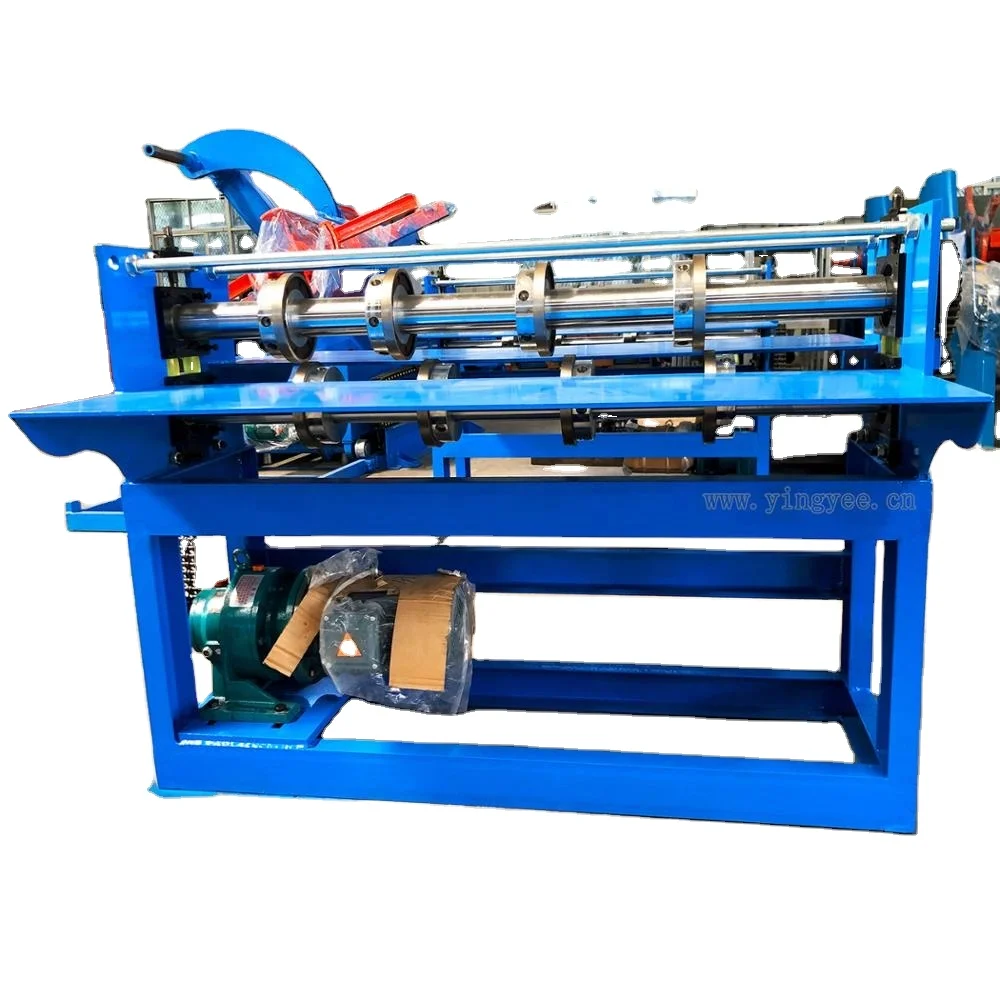

Sabitlemeler, çiviler ve tuğlalardan hiç düşündün mü? Bu küçük bileşenler, köprülerde ve binalarda kritik bileşenlerin yapısal bütünlüğünü koruyarak çok kritiklerdir. (Barrel içinde bağlı, diyebiliriz.) Çiviler, boular ve tuğlalar olmadan dünyanın büyük bir kısmı güçlü ya da güvenli olmazdı. Bu minik bileşenleri üretmek için kullanılan yöntemlerden biri, özel bir tür ekipman ile yapılır ve bu ekipmanın adı soğuk Rulo Şekillendirme Makinesi . Soğuk biçimlendirme, metali odunun sıcaklığında şekillendirdiğimizde yani onu ısıtmadığımızda gerçekleşen işlemdir. Bu süreç, güçlü ve belirli parçalar için kullanılır.

Soğuk biçimleme makineleri bir kalıp aracı kullanır. Kalıp, temel olarak metali istenen şekle dönüştürmeye yardımcı olan belirli bir tür araçtır. Makine, metali içeri besleyerek ve kalıbın metali kesmesiyle metali istenen şekle sokar. Bu şekil verme işlemi birçok kez gerçekleşir - bazen yüzlerce, sıklıkla binlerce kez - aynı metal parçaların pek çok kopyasını üretmek için. Makine tekrarlanabilir parçalar üretir ve her seferinde çok verimli çalışır.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY