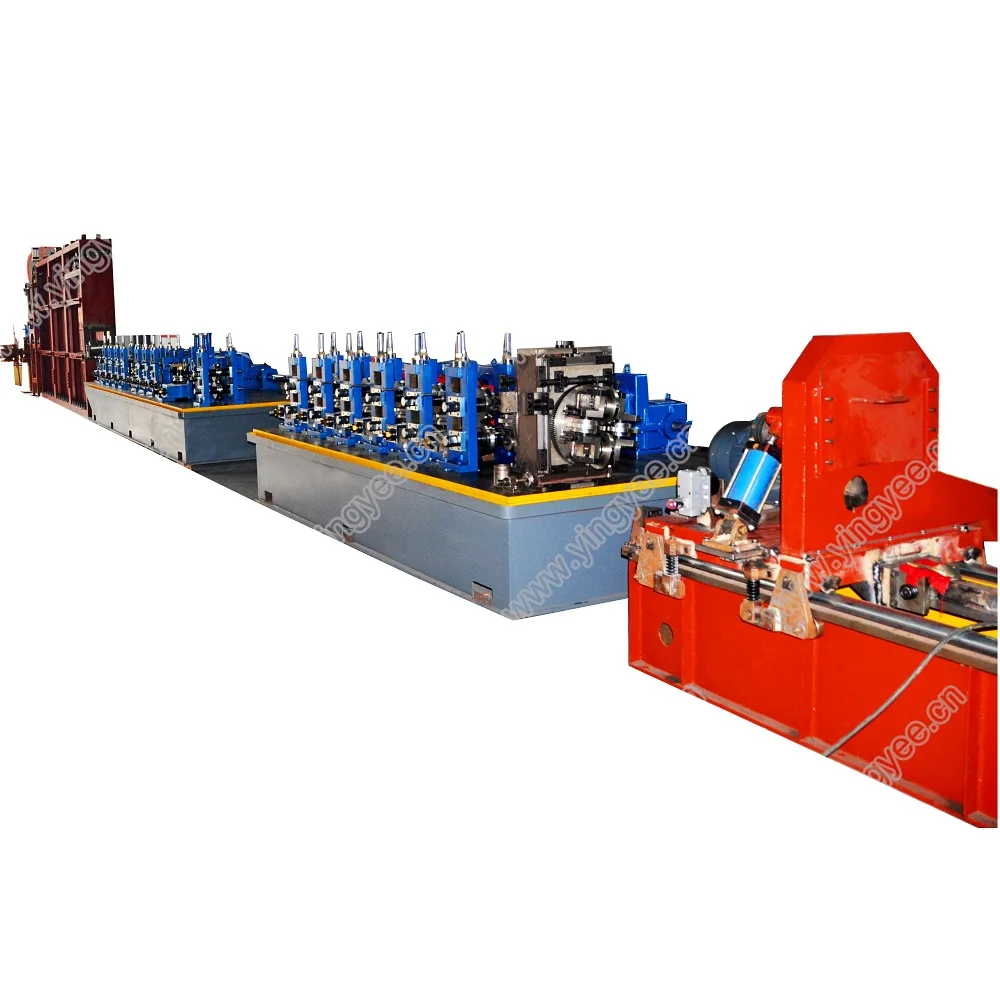

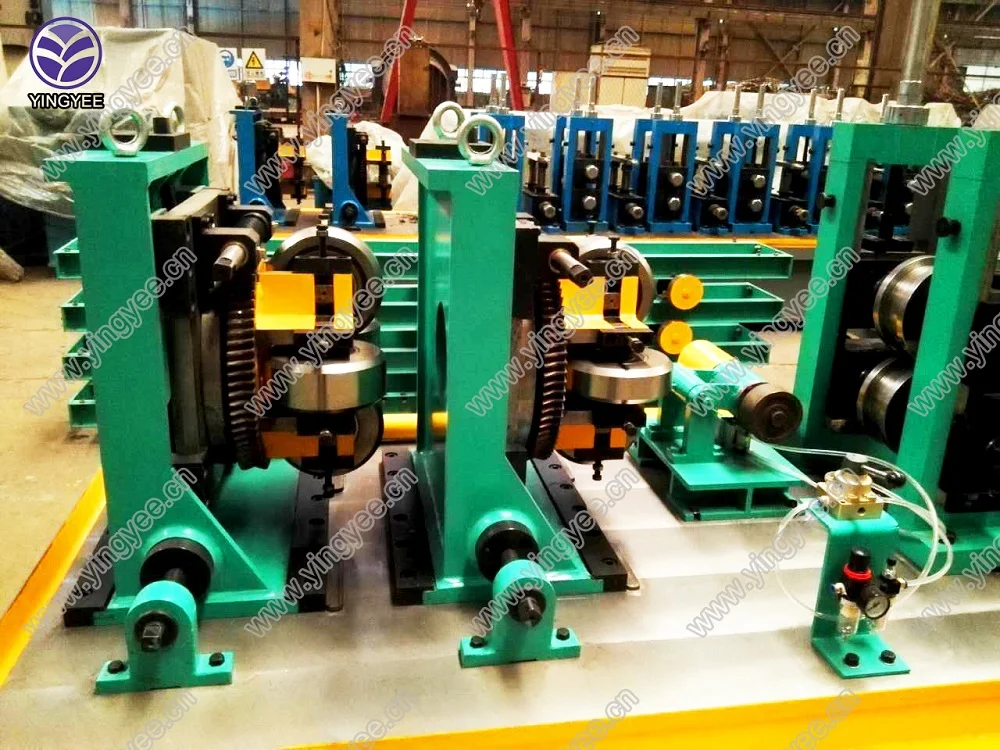

Tube mill rolls is the most significant part of making metal tubes. They “ensure the tubes are the right shape and size.” YINGYEE produces good Tube mill rolls, which help the factories produce tons of tubes quickly and in very good precision.

The function of tube mill rolls is not a mere that of forming a rim around the edge of the tube. They are like special hammers to shape the metal to be round tubes. Without these rolls, it would be really difficult to make tubes in the right way. YINGYEE tube mill rolls are made to be strong and long lasting, used to make tubes round. They can be re-used to making tube one by one.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY