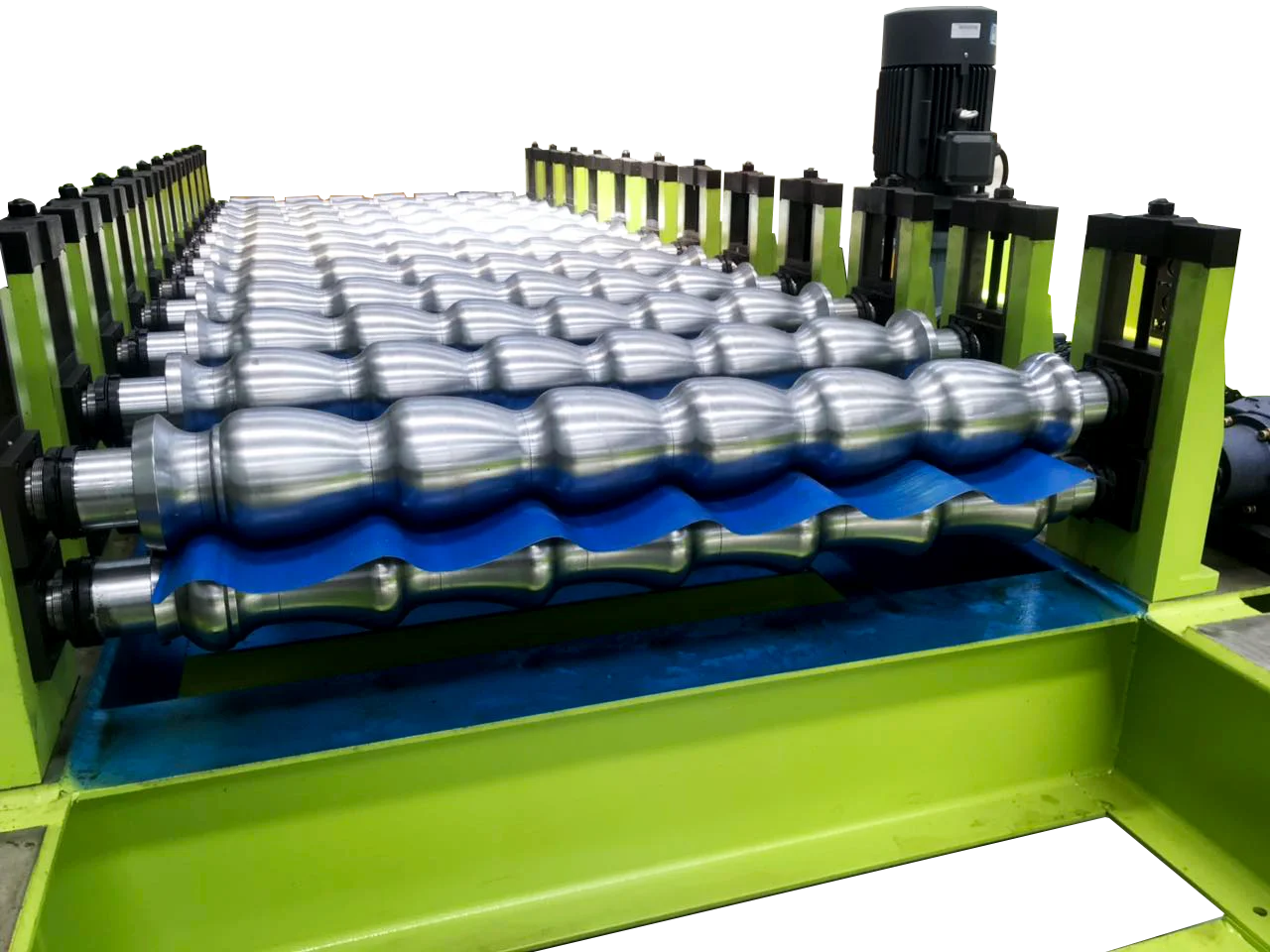

Hi there! Ever heard of a standing seam metal roofing machine? Special equipment for making metal roofs for residential as well as buildings and other structures. In this day and age, it would only be fair that we learn a little more about this wonderful machine and all the advantages it could bring.

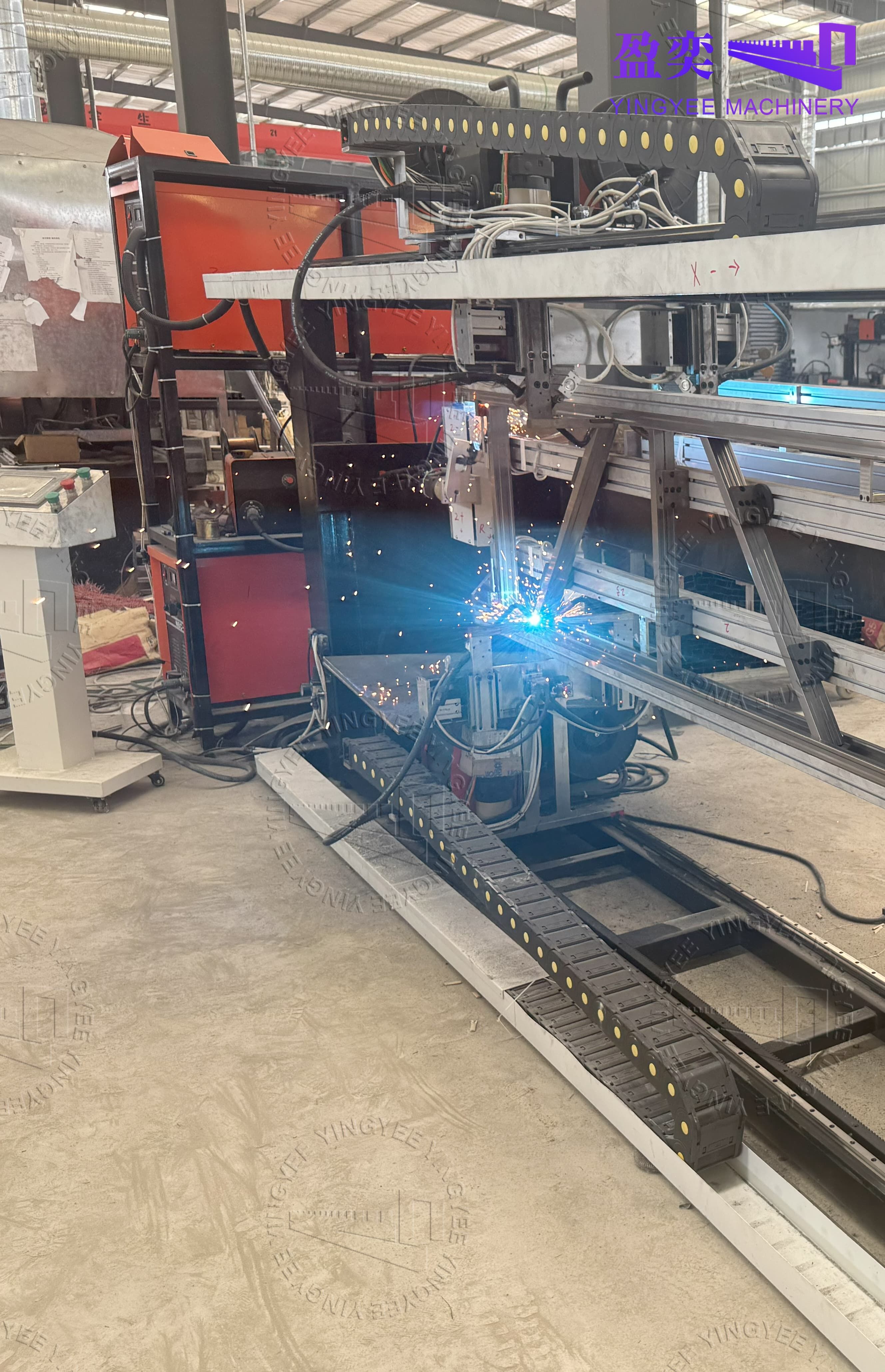

One of the best things about using a standing seam metal roofing machine. Before we take you to the benefits, It will be better if let us discuss how it can save your time and money. Attached and trimmed, this machines sole purpose is to expedite the process of producing metal roofing panels so that they can end on top a roof (figuratively speaking). This is in contrast to the normal, worker-intensive method of fully-forging each panel by hand which can be far more time consuming and expensive. This machine can greatly speed things up, a huge benefit for workers and builders!

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY