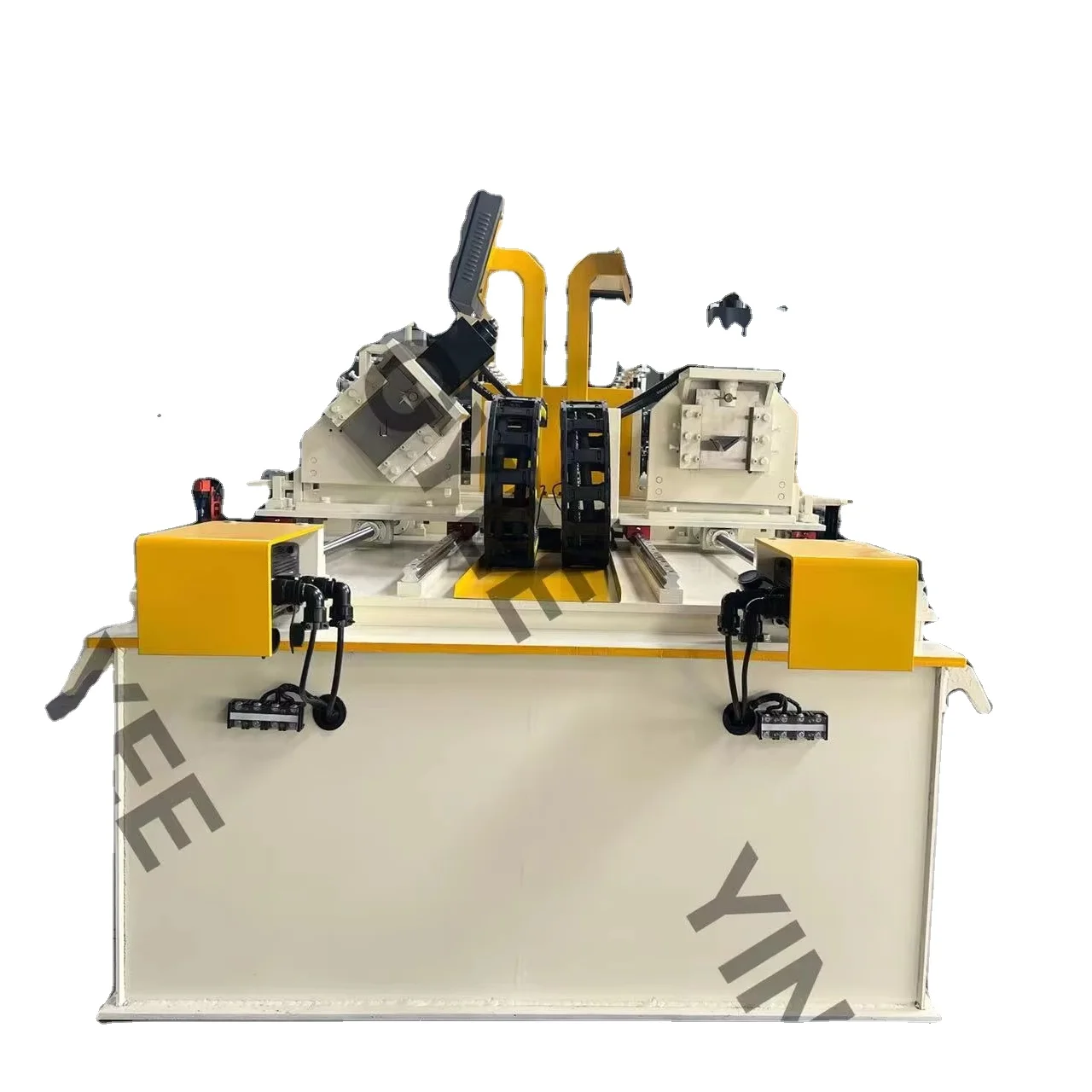

A U channel roll forming machine is a good choice, for many reasons. They can produce vast quantities of U-shaped channels at high speeds, which is one big reason. This is crucial in industries like construction and manufacturing, where they produce shafts that have the same size and shape. Building houses, cars and other products require consistency so these machines 100% guarantees that each channel is exactly the same.

The other part itself is that these machines are major cost savings over time for the businesses using them. They are very low maintenance, in fact they do not require much care at all This is in aid of reducing costs as businesses will have less machinery to repair. Moreover, U channel roll forming machines can last a considerable time which means you will be able to enjoy such cutting services for many years before they are worn down and need replacement. The long life of this product makes it a great value for any business that is trying to save money. In addition, these machines can be set up for various shapes. Manufacturers are therefore able to configure the machine infrastructure to create these specialized U-channels for their products, making them highly adaptable.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY