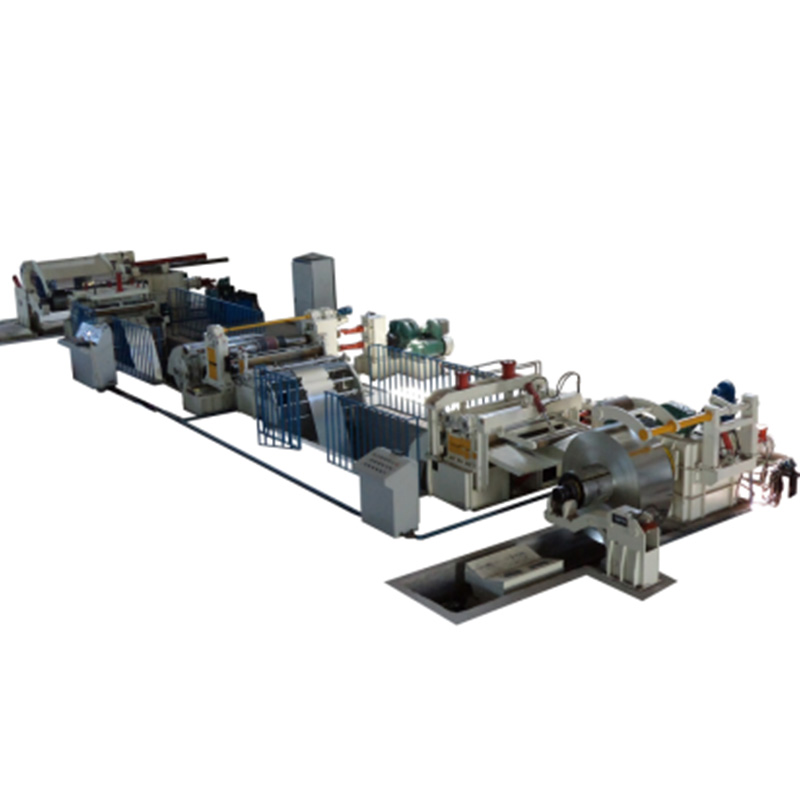

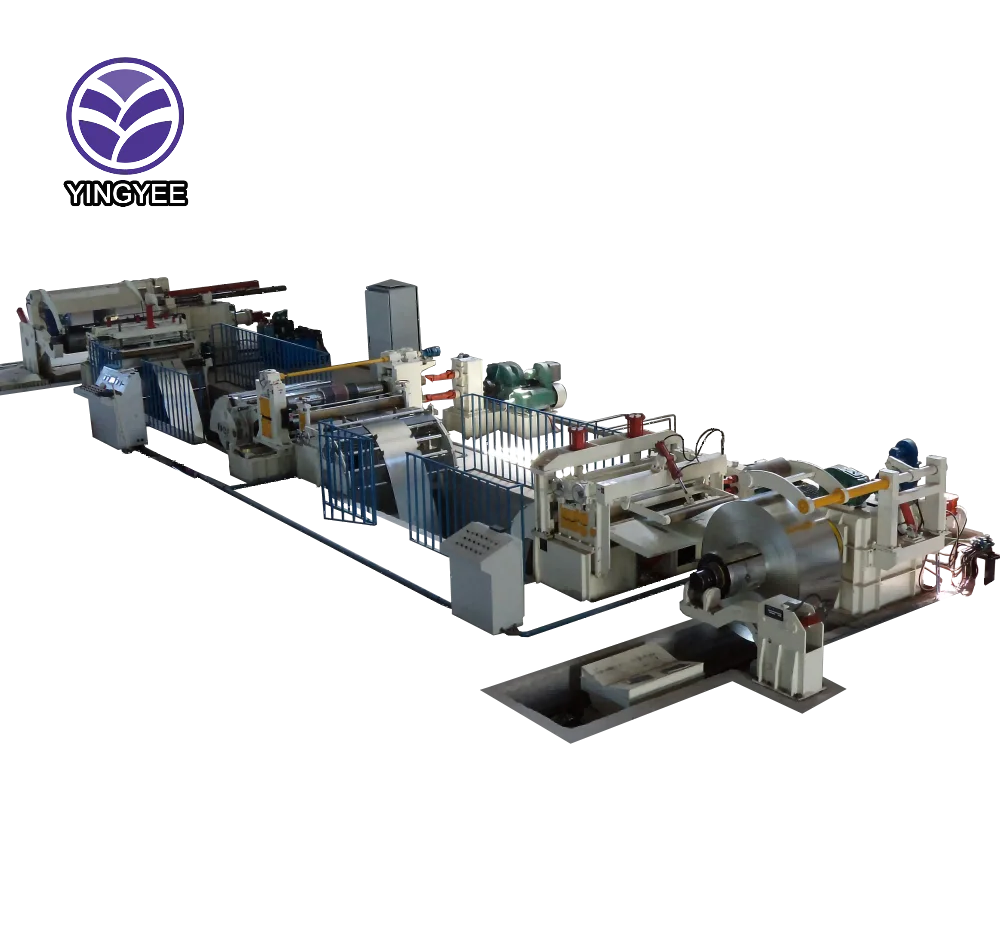

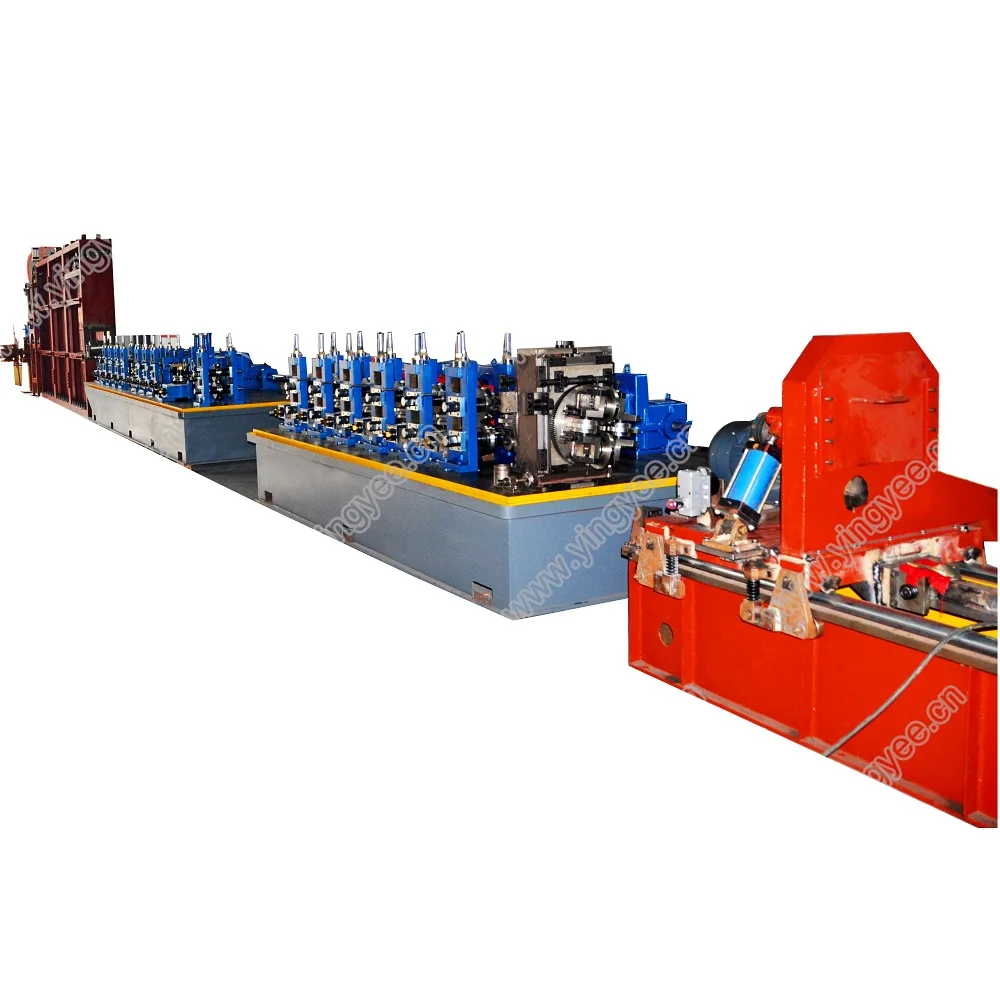

Streamlining Production with a Coil Cut to Length Line

Yet another advantage of the use of a coil cut to length line, is that it allows factories to save money. Automating the cutting process allows factories to minimize waste. This can enable them to bring down their production costs and widen their profit margins. It is also extremely accurate meaning that there is very low risk of mistakes or errors in the cutting process.

Production with a coil cut to length line can also allow factories to simplify their production. Instead of requiring two different machines for cutting and measuring, the coil cut to length line is capable of performing both functions in one machine. This can allow factories to save space on the factory floor, and to make it easier for workers to use the machine.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY