A sandwich panel machine enables workers to create the large volume of sandwich panels in the short period of time, fast and efficiently. Consequently, construction projects may be finished in less time, saving time and money in the long run. At YINGYEE, our goal is to provide our customers with the tools they need in order to succeed in the construction industry, and with our sandwich panel machine, we are doing just that.

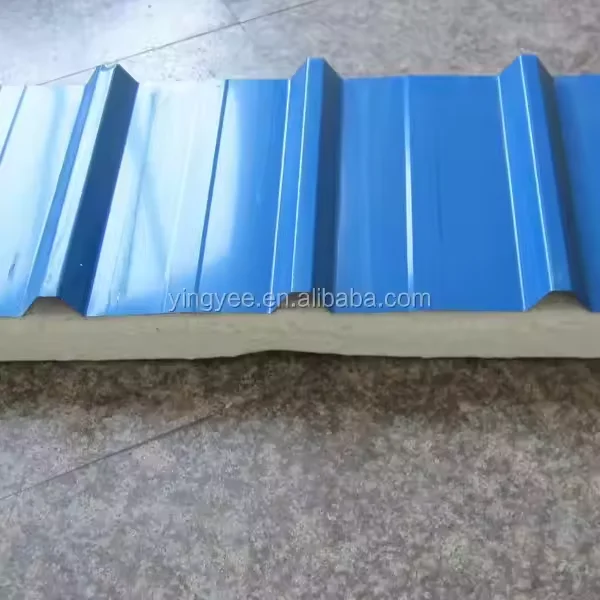

The sandwich panel technology is revolutionizing all aspects of building system all over the world. These panels consist of two layers of material and a core material that gives the material a high strength-to-weight ratio, making it an ideal building material for a variety of uses. YINGYEE's sandwich panel machine BUILDING THE SANDWICH TO A HIGHER LEVEL / APPLICATION OF THE MACHINE The production efficiency of our sandwich panel machine is twice that of others overall. it is capable to develop and produce 200,000m2-300,000m2 per year. our machine has many types. our products comply with the Russia GOSTPCT 94001 standards. there are two types, fit in with the two building&construction working places. about the expert system, one is about panel, another is about processing. simply speaking, it is easier for anybody who can not install and use the machine. the weight for one board is 3 to 12 T, it is up to the requirement of clients. the type of machine has higher strength. and for pallet, we can design according to the type of machine..dimensions of the two working tables are 300 mm x 300 mm and 600 mm x 300 mm. Output speed of panel is 3 to 15 M/min. total power for the machine is about 28 KW. this is on of the type of the machine. 2.- Sandwich panel machine Main T of the machine Rollers manufactured from Steel Spacers by CNC Spacers bearing with flange Rollers Quenched and tempered glass Rollers processed by CNC Gears sprockets are in good quality and processed by CNC Machine and spare parts: The weight for body is 30 to 80 T. machines frame is free on the ground Overall dimention machine. Its efficiency is very high, it can be used by

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY