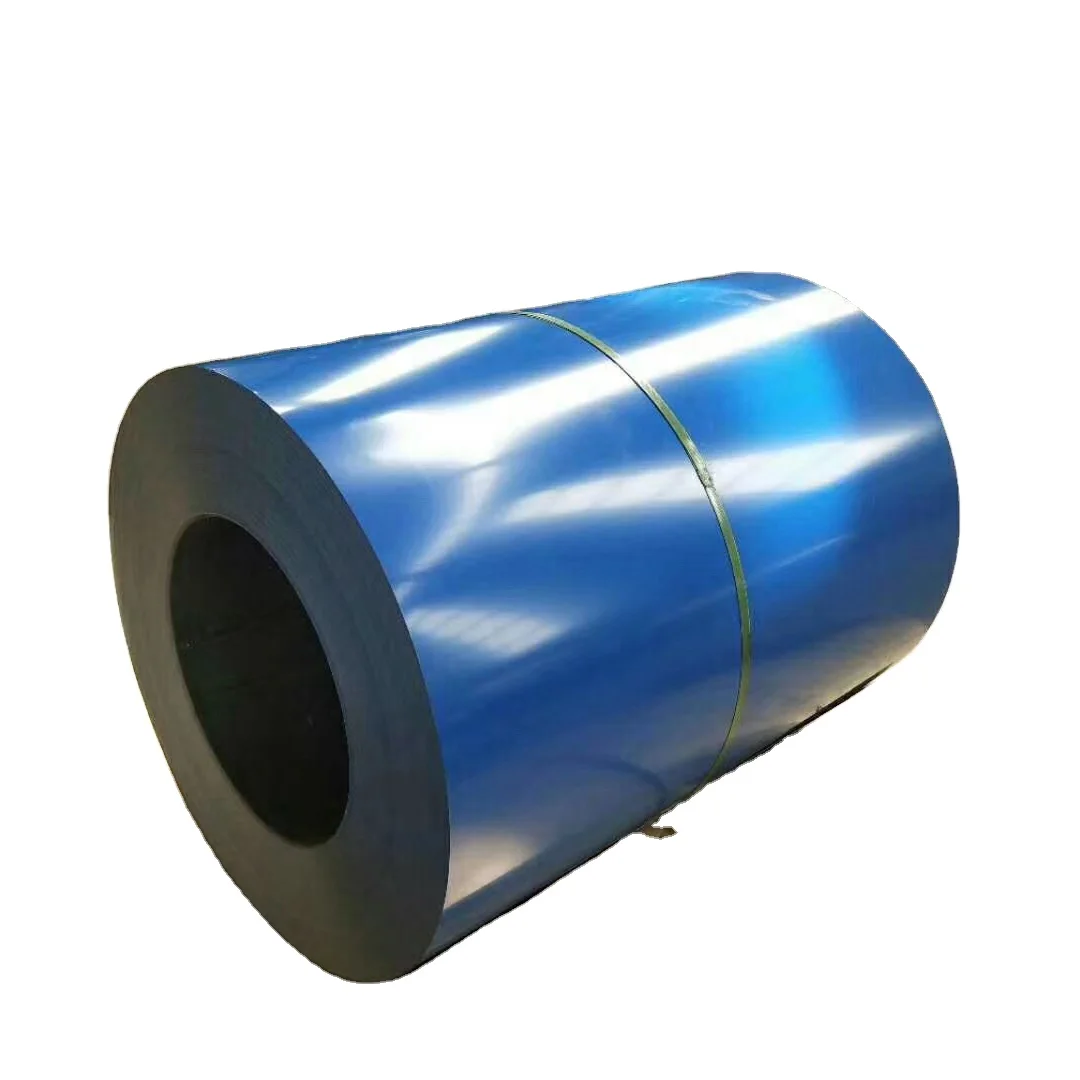

YINGYEE has developed some unique machines that work great for cutting metal coil. Such machines are called steel coil slitting lines. They are used to cut big rolls of metal, known as coils, into long and thin strips. You can get strips for a variety of use cases in a range of products. Metal coils are typically formed of such metals as steel, aluminum, and stainless steel. These are significant materials and are extensively employed in sectors (like automotive (vehicles), construction (structures), and aerospace (aircraft)).

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY