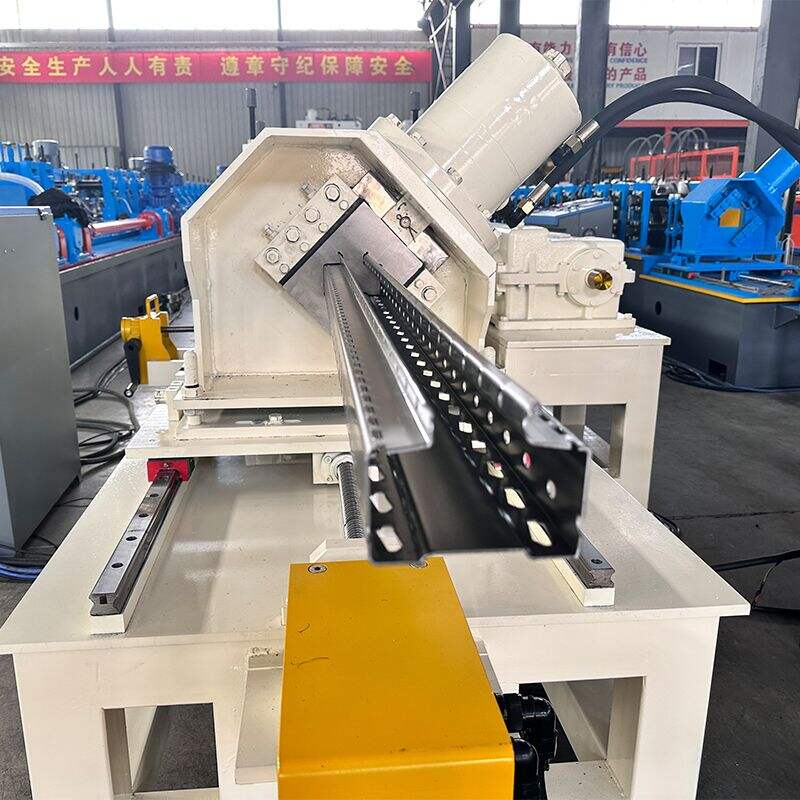

Rack Roll Forming Machine As the name indicates, the use for it is to create racks and shelves used for keeping things in an organized way. These are machines that can help streamline production and improve efficiency. Continue reading to examine how rack roll forming machine is able to help companies in a number of ways.

A rack roll forming machine is a piece of metalworking equipment that takes a flat piece of metal and forms it into a particular shape. This is process called roll forming, and it means companies can be quickly produce racks of different sizes and shapes that are accurately created. With the help of a rack roll forming machine, it is possible for the manufacturers to automate the rack making process itself, lessening the reliance on manpower and shortening the manufacturing time.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY