Exploring the Features of a Sandwich Panel Roll Forming Machine

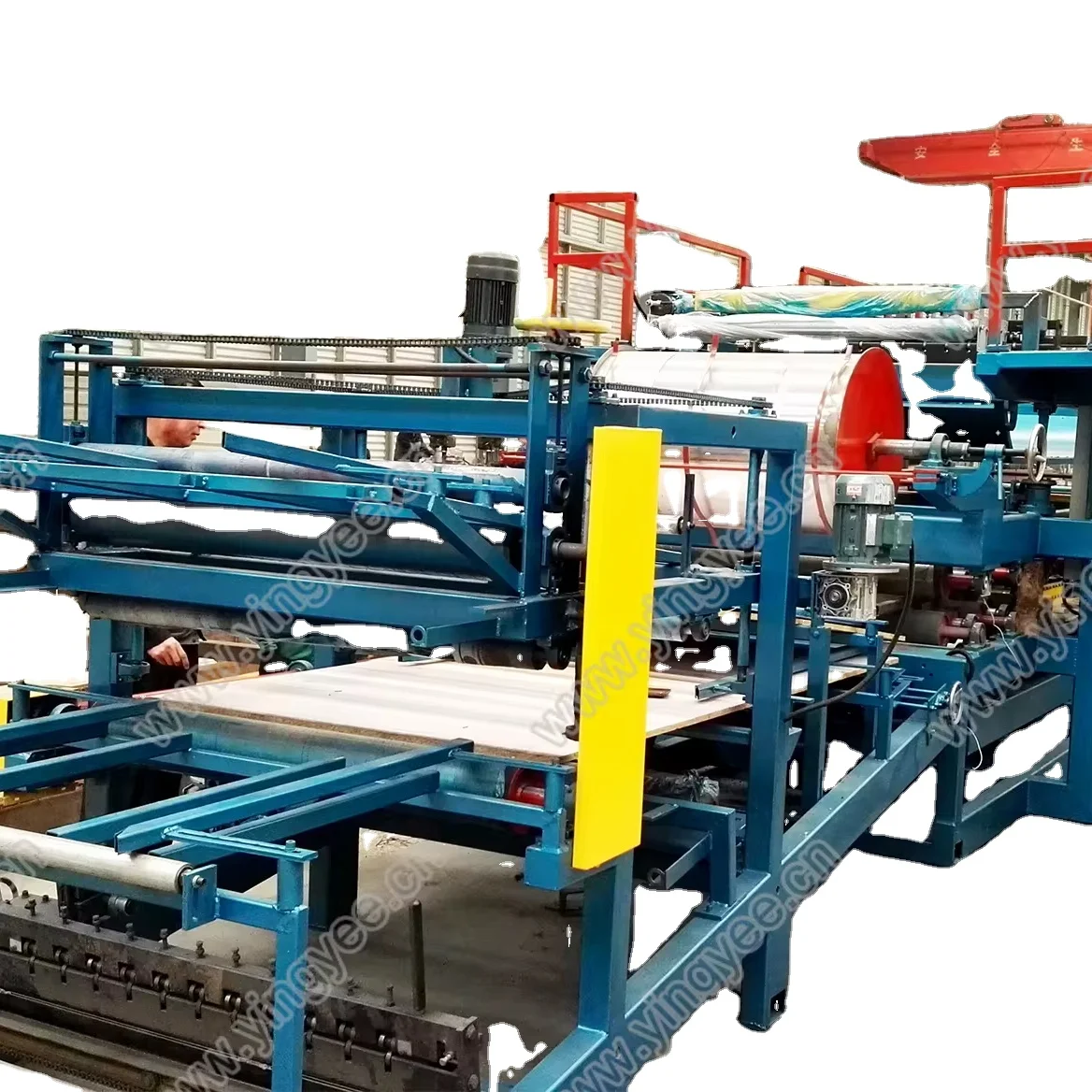

Yet another reason to get a Sandwich Panel Roll Forming Machine is that it is highly effective. This provides enables you to produce many panels in a short period of time, so you can save time and money on your projects. YINGYEE's machine is easy to operate, which can be made the newcomer can also like easily master; it also make the expert use.

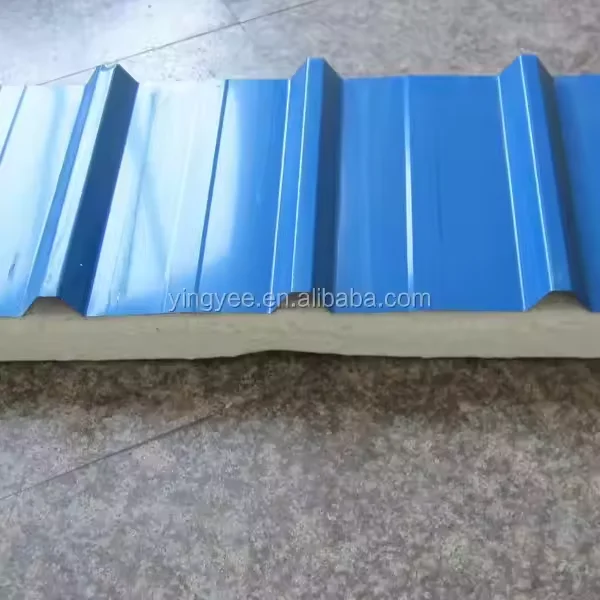

YINGYEE's Sandwich Panel Roll Forming Machine has multiple components which contribute to the success of these machines which include are speed controllers, high quality cutting tool, and machinr controls. As such, it’s simple to fabricate panels of any size or shape, ensuring that you can easily tackle any job that comes your way.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY