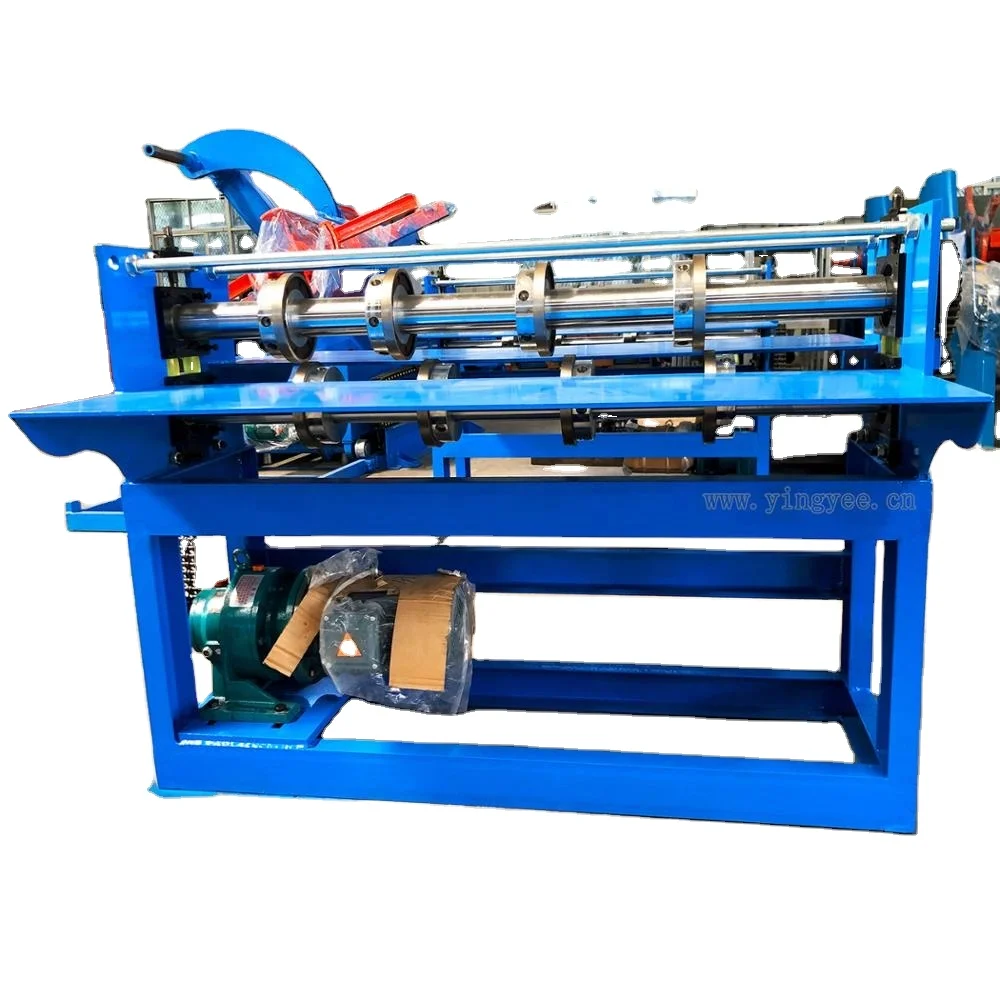

Of screws, bolts and nuts, have you ever thought? These small components are critical, as they maintain the structural integrity of critical components within bridges and buildings. (Bound in the barrel, apparently, one might say.)Without screws, bolts and nuts, much of the world would not be strong or safe. One of the methods to manufacture these minuscule components is through a particular type of equipment named a cold roll forming machine. Cold forming refers to when we are shaping the metal at room temperature i.e. we are not heating it. This proces has a part for strong and specific.

Cold forming machines employ a die as a tool. A die is essentially a specific type of tool that assists in shaping the metal into the desired shape. The machine shapes the metal into the desired shape by feeding the metal in and the die cuts the metal. That shaping process occurs many times — sometimes hundreds, often thousands — to produce many copies of identical metal parts. The machine produces reproducible parts and works very efficiently each time.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY