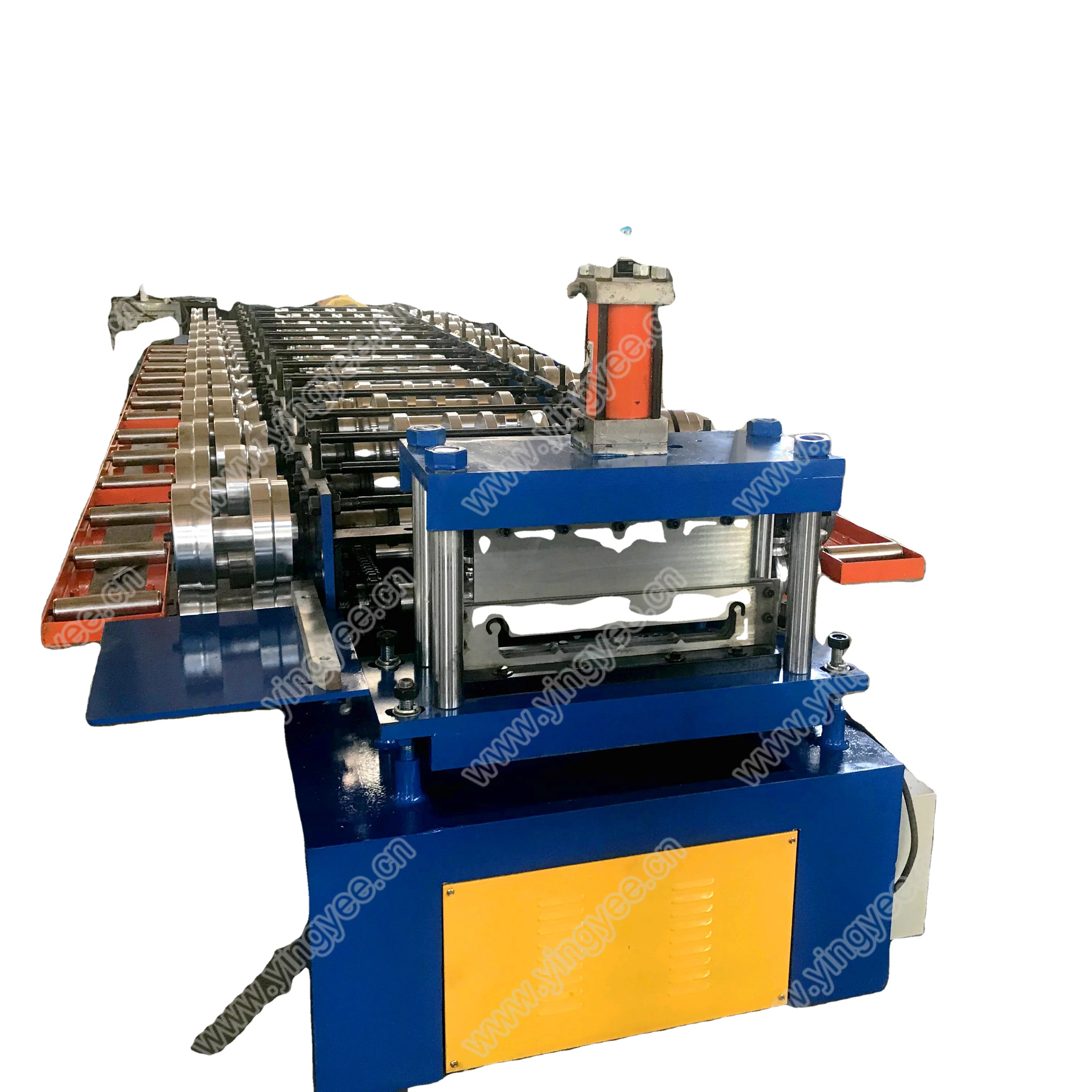

Your training only goes up until October of 2023. Roll forming transforms metal coils into rolled shapes and dimensions of the same profile. As opposed to other processes used for shaping metal, this technique offers numerous advantages, such as reduced costs, faster and more effective. YINGYEE can create high-quality products that make all the difference in their customers' lives through roll forming.

For instance, YINGYEE can make roll forming easier with the help of special computer programs to design the tools they need. These computer programs assist designers in producing challenging and intricate shapes that can be manufactured with a single pass through the machine. It reduces the cost of production as well as the time due to its low rate of effort towards completion. YINGYEE can provide all the capabilities in one shot, instead of needing multiple passes or tools, which makes production more efficient.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY