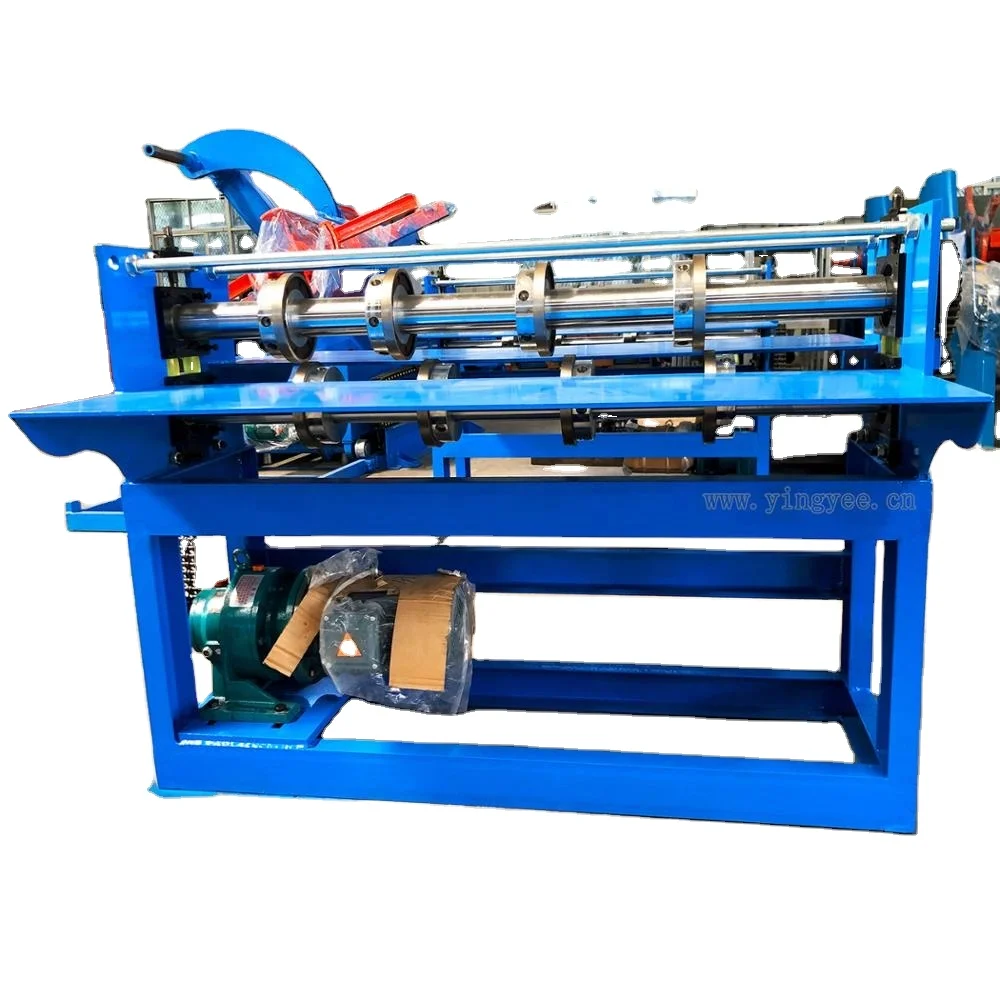

Düz Matris Tel Kaydırma: Bu tel türü, yuvarlak nesnelerin (örneğin çiviler, borular ve vurucular) etrafında bulunan özel bir yöntem ve spirallerdir. Bu, dayanıklı ve güvenilir ürünler üretilmesine yardımcı olan üretimde çok önemli bir adımdır. Çünkü tüm bu fazlar, ürünün sağlam ve güvenilir olmasını sağlar. İçin roll forming machine for sale , iş parçası bir yuvarlak metal parçasıdır ve iki düz araç arasında yerleştirilir. Bu "damlıklar" (damlıklar, oluşturmak istediğiniz çizgilerin kesitine benzer şekillerdedir) metal japonika'ya (şekle bağlı olarak) basarak aynı, düzenli ve sürekli çizgiler oluşturur.

İş parçasını iki damlık arasında yerleştirdikten sonra, dönmeye ve kaymaya başlar. Metalin damlıklar tarafından şekillendirilmesine izin veren bu hareketin çok önemli olduğu açıktır. Yuvarlak parça damlıkların arasından geçerken, damlıklardaki şekiller metalin üzerine damgalanır ve bu süreçte çizgiler oluşturulur. Bu çiviler inanılmaz derecede doğru olup, nesnelerle mükemmel bir şekilde uyumlu yüksek kaliteli çizgiler üretir. Birçok uygulamada, çizgilerin doğru oluşturulması kritik öneme sahiptir ve bu süreç o güvenceyi sağlar.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY