Are you familiar with sheet metal? It‟s a very thin and flat metal. Sheet metal is used to make all sorts of things, from cars to airplanes and even phones! Before we can use this sheet metal in factories to produce the final products, it has to be straightened out, and hence, it is a process that can be used on metals such as aluminum, steel, copper, etc. The reason for this is the metal that isbent or that is not flat will never deficiency to make things from.

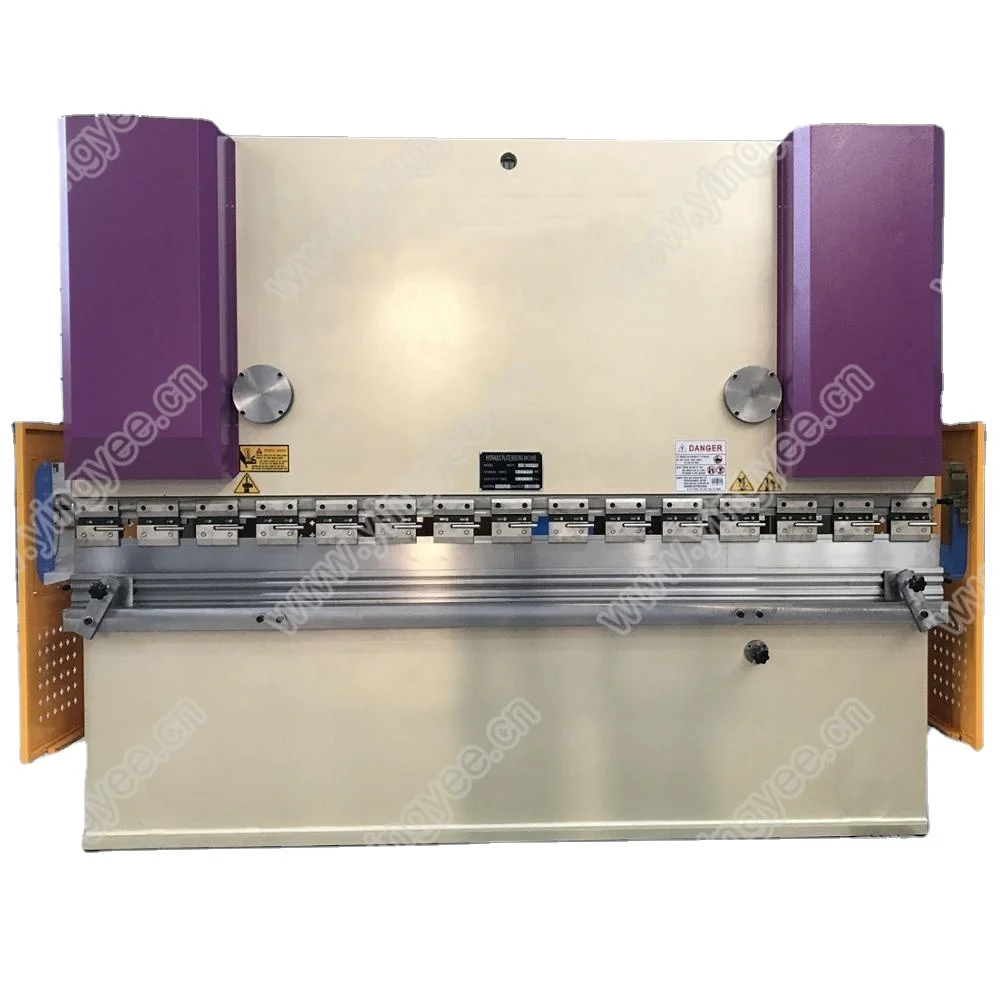

For the straightening process, YINGYEE invented a special machine, previously workers had to straighten the sheet metal by hand. They would hit the metal, beating it into a straight line with hammers and other implements. It was a long and exhausting process. Workers needed to be careful and powerful to keep the metal straight. But now with the assistance of YINGYEE'S machine, it is much easier and faster to straighten the metallic sheet!

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY