Hi kids! Ever wondered what those shiny roofs made from sheets of metal are called? What are those shiny sheets used for?Roofing sheets! However, they are quite essential as well, as they shield buildings from rain, snow and the sun. The best part is, these roofing sheets are manufactured through special machines, which can produce thousands of sheets in one go. My company YINGYEE specializes in manufacturing high-strength and high-performance roofing sheets, so you can rest assured that you are sitting under our products.

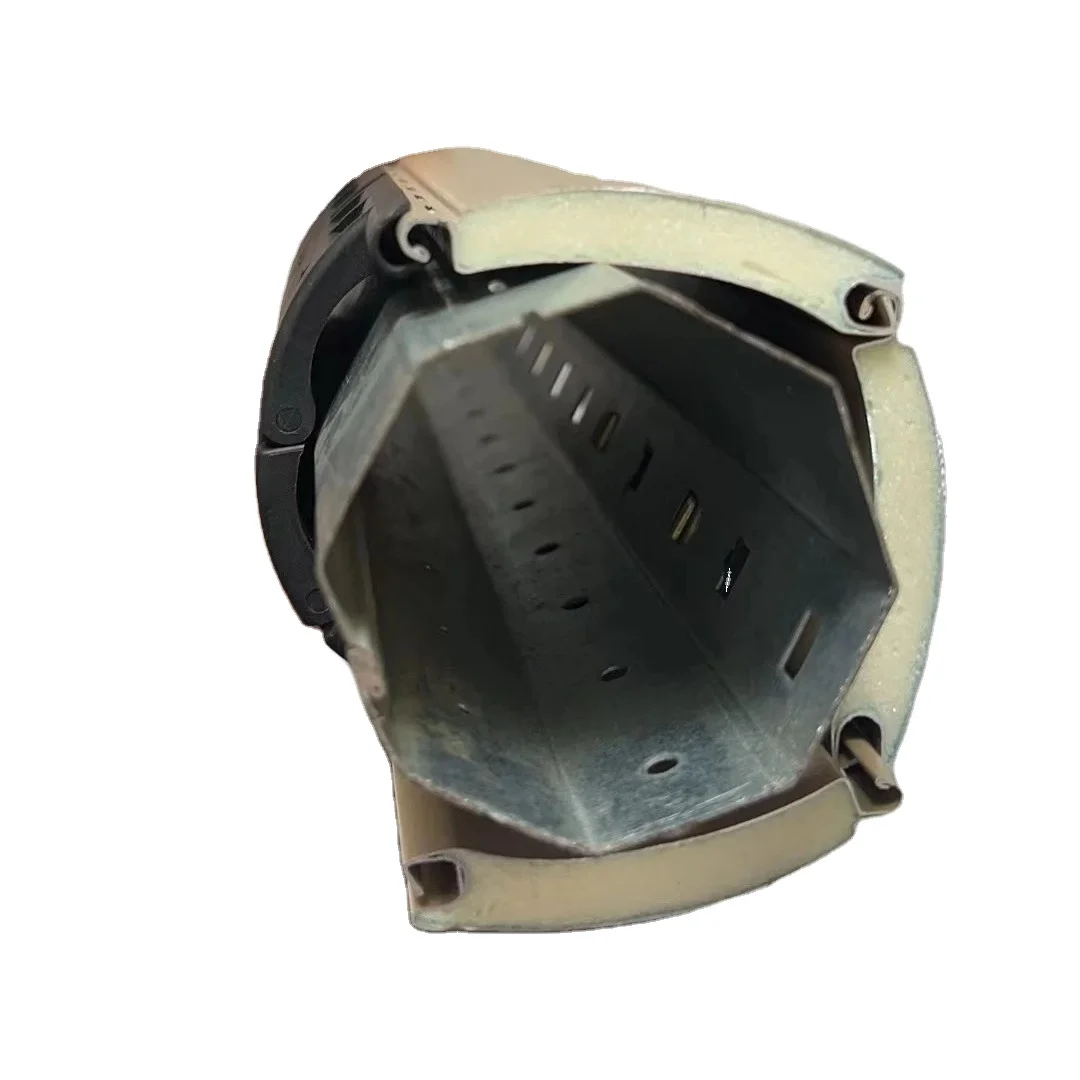

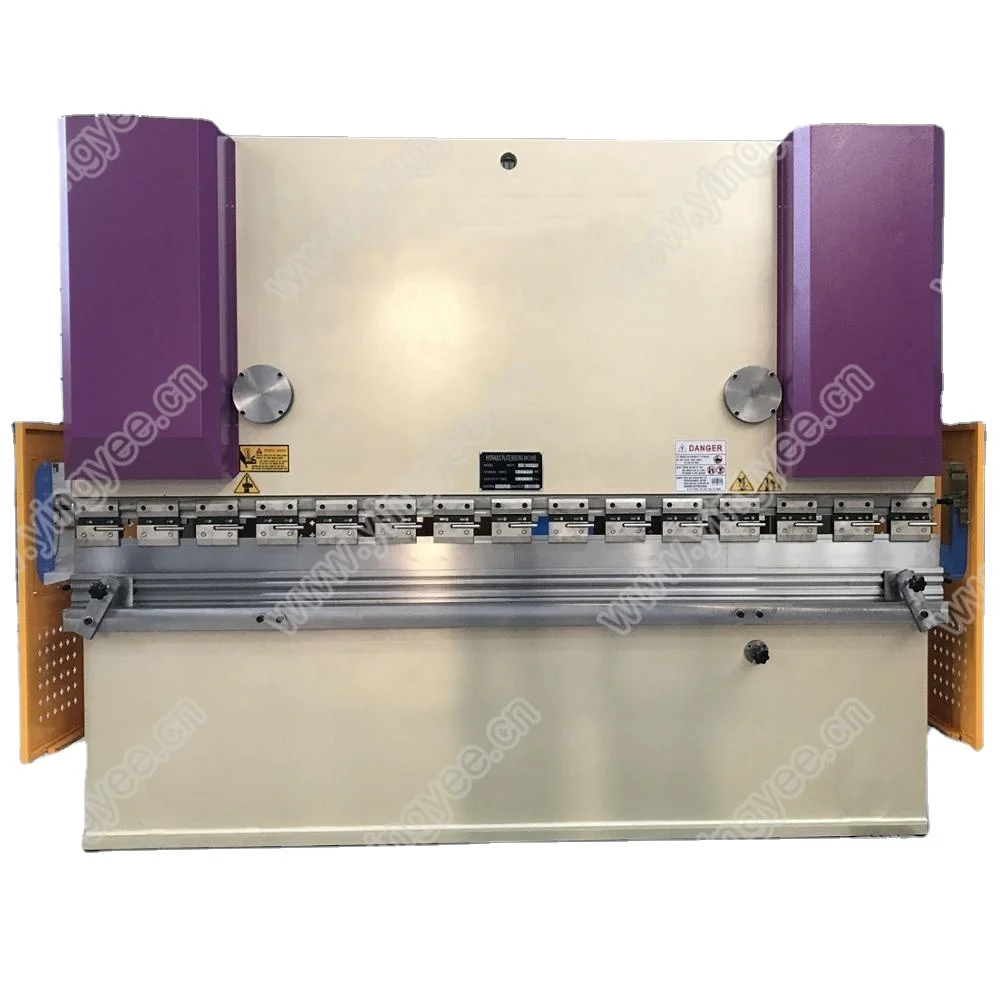

Our machines make these metal sheets; due to our machines, we get it using it without quality loss at a faster rate. We use it technology available today, which greatly assists us in doing so. These machines are manned by skilled workers to ensure that everything is seamless. They ensure that the machines run properly and the roofing sheets are shaped correctly. A lot of different parts make up the machines, which function together like a big team to produce the sheets that go on roofs.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY