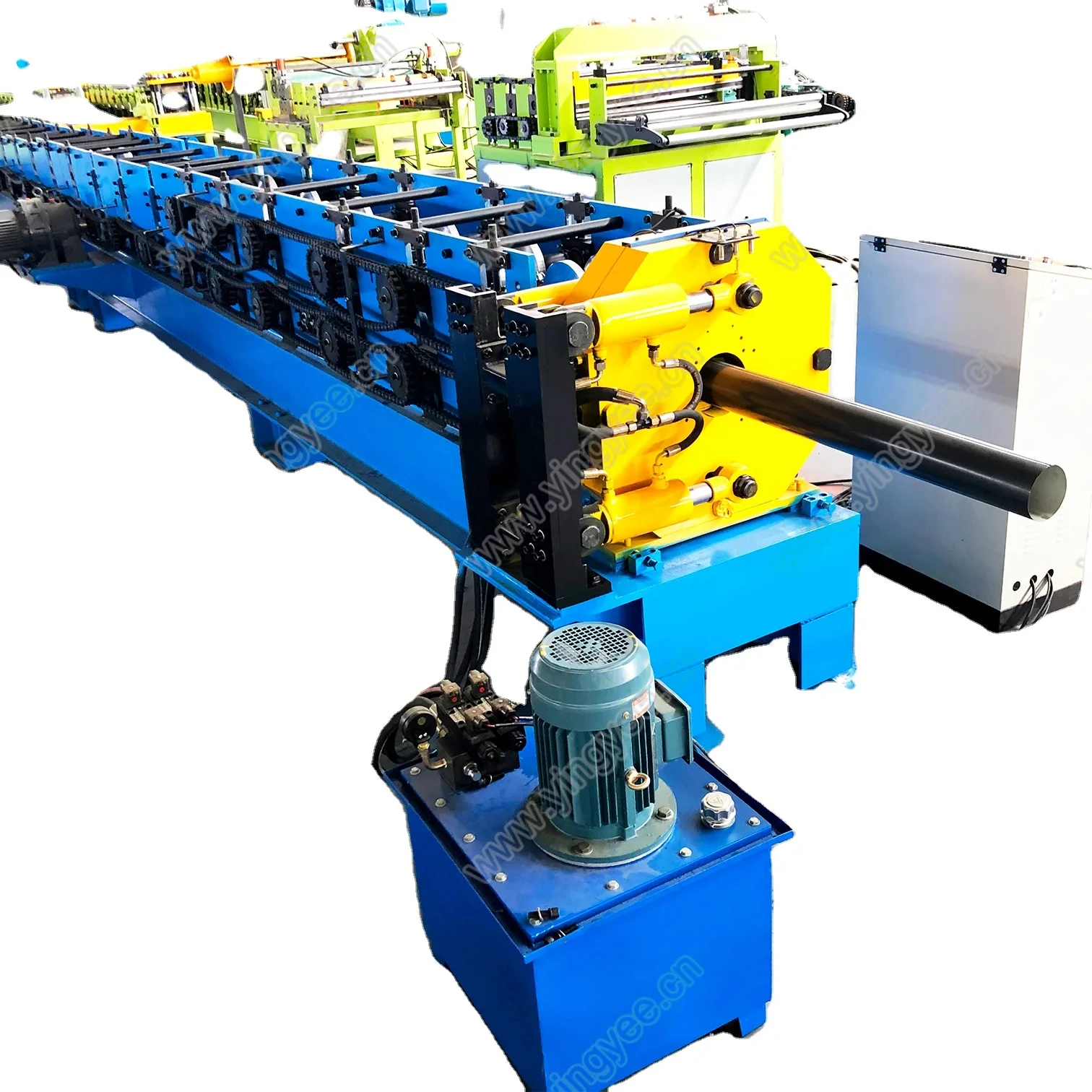

Binalar, araçlar ve diğer yerlerde gördüğümüz bazı metal formların nasıl oluşturulduğunu merak etmiş misiniz? Bu konu oldukça ilginç! Bu metal şekilleri oluşturmak için en iyi seçen olan bir Metal Rulman Makinesi adlı uzman bir makine kullanılır. Çok, çok hızlıdır—saniyeler içinde güçlü ve doğru metal şekiller üretebilir. Ayrıca çevreye fayda sağlayacak şekilde neredeyse hiç atık bırakmaz.

Metal Rulman Formunda süreç oldukça basittir. İşlem şu şekilde yapılır: Makine, bir çelik levhası gibi düz bir metal parçasıyla başlar ve bunu özel şekilli rulmanların bir dizisinden geçirir. Bu rulmanlar metali yavaş yavaş istenen forma bükür, tamamen bir bulmaca parçasının yere oturması gibidir. İstenen son şekil ve tasarım, kullanılacak rulmanları belirler. Bu yaklaşımda daha yumuşak metallere, özellikle alüminyum, çelik veya bakır gibi kolayca bükülebilen metallere uygundur.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY