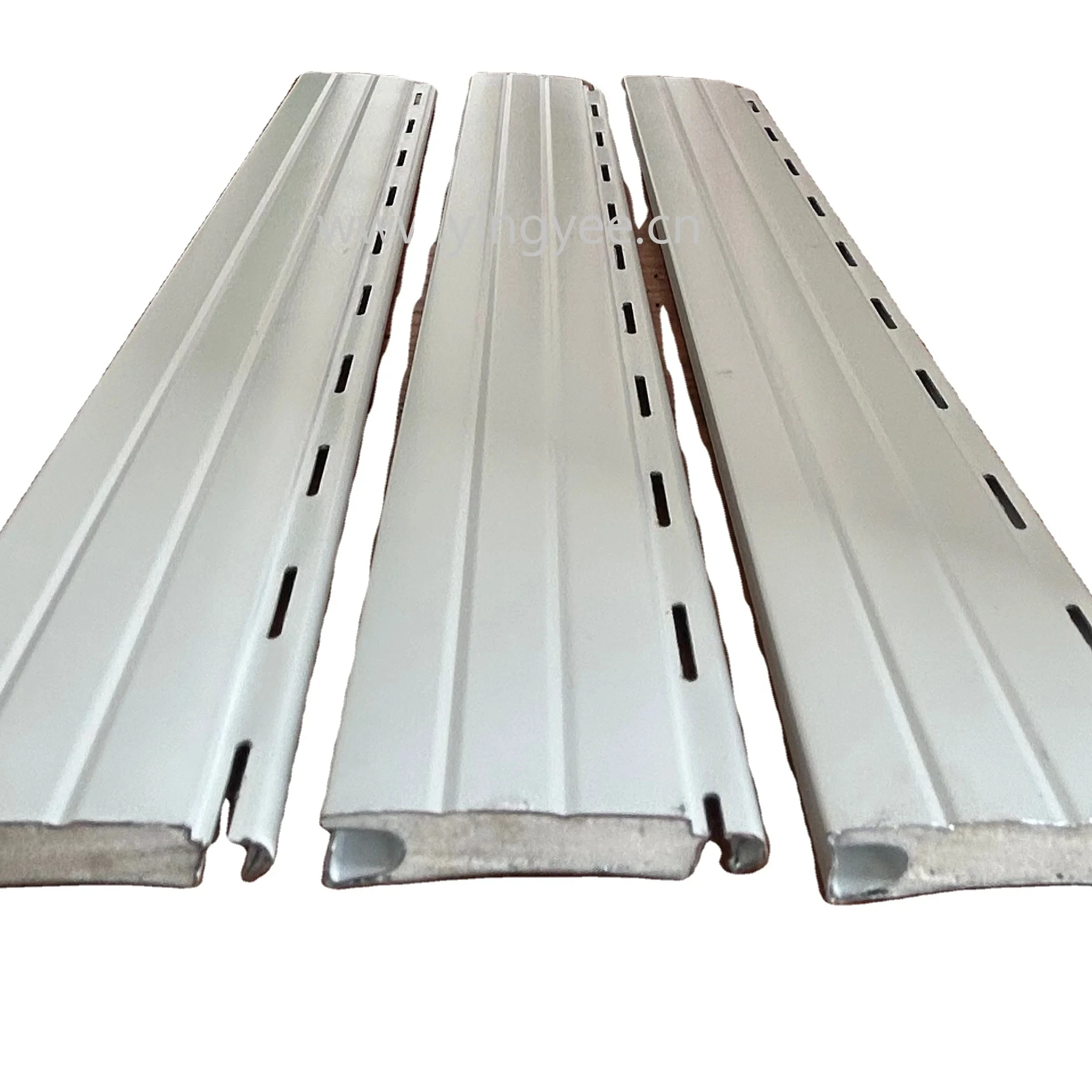

Product brief description

| Items |

Spec: |

| Material |

1. Thickness:0.3-0.8mm

2. Input width:according to the drawing

3. Effective width: according to the drawing

4. material: GI strips.

|

| Power supply |

380V, 50Hz, 3 phase ( according to customer request) |

| Capacity of power |

1. main power:5.5KW

2. hydraulic power:3kw

3. servo motor power:2.2kw

|

| Speed |

Line speed:0-40m/min |

| Total weight |

Approx. 3-4 tons |

| Dimension |

Approx:4.0m*1m*1.2m |

| Stands of rollers |

10 roller stations |

| Driven |

Chain |

| Cut style |

No stop cutting with servo control with 1.2m guide |

Product details description

1. 3 tons manual de-coiler uncoils strip.

2. The strip enters the forming part through the feeding part, and the folding

is completed in the forming part.

3. After forming,. then cut.(No-stop cutting. Tracking moving cutting by servo

control)

4. Collection table

Product parameters table

| 3 tons manual decoiler |

Capacity:3000kgs

Inner diameter of coil: 440-500mm |

| Roll forming machine |

Max thickness: 0.3-0.8mm

Main power:5.5KW

Forming speed:40m/min

Shaft material: 45 #steel;

Shaftdiameter:50mm;

Rollers material: Cr12;

Roller Steps:10steps;

Machine structure: Torrist

Drive: Chain;

Voltage:380V 50HZ 3PH

|

| Cutting and punching

(hydraulic guide) |

No stop cutting(1.2m guide)

Cutting motion: Servo motor no stop cut.

Material of blade: Cr12 mould steel with quenched treatment 58-62℃

|

| PLC control system |

Automatic length measurement:

Automatic quantity measurement

Computer used to control length & quantity. Machine will Automatic length measurement

Automatic quantity measurement

Computer used to control length & quantity. Machine will

|

| Collection table table |

Manual collection table |

| Electronic part |

1. Inverter:Made in China

2. Servo motor:Made in China

|

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY