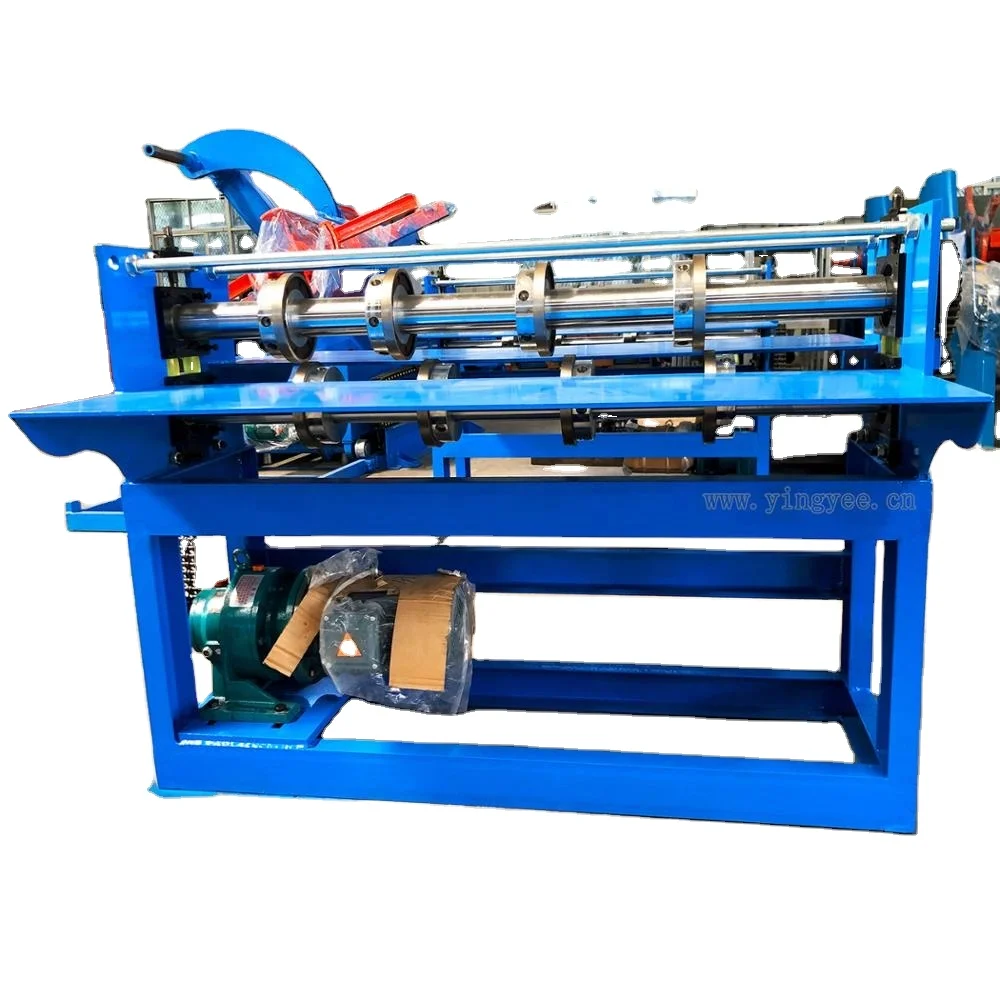

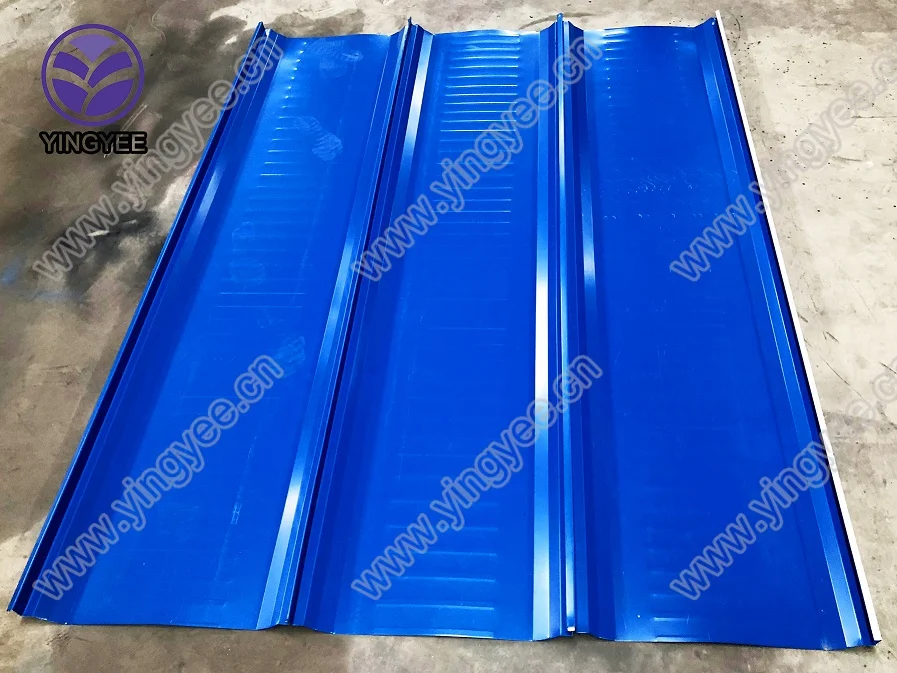

Bir metal levhasının veya bir metal borunun nasıl şekillendirildiğini merak etmiş misiniz? Hidroform makinesi — A roll forming machine for sale metali çeşitli şekillerde şekillendirmek için kullanılan özel bir araçtır. Metal ürünleri üreten fabrikalar bu makinelerden çok bağımlıdır. Hızlı ve verimli metalurji sürecini basitleştirirler.

Bu, hidroform adı verilen özel bir süreç kullanarak metali şekillendirdiğini anlamına gelir. Yüksek basınçlı sıvı (su) kullanılarak metal levhalar ve borus şekillere dönüştürülür. Bu da, parçaları kırmak veya kaydetmek yerine (örneğin, bir pres makinesi bunu yapardı), makinenin tek bir hareketle güzel formlar oluşturabileceğini ifade eder. Kaydetme gibi normal metal şekillendirme süreçlerinden hem daha hızlı hem de daha iyidir çünkü kaydetme uzun sürer ve işgücü açısından yorucudur.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY