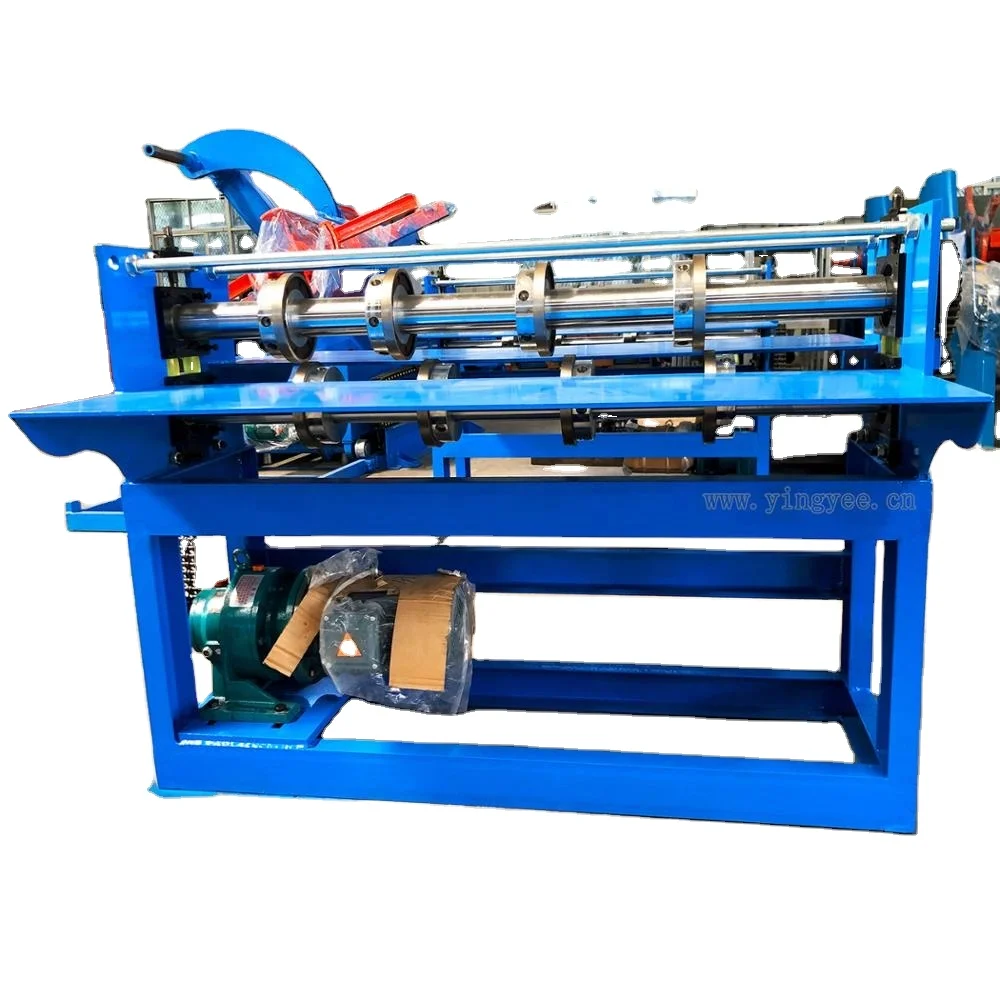

YINGYEE knows that nothing is more important than the production of high-quality highway guardrails. And that’s why we have created machines to help us build these guardrails in a more timely manner and higher quality than we ever have before.” Our portable guardrail making machine designed specifically to made the strong and highend type of guardrails in varieties of designs and sizes. I think it simplifies our job to serve the needs of varied roads and highways,” he explained.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY