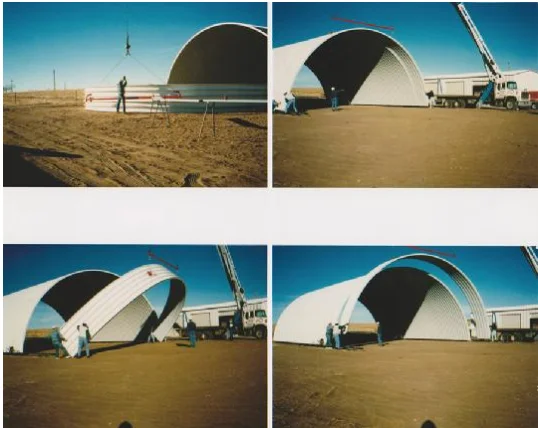

Kapılar gibi yukarı inip aşağı indiği için pencere gibi görünen büyük metal kapıların birini hiç gördün mü? Bu, şömine kapısı olarak adlandırılan kapı türünün biridir! Farklı türde şömine kapıları vardır; bunlar mağazaları ve depoları dışarıdan gelen risklerden korumak için kullanılan büyük kapılardır. Ama bu kapıların nasıl yapıldığını hiç düşündün mü? Hadi bulalım!

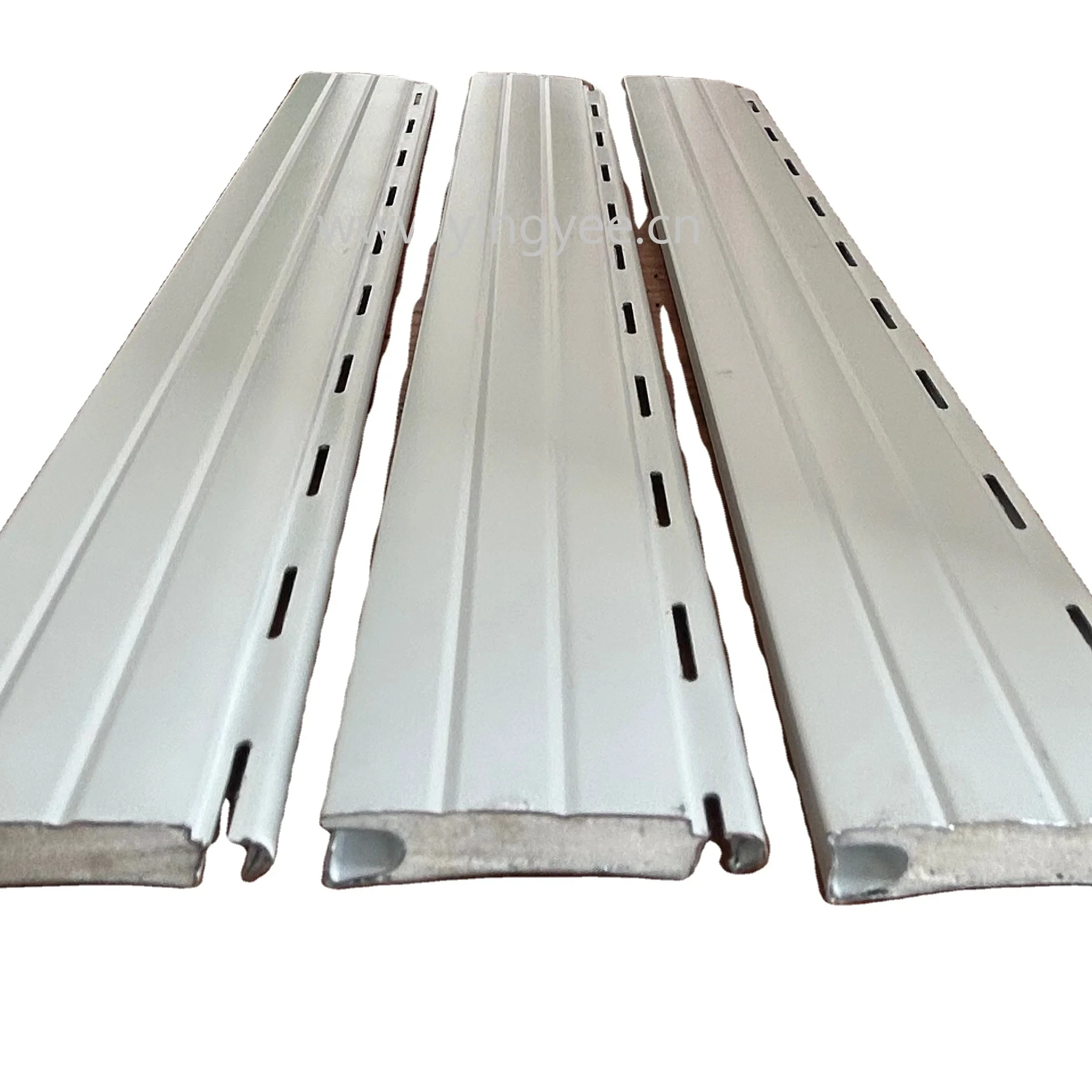

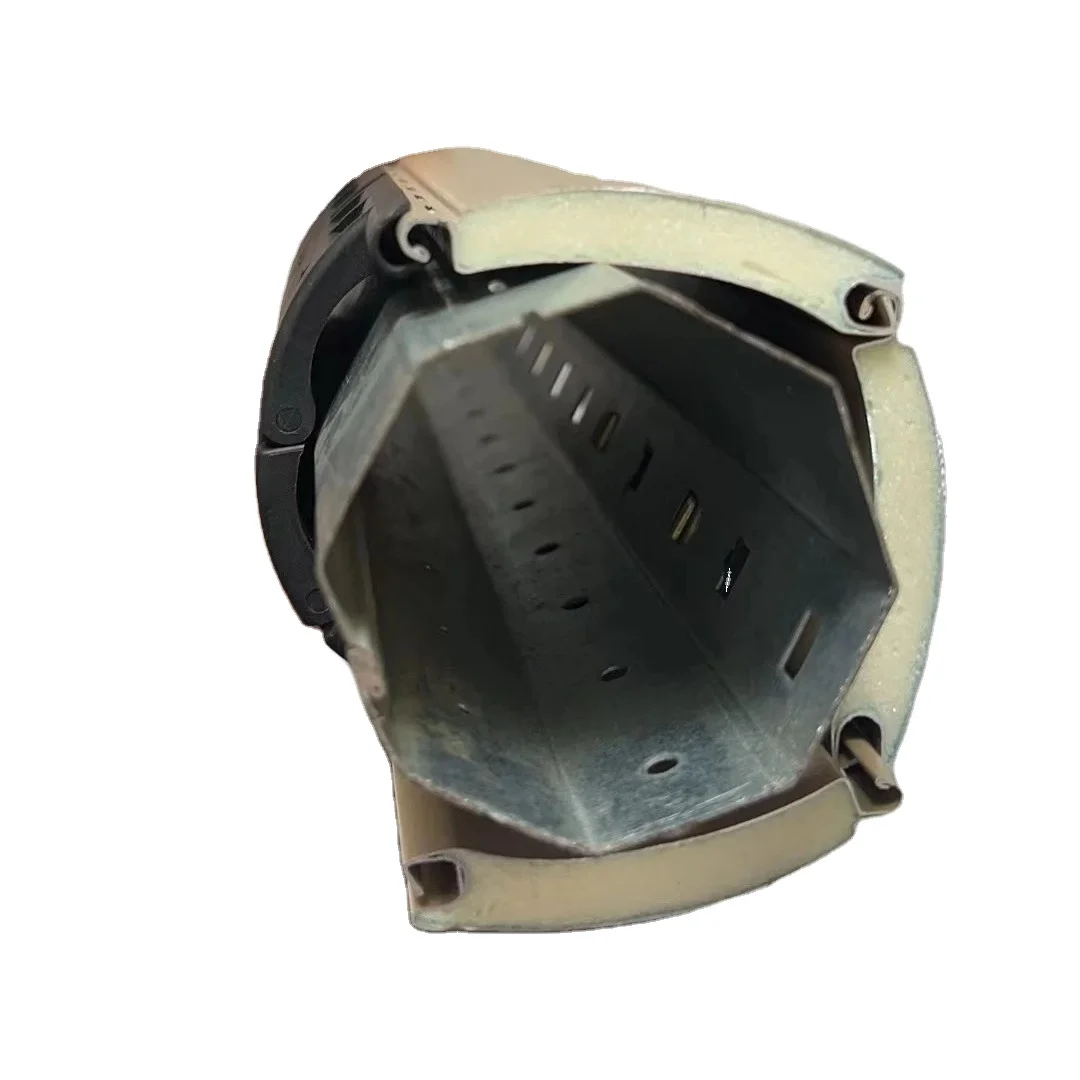

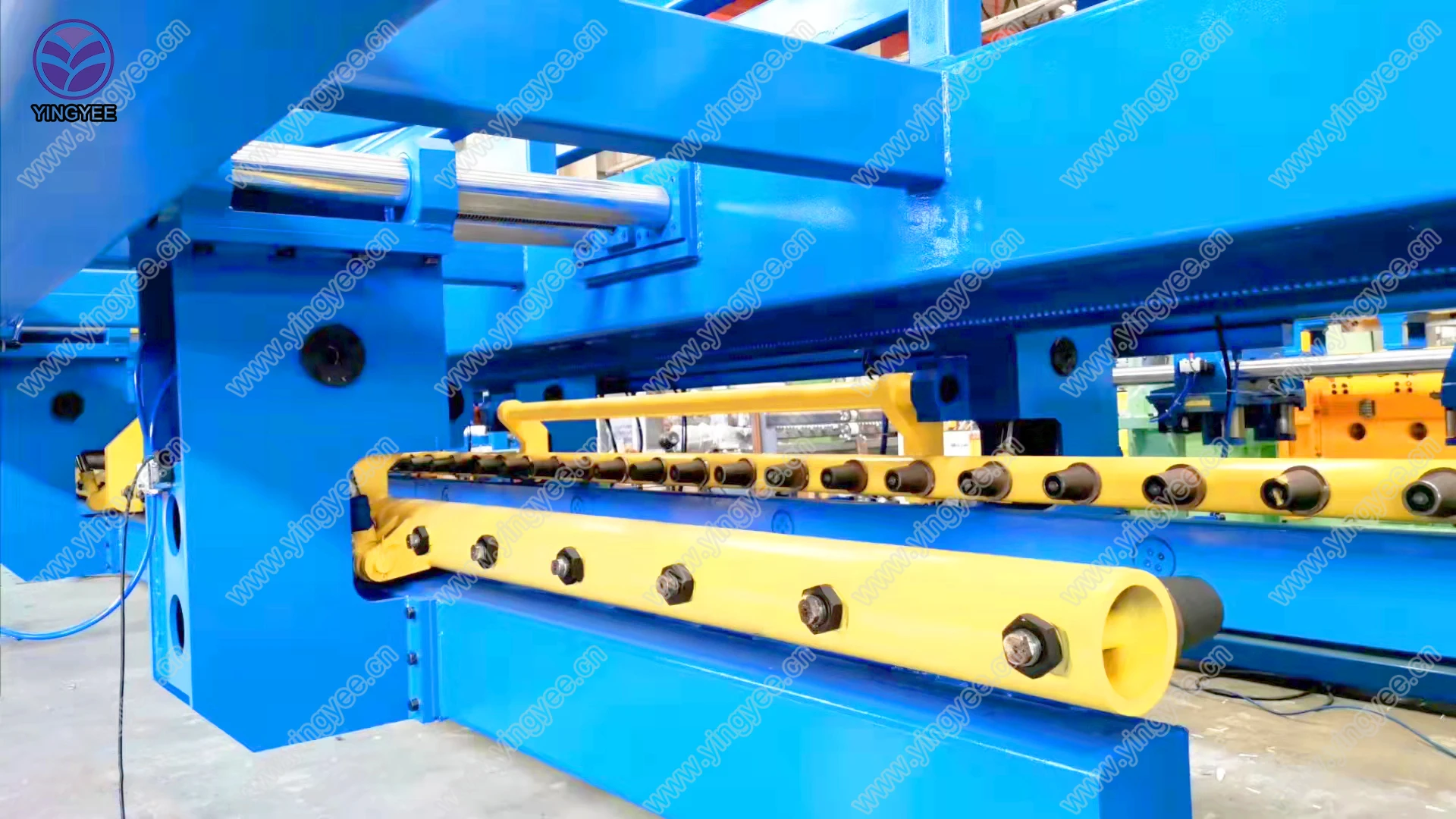

Eski yöntemde, insanlar şömine kapısını elle yapıyordu, bu da zaman alıcı ve enerji tüketici bir süreçti. Peki şimdi YINGYEE gibi özel makinelerimiz var ki, şömine kapısı üretimini çok daha kolay ve hızlı hale getiriyor! Bu makineler, şömine kapısı üretimini hızlı ve verimli bir şekilde yapmak için modern öncü teknolojileri kullanır, böylece işlem daha hızlı yapılır.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY