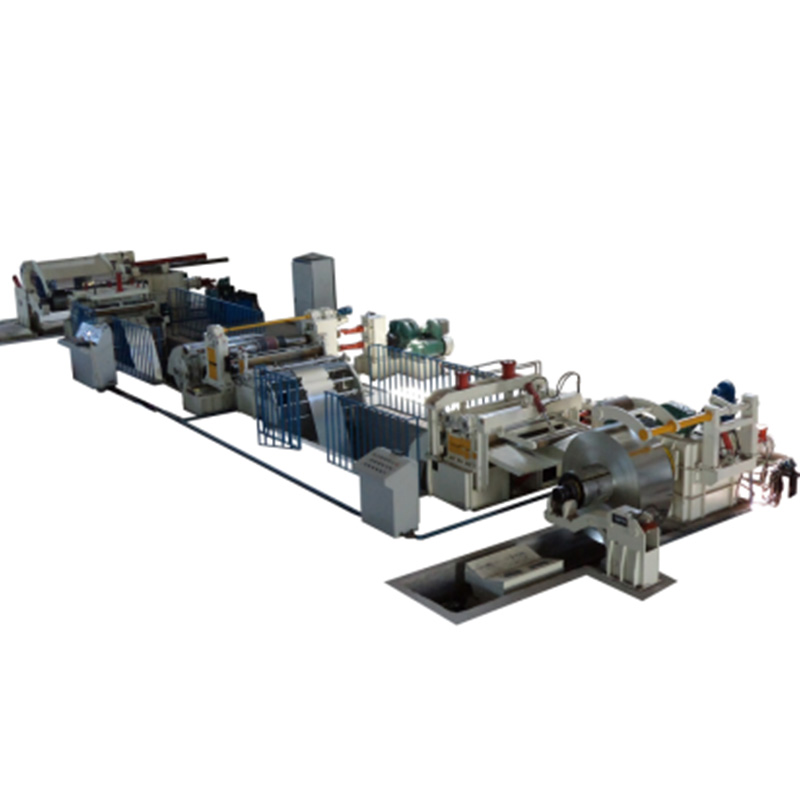

The Good Thing About Metal Roofs for Your House Metal roofs can keep your house safe, dry and protected during bad weather. They are extremely durable and can last for a very long time, which is why many individuals prefer them for his or her homes. But, have you ever thought of how we fabricate these metal roofs? So the answer is we fabricate it with the help of a metal roof roll forming machine! Let’s take a look at how these machines work and why they are essential for making roofs.

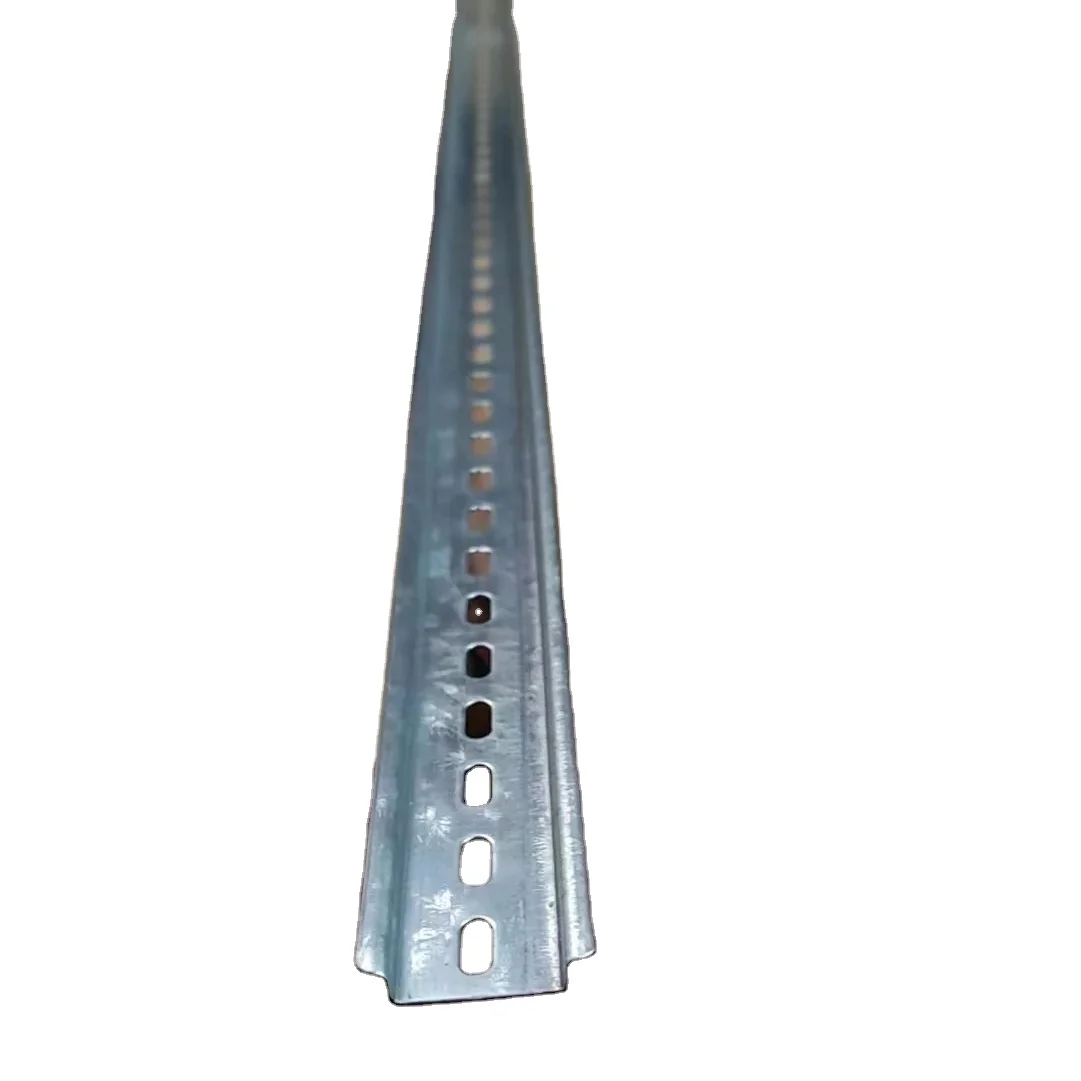

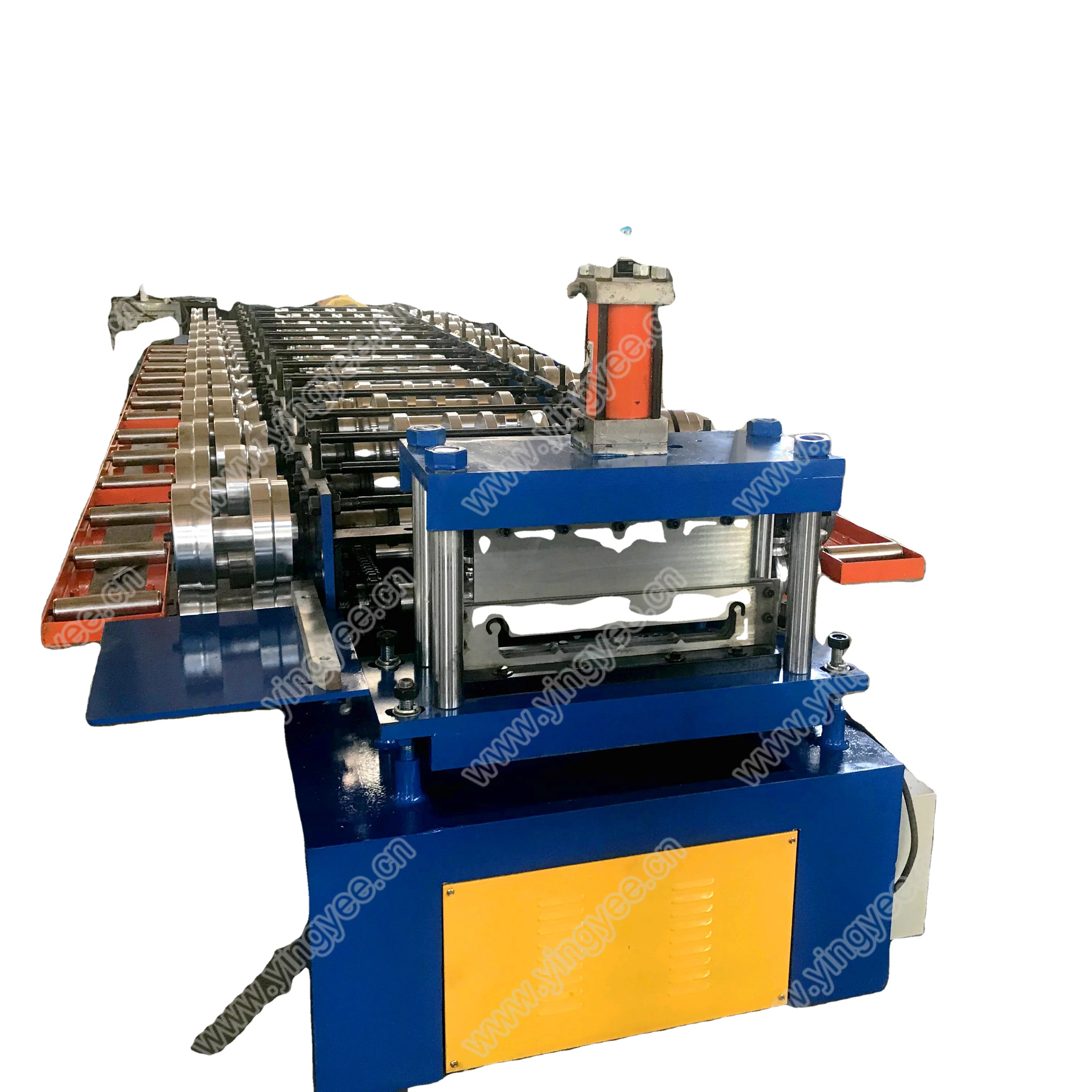

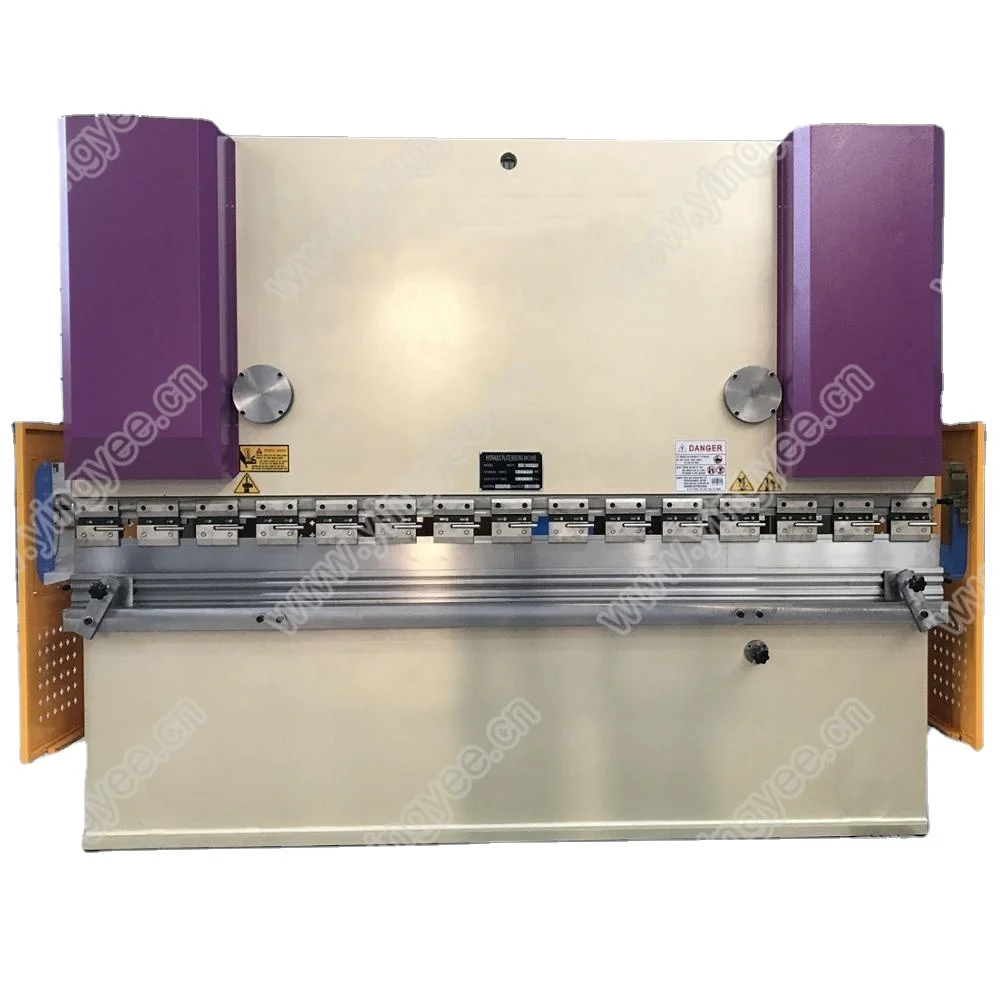

We begin with a flat sheet of metal, and the origami in metal creates a profile that becomes a metal roof. Then this flat sheet of metal is pushed into the YINGYEE metal roof making machine. Inside this machine, the metal takes on an incredible metamorphosis into a roof panel. It also cuts the panel to the correct size and the correct shape, and if anyholes are needed for screws or nails, the machine punches those holes as well. Finally we have a just made metal roof panel that is ready to go on your home. All of this matters because it ensures that each panel is made correctly.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY