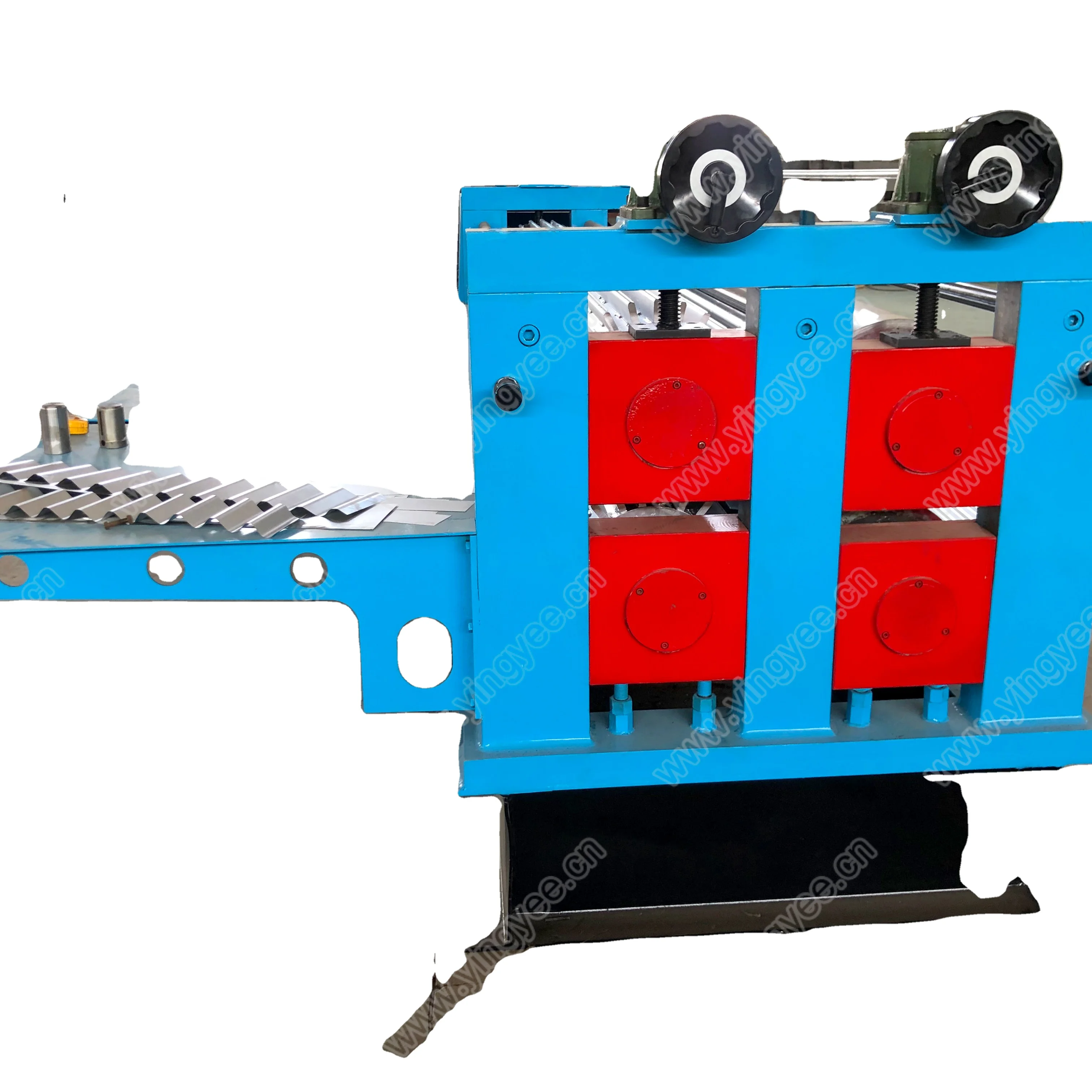

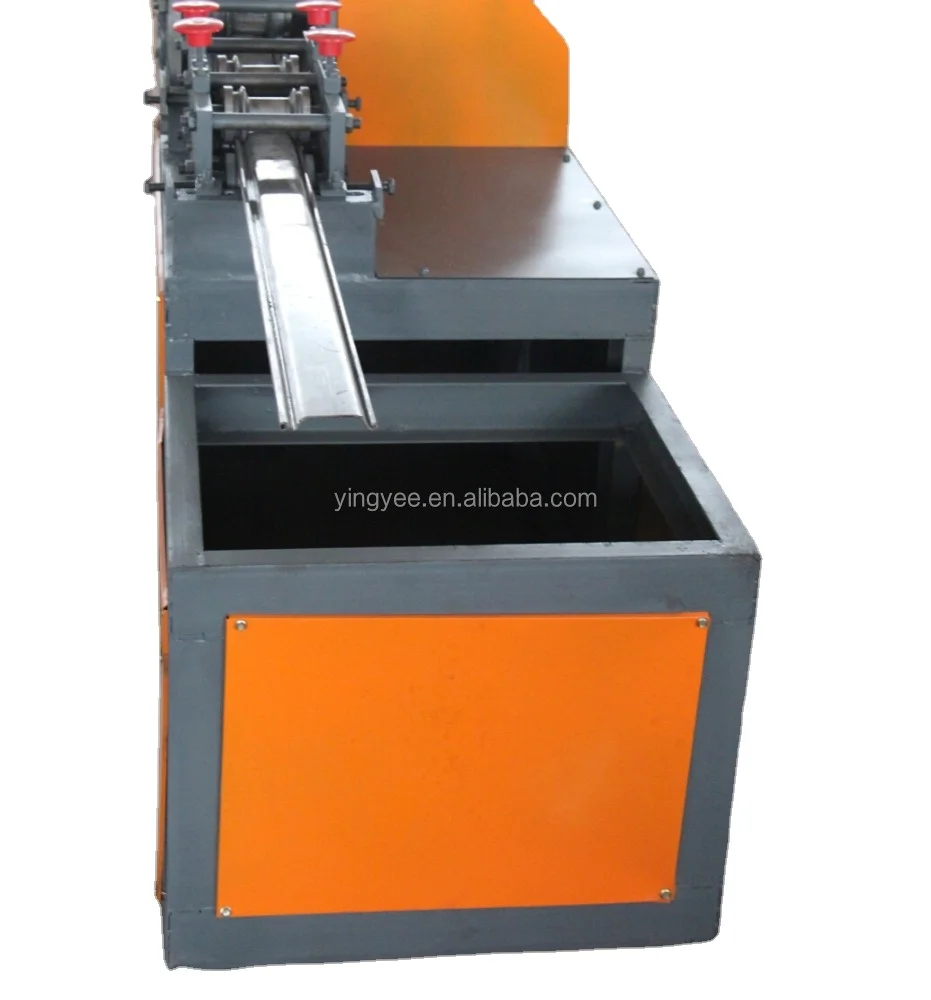

YINGYEE is a professional manufacturer machines of corrugated metal. But what is corrugated metal? Corrugated metal is steel that has a wavy form. And this wavy design is not only for aesthetics, it serves to strengthen the metal. YINGYEE’s machines feed flat sheets of metal and transform them into these wavy sheets. They obtain this by forcing the flat metal through rollers that have bumps or ridges on them. These bumps are used to form the metal into a "wave" pattern.

There are a wide range of industries that use these corrugated roll forming machines. For instance, in the building trade, plastic corrugated metal sheets are used to construct roofs and walls of buildings. Its wavy metal shape makes it resilient against rain and heavy winds. These corrugated metal sheets are used in the packaging industry to make durable boxes for shipping, holding the contents of the box in shipshape condition. It matters because you want your products to reach their destination unscathed. In the auto industry, for example, corrugated metal sheets are employed to form the hoods and trunk lids of cars. These parts must be both high-strength and low-weight, and corrugated metal fulfills those properties.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY