Iron ore lies beneath the earth's surface. Workers harvest it and drop off at a factory. The iron ore is then heated in a factory until it melts and becomes liquid. Molten metal this is the new hot liquid steel poured into various molds to create shapes in many forms e.g. stats or sheets etc. These shapes are then shaped into long, slender strip of Steel whichcan be utilized for numerous applications.

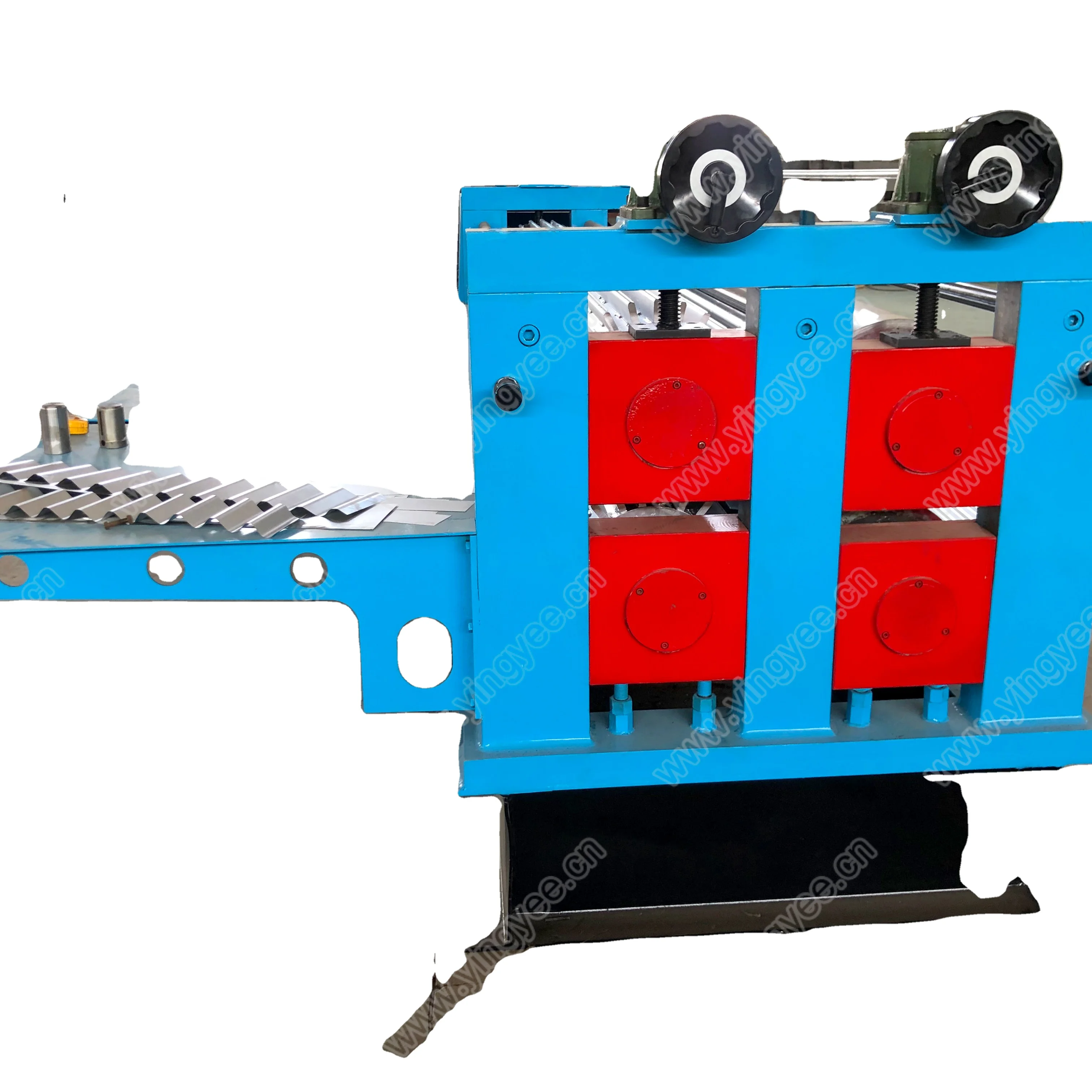

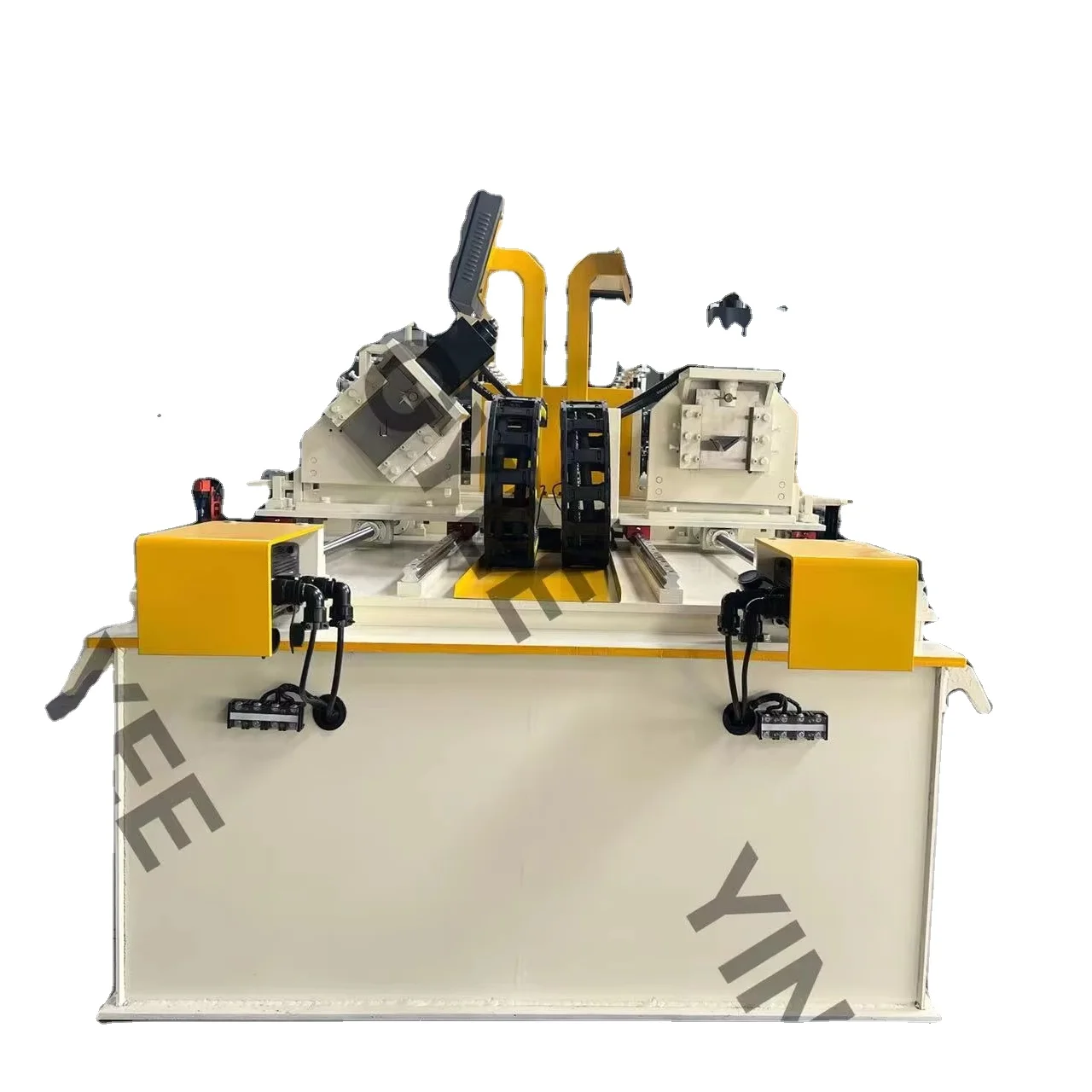

Special machinery rolls the steel strips back very tightly as a spiral. After rolling the strips into this spiral, they are kept in place either by wire winding or strapping. After installation, the coil is buttered up and prepared to get shipped out of where it's made off to other factories for making more products.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY