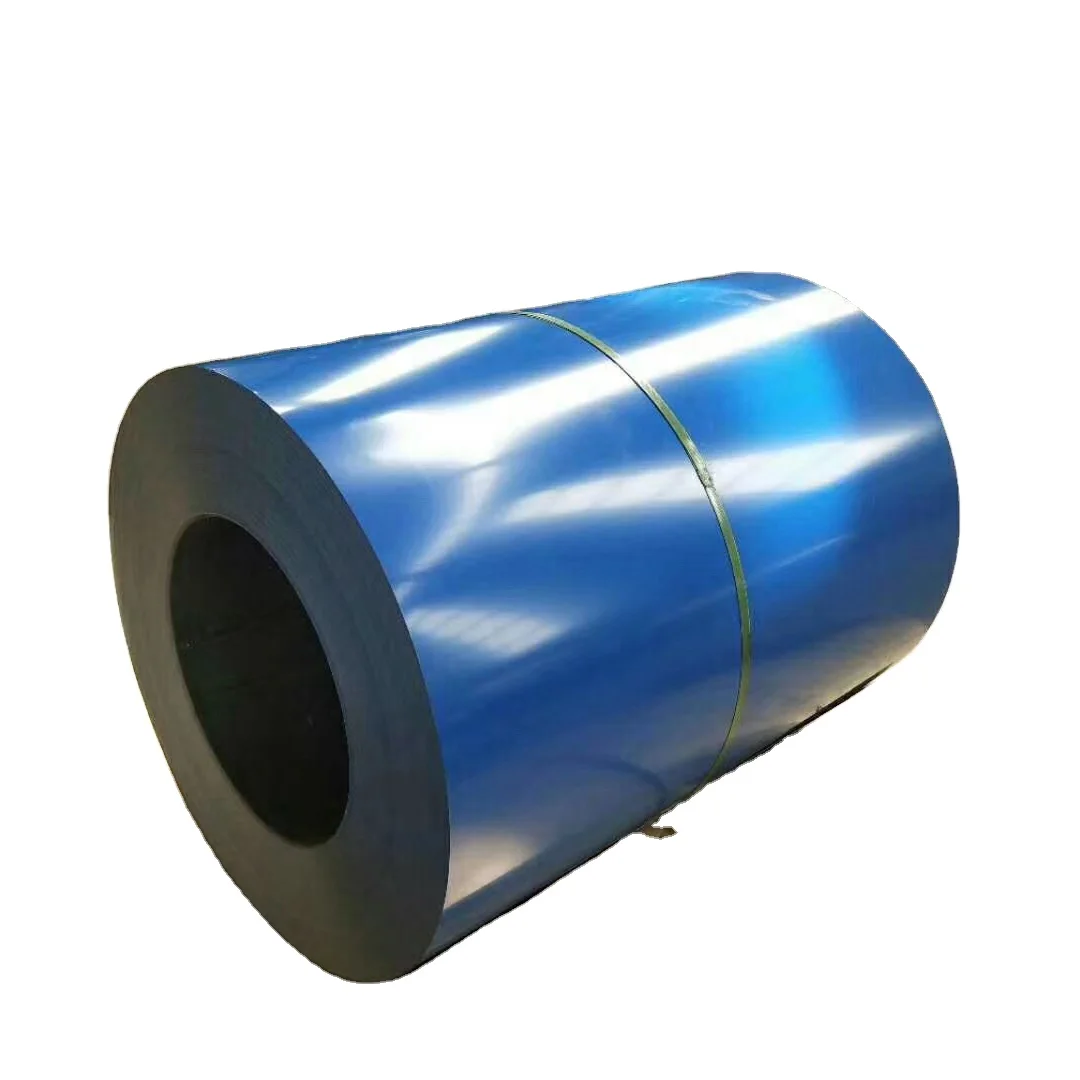

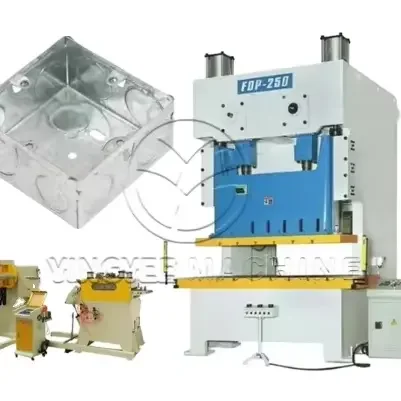

Have you ever wondered how the large rolls of steel we see at the construction sites are being cut into smaller, more manageable sizes? The answer is a special machine called a steel coil*! YINGYEE is the owner of a coil slitter machine, which can help you cut steel easily, save a lot of cost, and improve work efficiency!

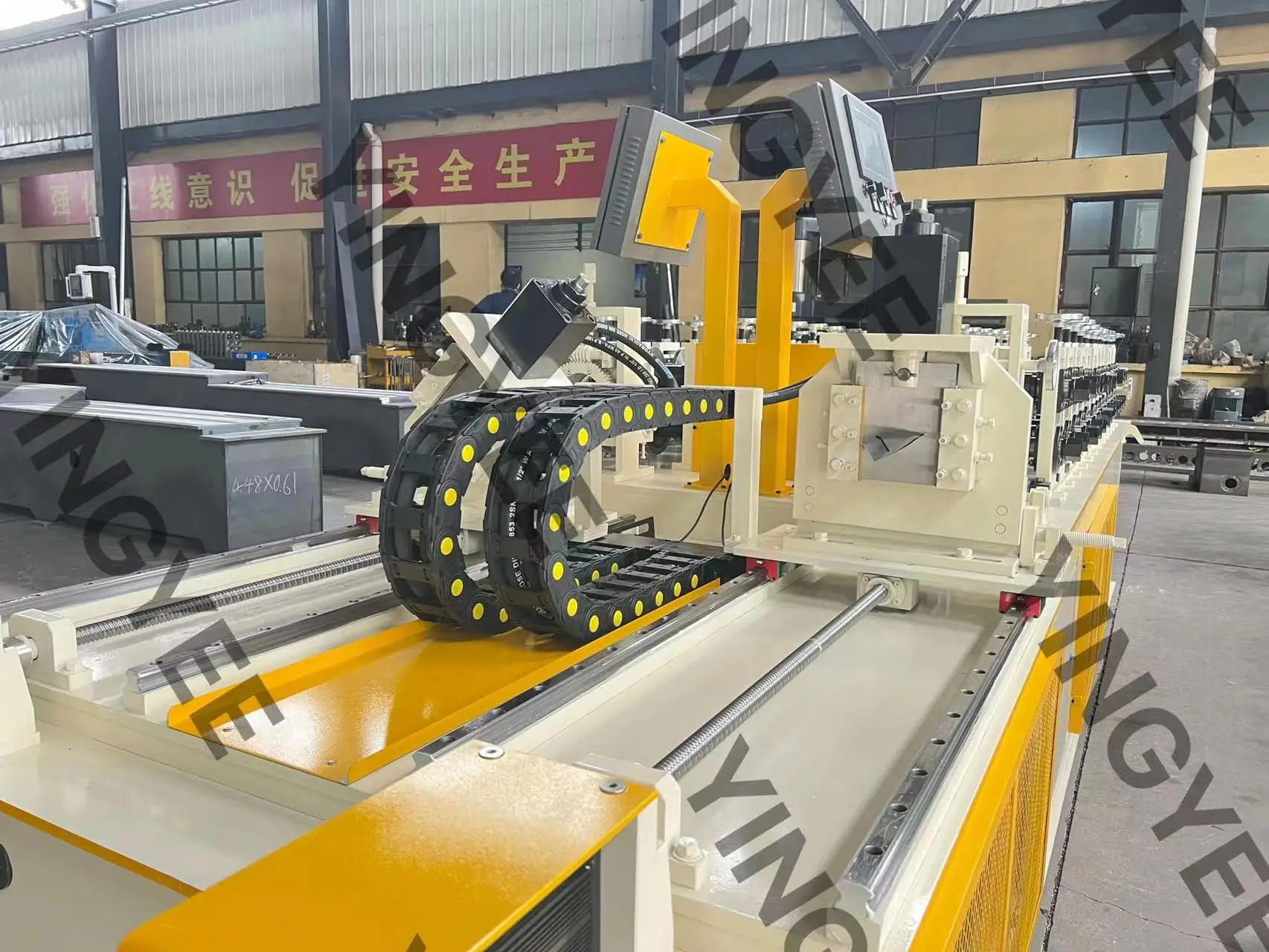

Cutting through steel coils — and thick ones at that — is easy with YINGYEE’s coil slitter. That is because it has deceptively sharp blades. (Not like you were hoping it was going to tear, because these blades are designed to cut accurately and cleanly, meaning you can get the exact right size of coils every time without a fuss.) It does everything from wide to narrow!

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY