Features and Benefits of Cable Tray Roll Forming Machine

The benefits of using a YINGYEE cable tray machine It can, for example, help you create trays far quicker than handmaking them. This swiftness can lead to time and financial savings. It also means having fewer workers on your team, reducing labor costs. Besides, this is a very efficient machine when it comes to using materials so a lot less waste. This is good for the planet and your budget! The last part is that the machine generates quality products that meet the expectations of your customers. In the long run, this machine is definitely a winning investment that plays a role in your progressive business growth.

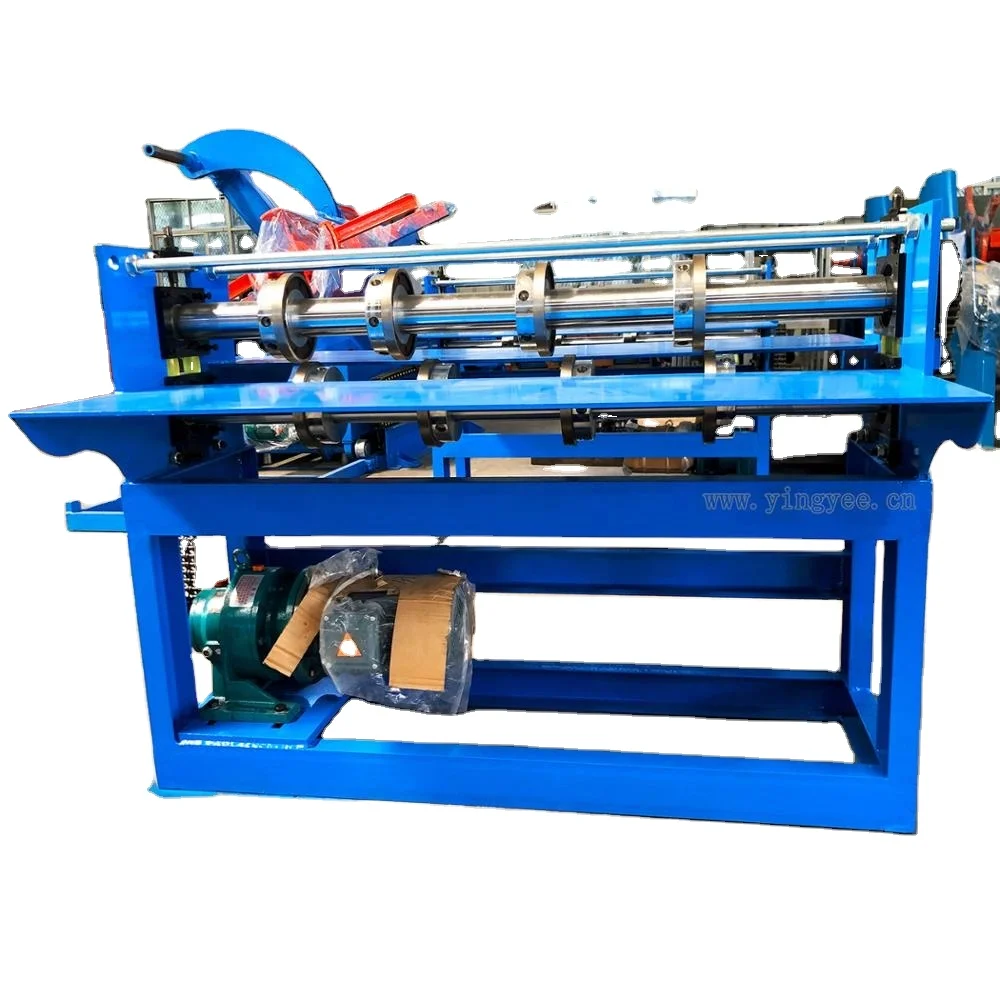

And now, let’s get down to the working principles of a YINGYEE cable tray roll forming machine. It starts with forming raw materials such as steel or aluminum into the machine. Once inside the machine, rollers will shape the material into its final form. Depending on what the customer needs, this can be an open tray, which has no top, or a closed tray, which is completely covered. The machine is super precise as we want the tray for each sample to be identical.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY