Bir Sandviç Panel Üretim Hattı, İnşaat İşletmenizi Nasıl Devrimlendirebilir

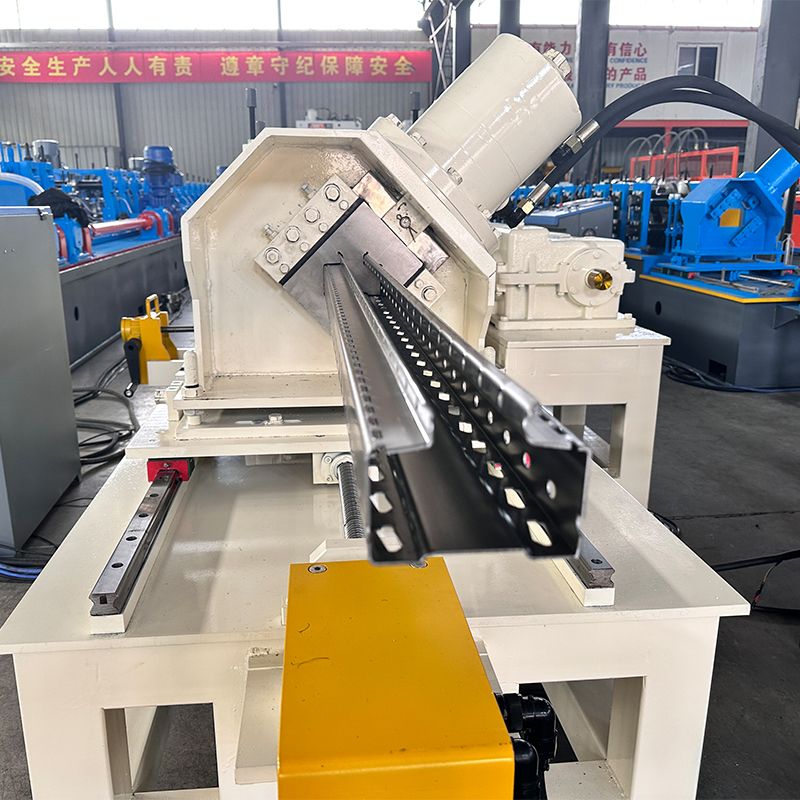

Bir sandviç panel üretim hattı, inşaat işletmenizin çalışmasını olduğu gibi yapmasını devrimleştirebilir. Bu, verimliliğine her zaman katkıda bulunarak, makinaların sürekli çalıştığından ve birçok panelin fazla gecikmeden üretilmesinden emin olur. Her seferinde harika ürünler elde etmenize olanak tanır. Bu üretim hatları, son derece dayanıklı ve uzun ömürlü makina hattıdır—yüksek saatler çalışmak için tasarlanmıştır ve birçok durumda bir günün 24 saati boyunca çalışabilir! Bu, ürün üretmeyi tekrarlayabileceğiniz anlamına gelir, mola verme gereksinimi olmadan. İşletmenizi güncel tutmak ve yüksek hacimde ürün üretebilmek için YINGYEE, farklı seçeneklerle bir dizi makine sunmaktadır.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY