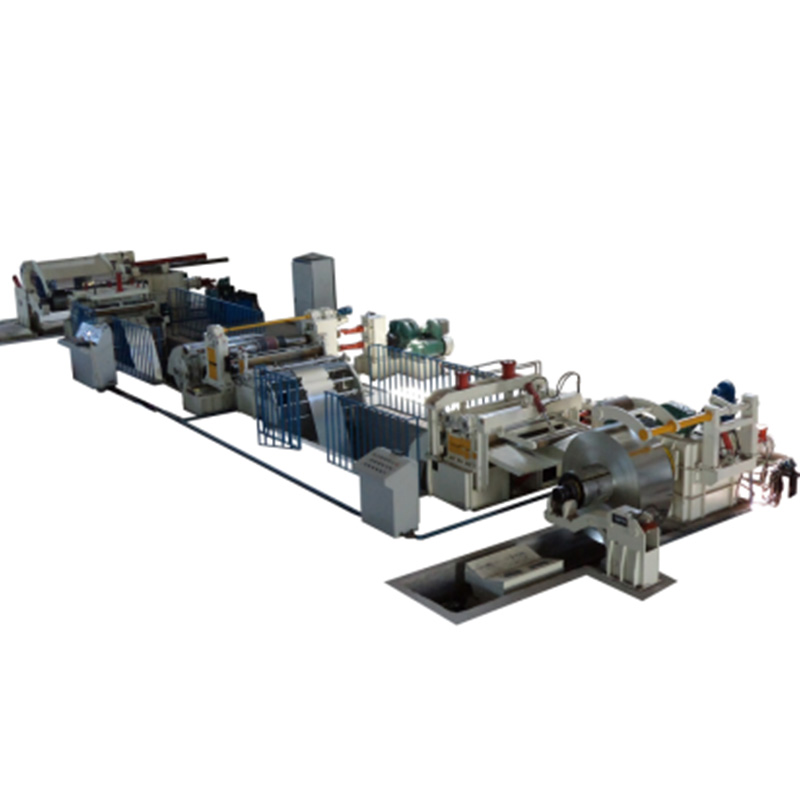

Stud and track machines are big horrible beasts that craft metalsons of strength. Precision machines are essential because they make very exact steel parts that go into all kinds of things - from buildings to automobiles, and everything in between.

Stud and track roll forming machines are known to produce consistent steel components. They operate by feeding a long metal strip through many sets of rollers. Every roller shapes the metal in a completely new way. As the metal slithers between every one of these rollers, it changes step by step. It emerges from the machine as a finished steel part with an exact shape.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY