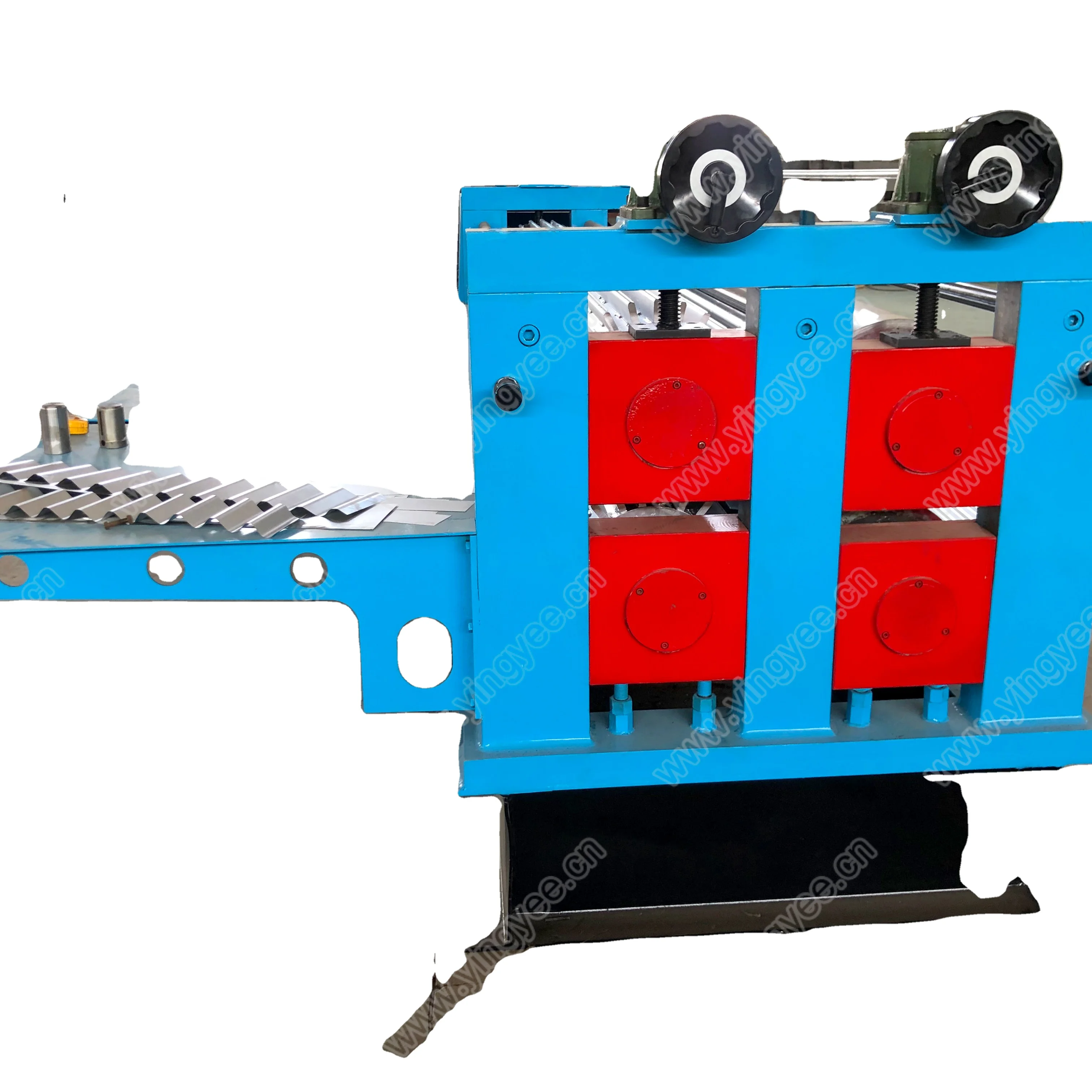

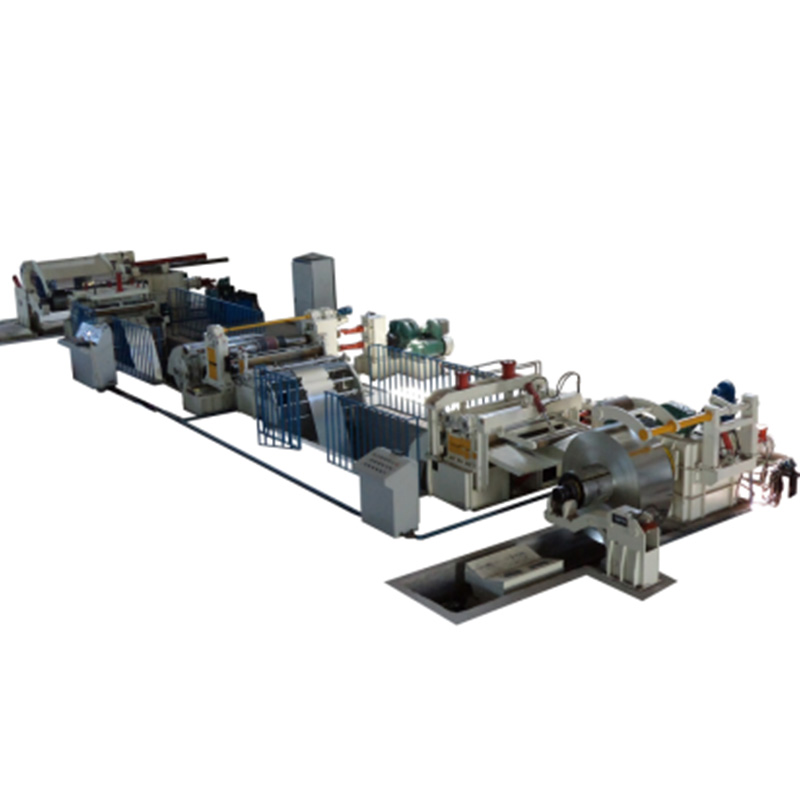

Get High-Quality Sheets with Double Layer Roofing Sheet Roll Forming Machine

The double layer of this machine is extremely helpful for increasing versatility. Which enables you to design roofing sheets with diversified and veritable modeling yet maintaining quality high. And there’s no need to compromise on durability for style. This machine can help you achieve plain sheets or sheet with intricate patterns!

One more advantage of a roll forming machine for sale is that it produces long-lasting, high-class sheets. These roofing sheets are made from very strong materials capable to stand in heavy weathers. They are made to withstand rust, corrosion and other damage. What this means is that after you install them, there is very little upkeep to maintain them!

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY