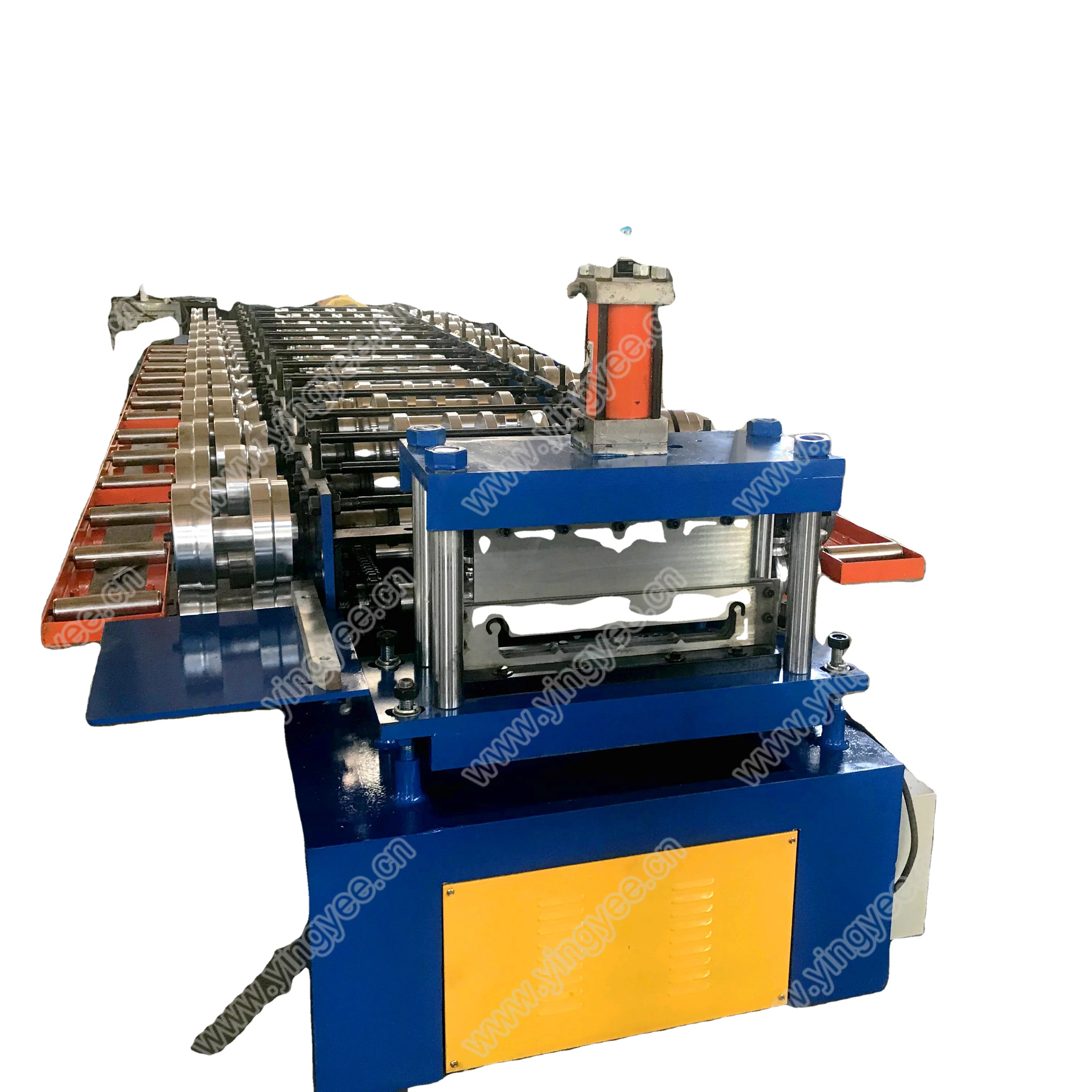

Its special machine is known as a Standing Seam Machine. It makes the construction process easier and quicker. But what’s this machine, and how does it function? This article reviews the multiple advantages of standing seam panel machine, how this machine is revolutionizing the construction industry, how it operates, what to consider when buying one, and the reason why the use of this machine is a great idea.

A major advantage of the standing seam panel machine is how quickly it operates. Because the machine can make the panels very quickly, the construction jobs can be done much faster. This is positive for builders, letting them complete a project and go to the next one. Also, because the panels are manufactured on construction sites there is much less waste. That means less waste material and less transport needed to drive panels from site to site.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY