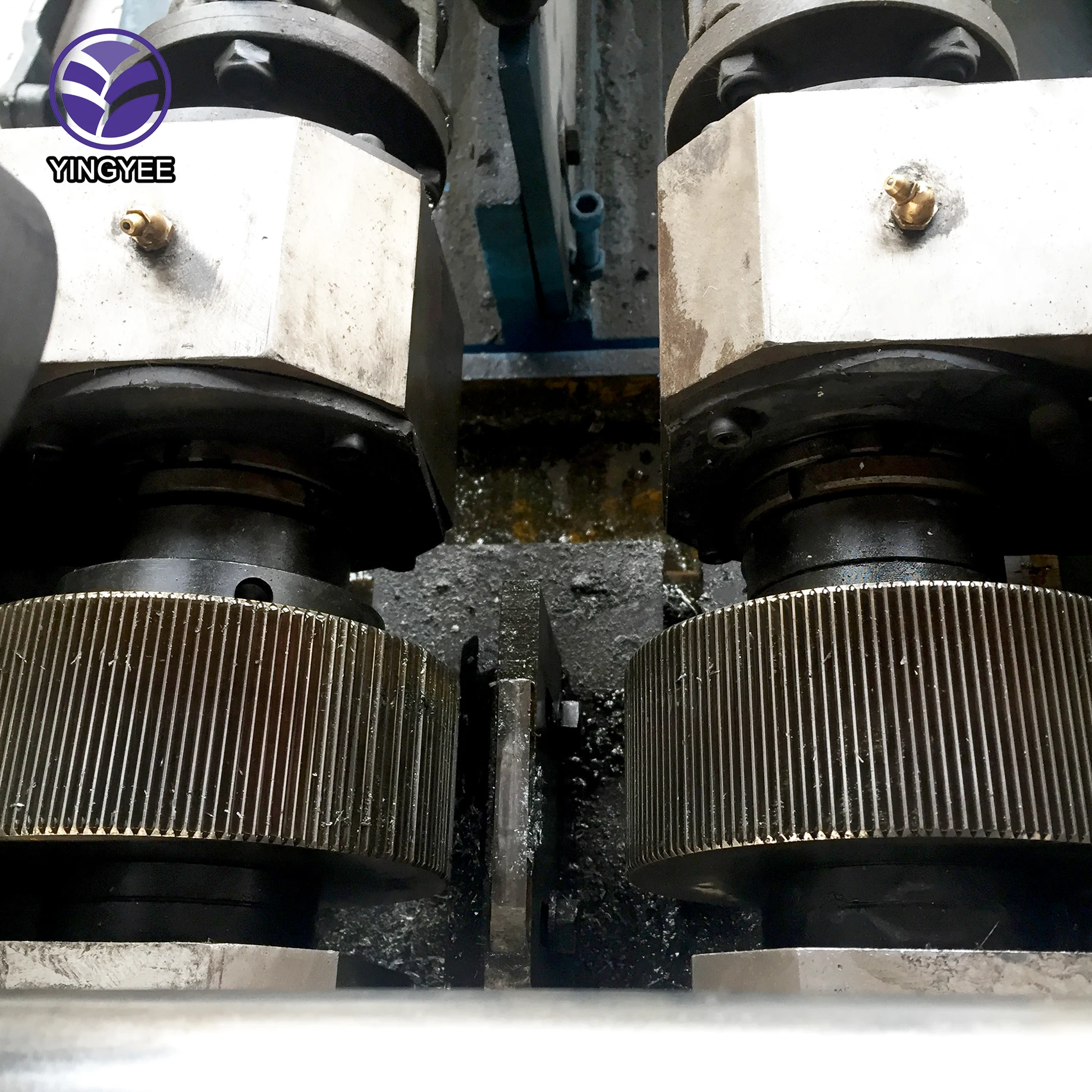

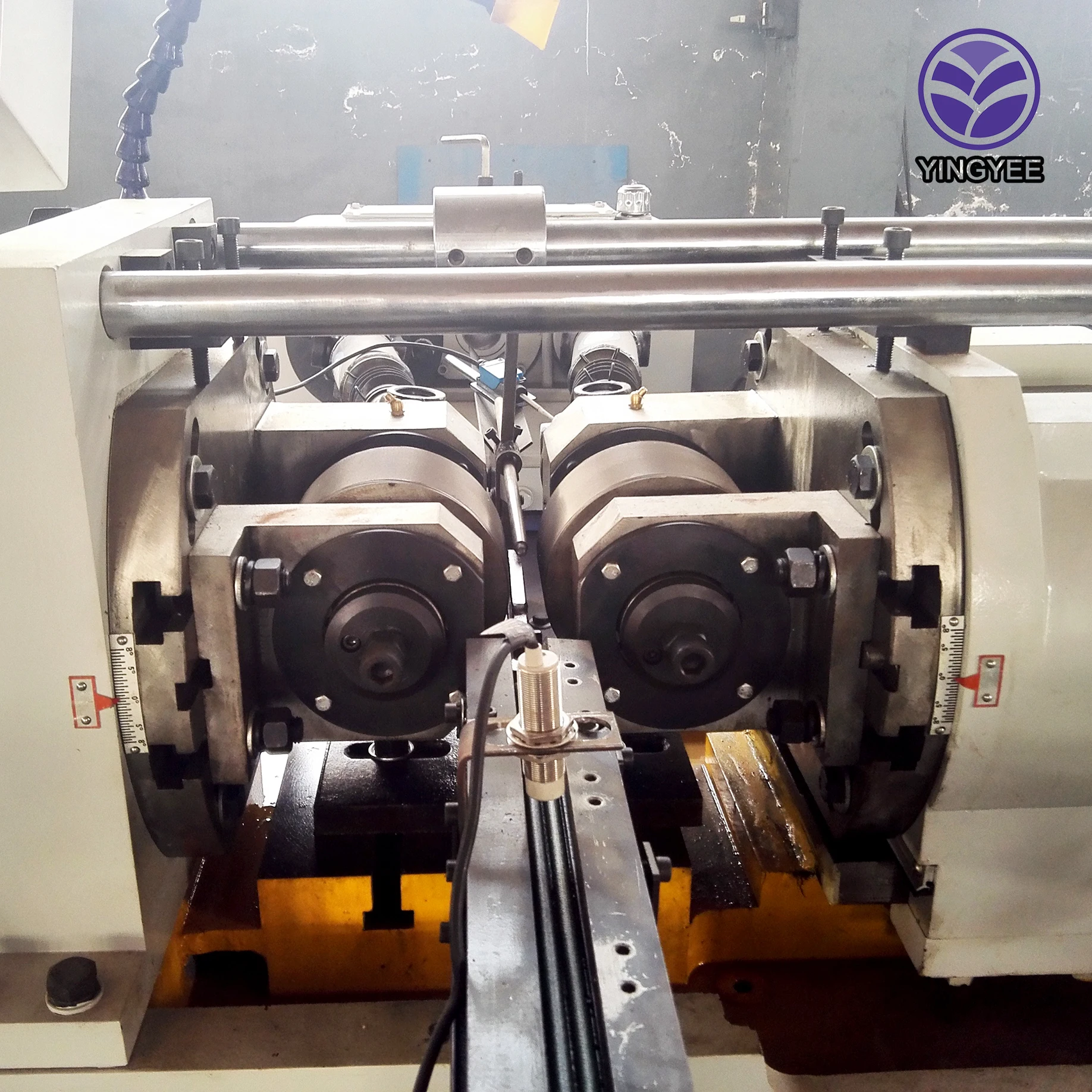

Ever pondered how nuts and jolts are made? They are the small, but significant pieces that keep everything in our day to day world where they need to be. Thread Rolling Machinery: They are manufactured by machine tools, also known as thread rolling machinery. What these machines never do however is cut threads into the material. Instead, the material flows into dies that shape and press it to create threads. The reinforces method improves the durability and longevity of threads, which is critical if you are using them in many different products.

Pre-automationInstallation of the machining material in a machine was done by hand before automatic machines came to exist. They even had to adjust the settings for it all to function properly. The process consumed the humans, who became weary and consequently slowed down. On the contrary, with automated machines today the material goes into machine itself. The jobs can warehouse setting is fixed and preconfigured settings that employees do not have to change. This saves workers plenty of time and strength, so the whole lot turns into quicker at work.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY