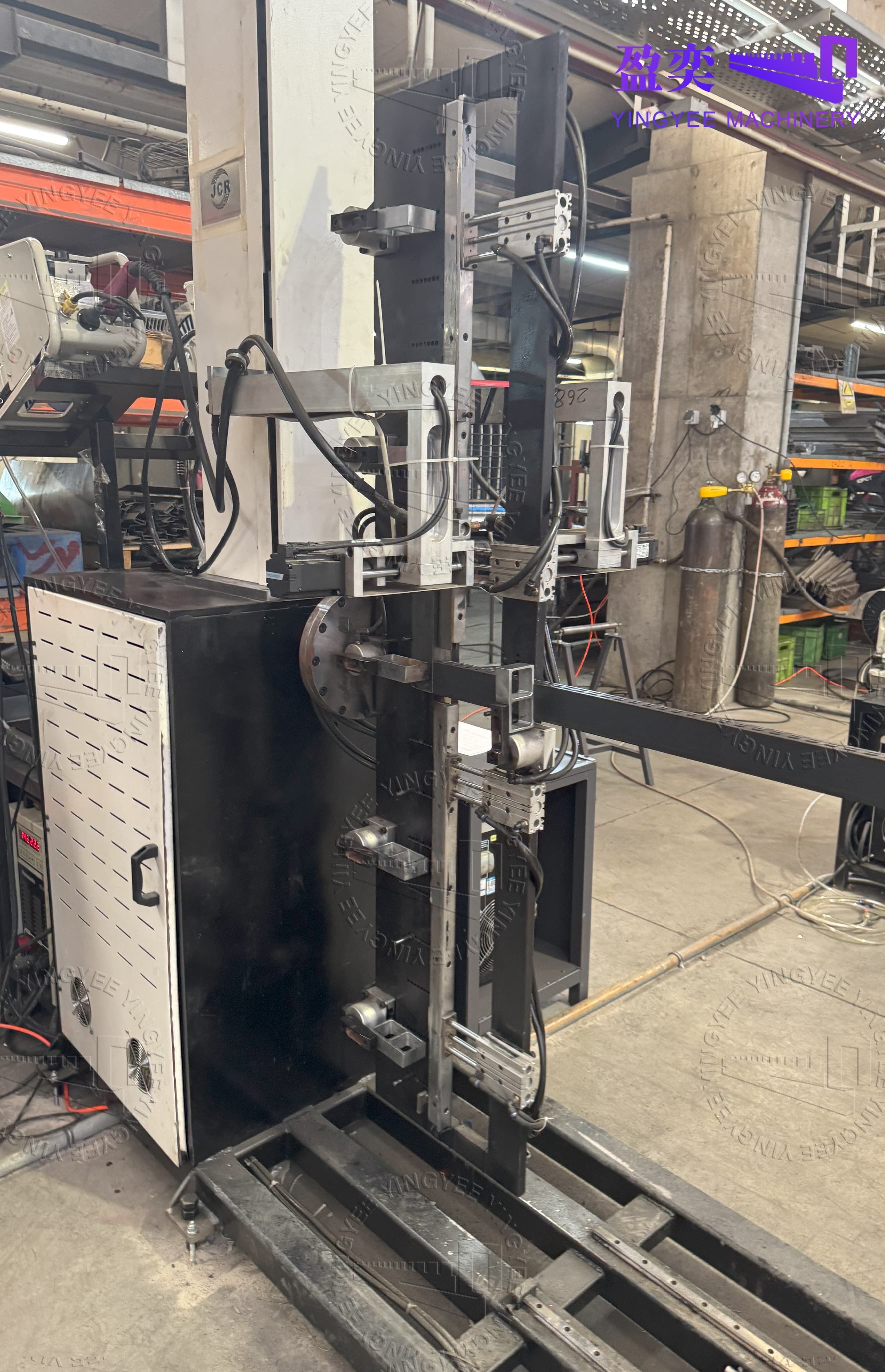

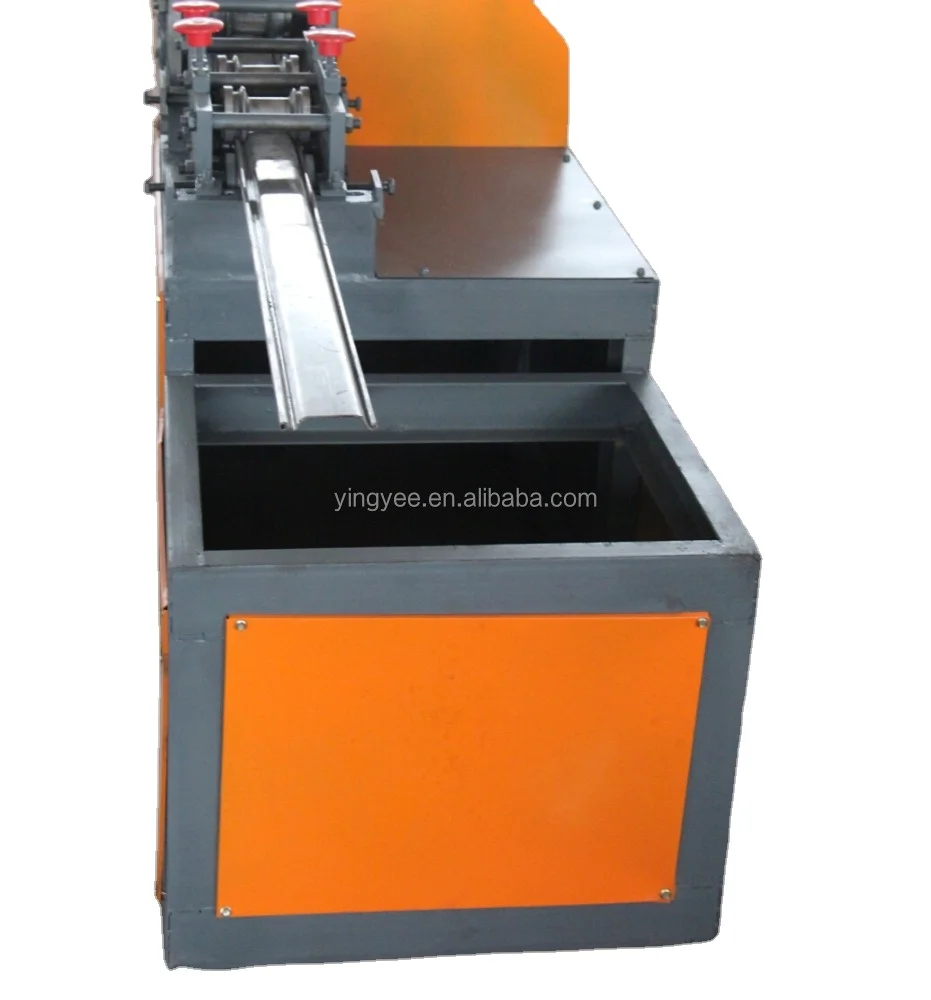

: Built with high-quality steel components for long service life and reliable operation

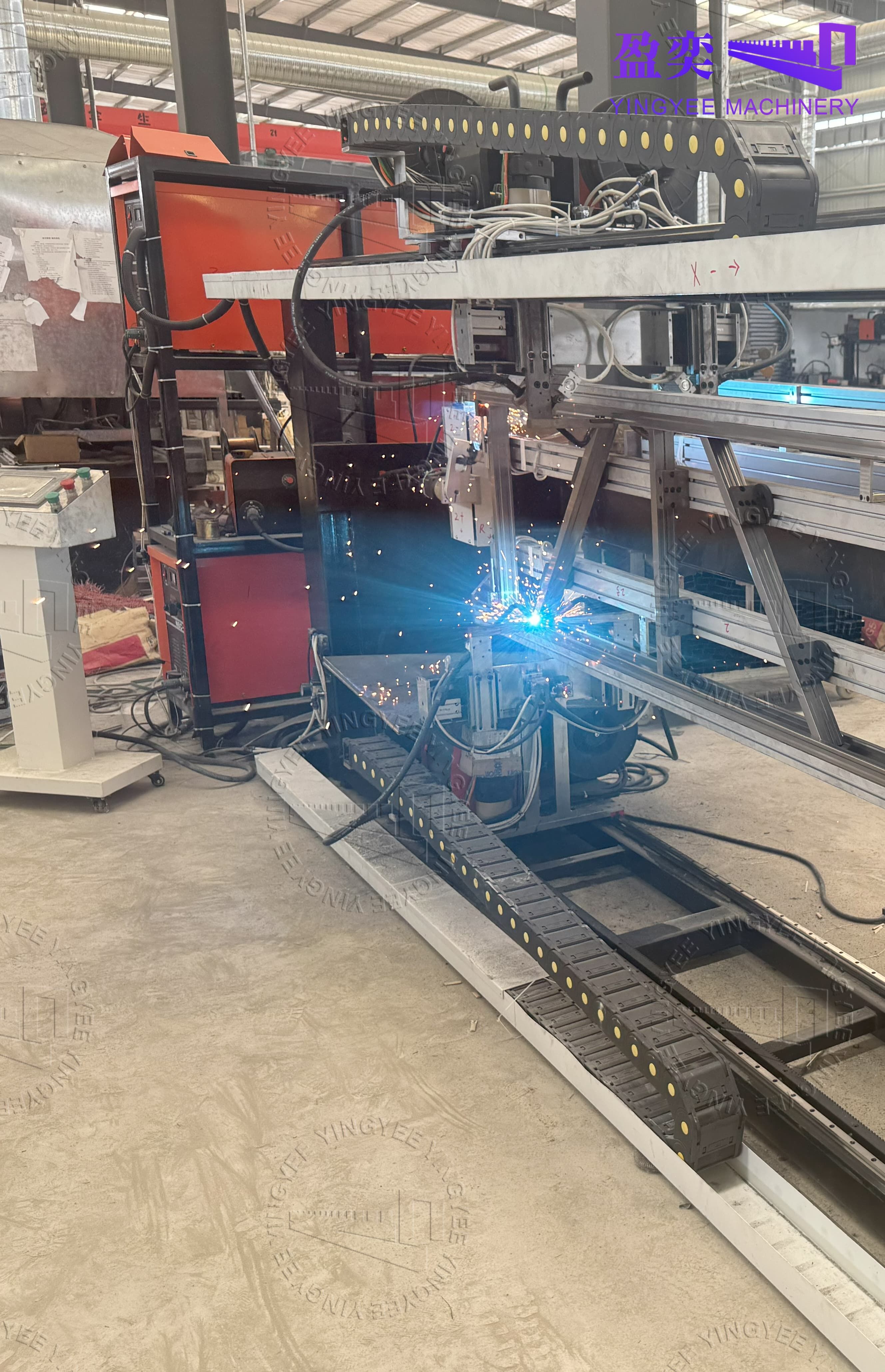

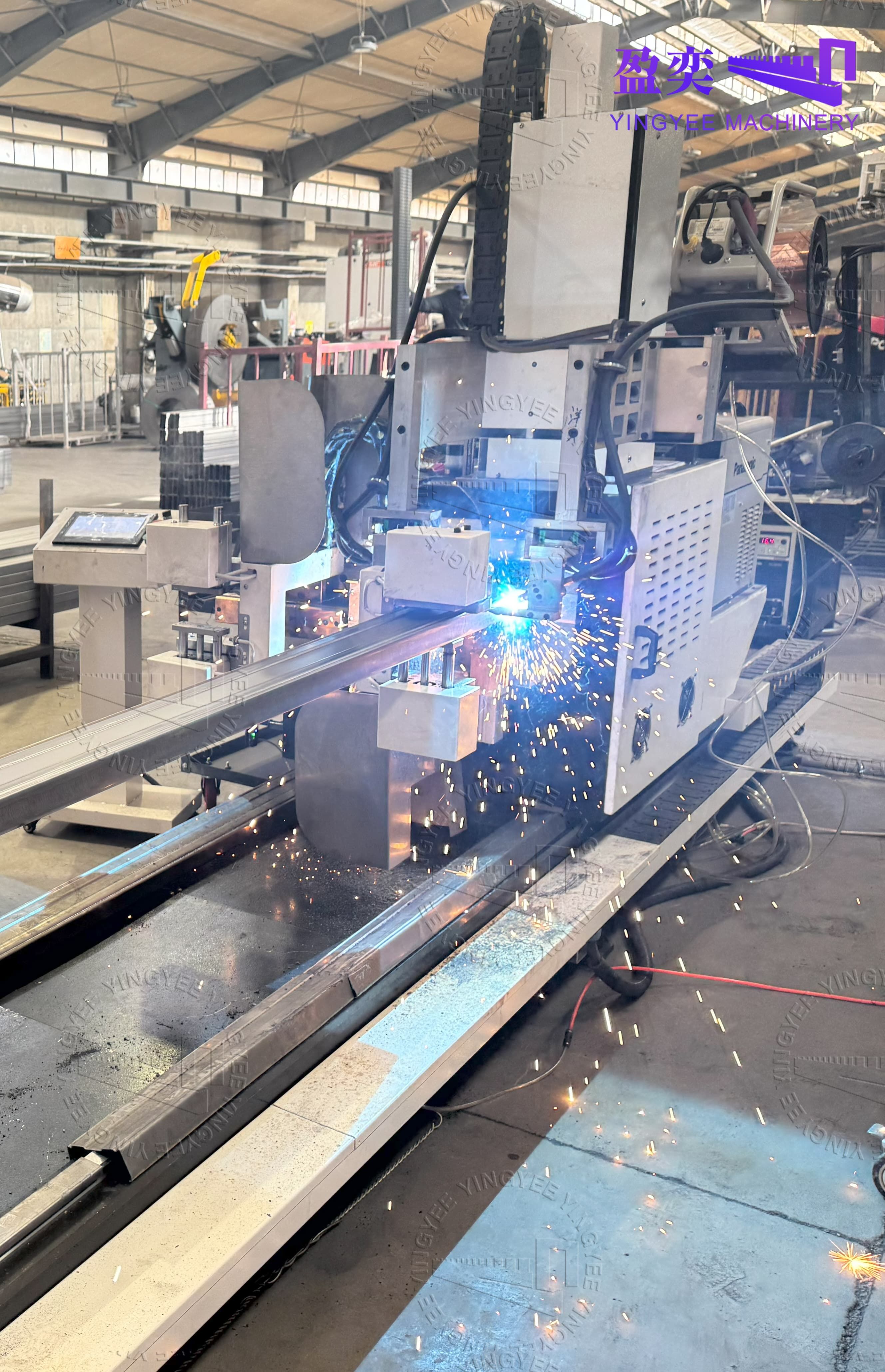

Increased Productivity: The automation of the welding process allows for continuous operation, significantly increasing output.

Consistent Quality: Every weld is uniform and precise, reducing the risk of defects and rework.

Cost Savings: Reduced labor costs and increased efficiency lead to substantial savings over time.

Safety: The machine's design minimizes the risk of accidents, ensuring a safer working environment.

🌐 Wide Range of Applications:

-

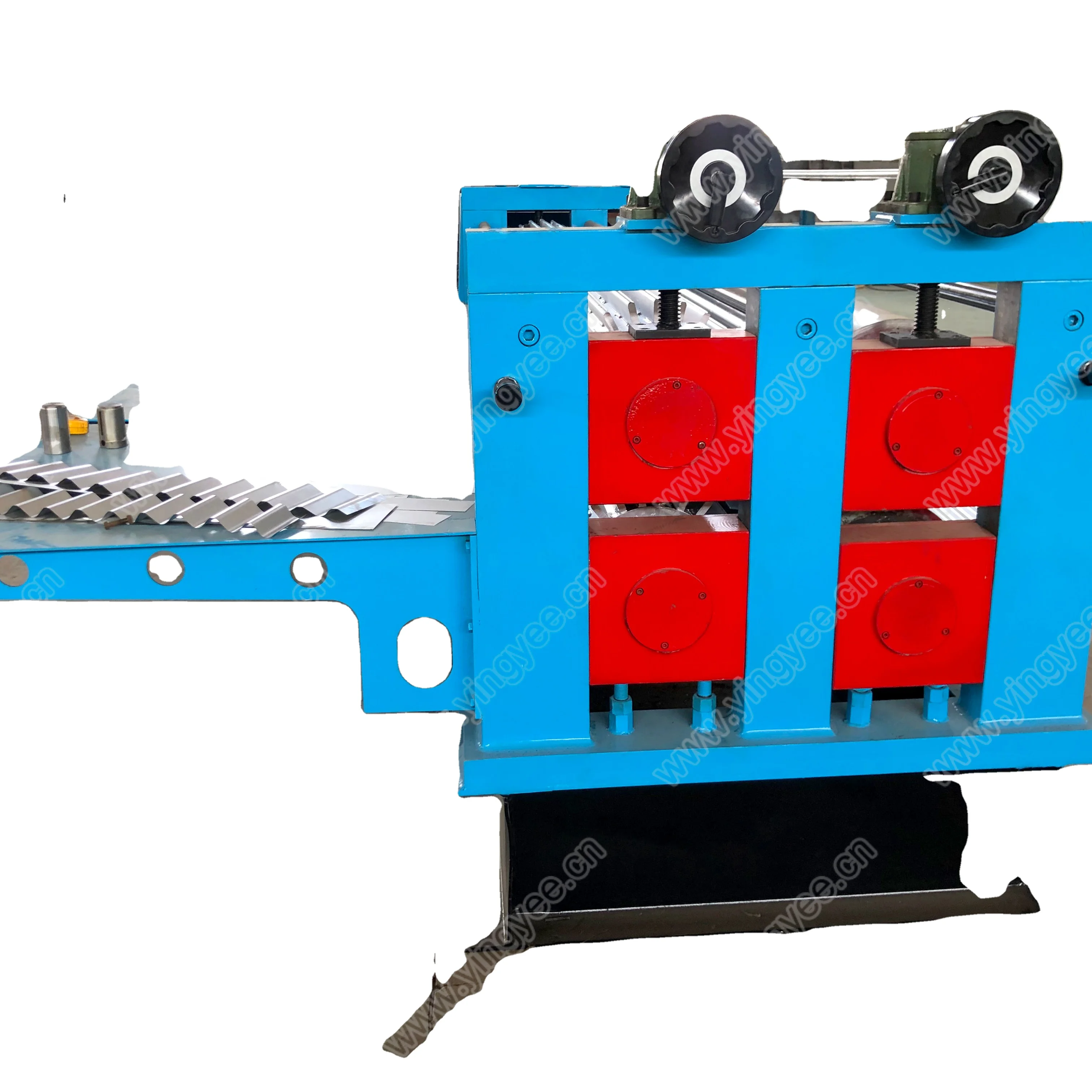

Construction Industry: Manufacturing hooks for scaffolding, support systems, and hanging structures.

-

Furniture Manufacturing: Producing suspension hooks for cabinets, shelves, and modular furniture.

-

Automotive Parts: Fabricating fastening and hanging components for vehicle interiors and accessories.

-

Hardware & Accessories: Ideal for producing industrial hooks, hangers, brackets, and other related parts.

✅ Why Choose Our Side Hook Automatic Welding Machine?

Our machine combines intelligent control, high precision, and user-friendly design, making it the ideal choice for manufacturers looking to upgrade their production lines. With global certifications and successful installations worldwide, our equipment has been trusted by many leading enterprises in the industry.

Let us help you achieve higher productivity, better product quality, and lower operating costs — all with one powerful machine.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY