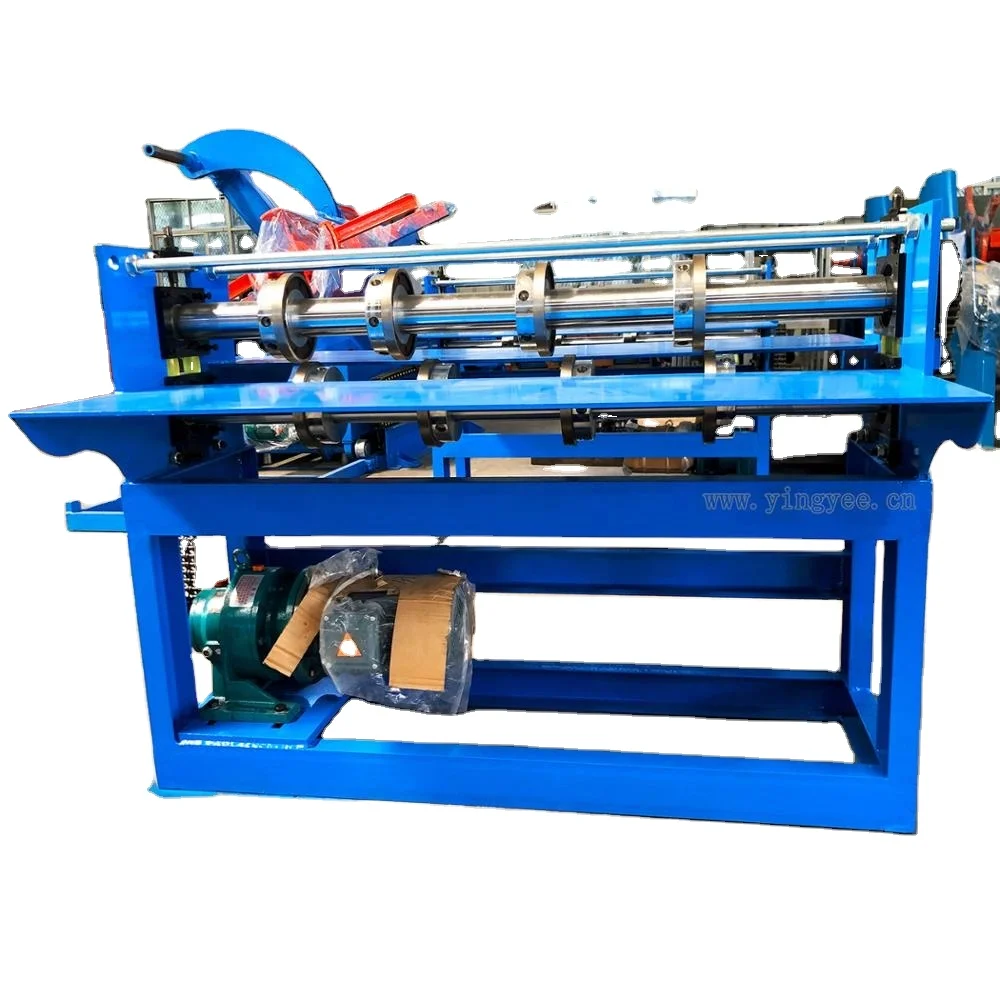

Autrefois, il y a très longtemps, existait un appareil mystique appelé la Machine à former des profils en C par pliage. Cette machine est fabriquée par YINGYEE, et nous sommes un fabricant professionnel d'équipements de pliage à froid. Découvrons-en davantage sur le fonctionnement incroyable de cette machine et pourquoi elle figure parmi les plus utiles de son genre dans divers domaines professionnels.

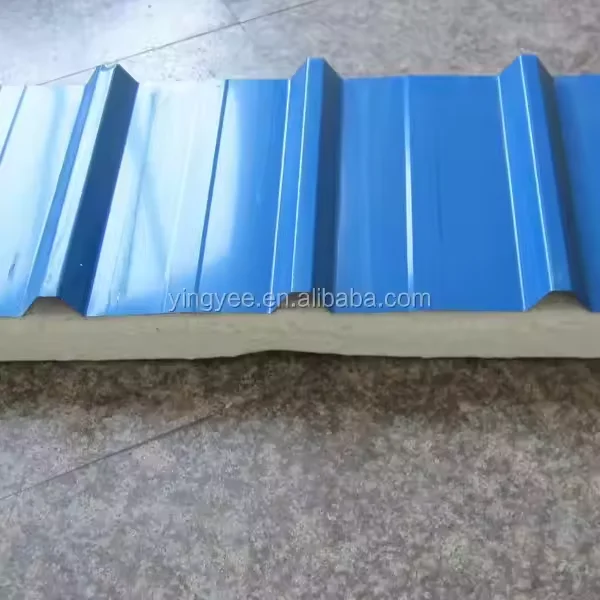

Machine de formage par laminage en C La machine de formage par laminage en C est spécialement conçue pour le laminage des aciers en forme de C. Ces profilés sont largement utilisés dans la construction, l'industrie et d'autres domaines. La machine fonctionne en prenant une bande plate de métal et en la transformant en forme de C. Plusieurs passes sont effectuées pour produire de longs profilés en C qui peuvent être utilisés pour diverses applications.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY