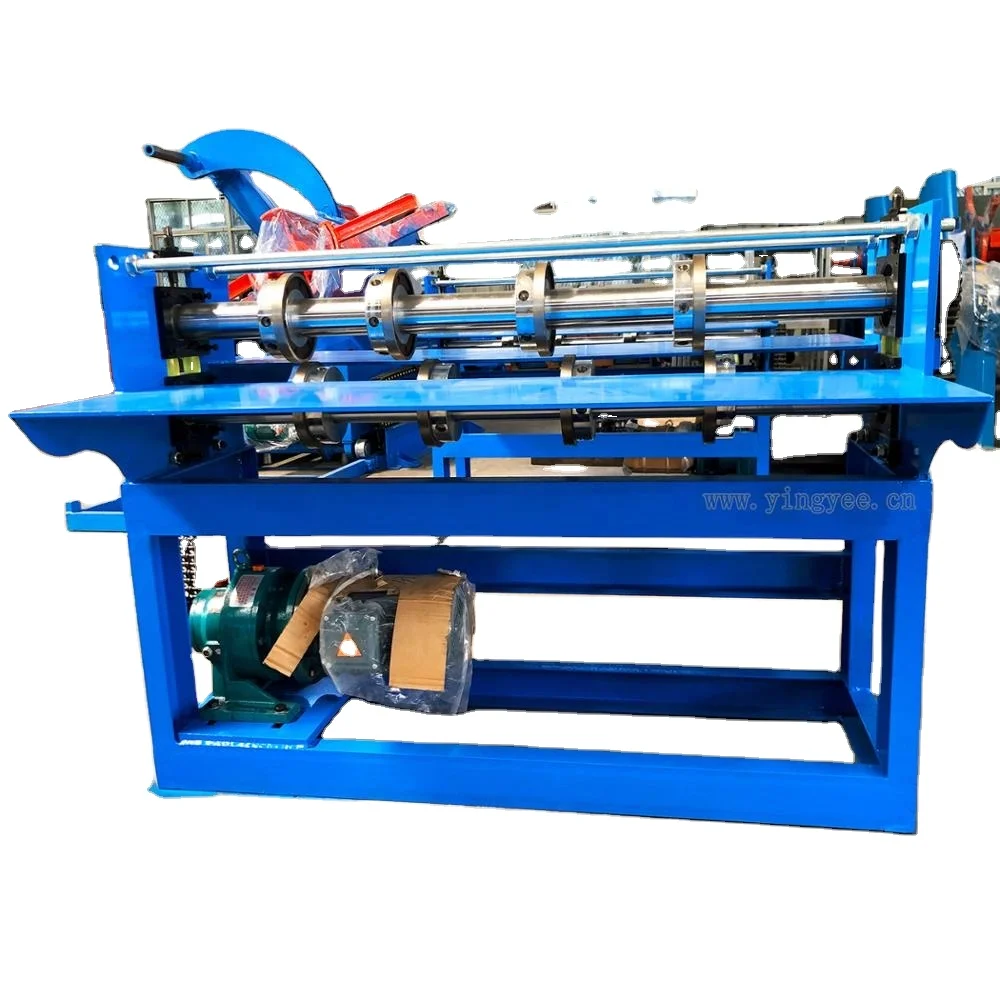

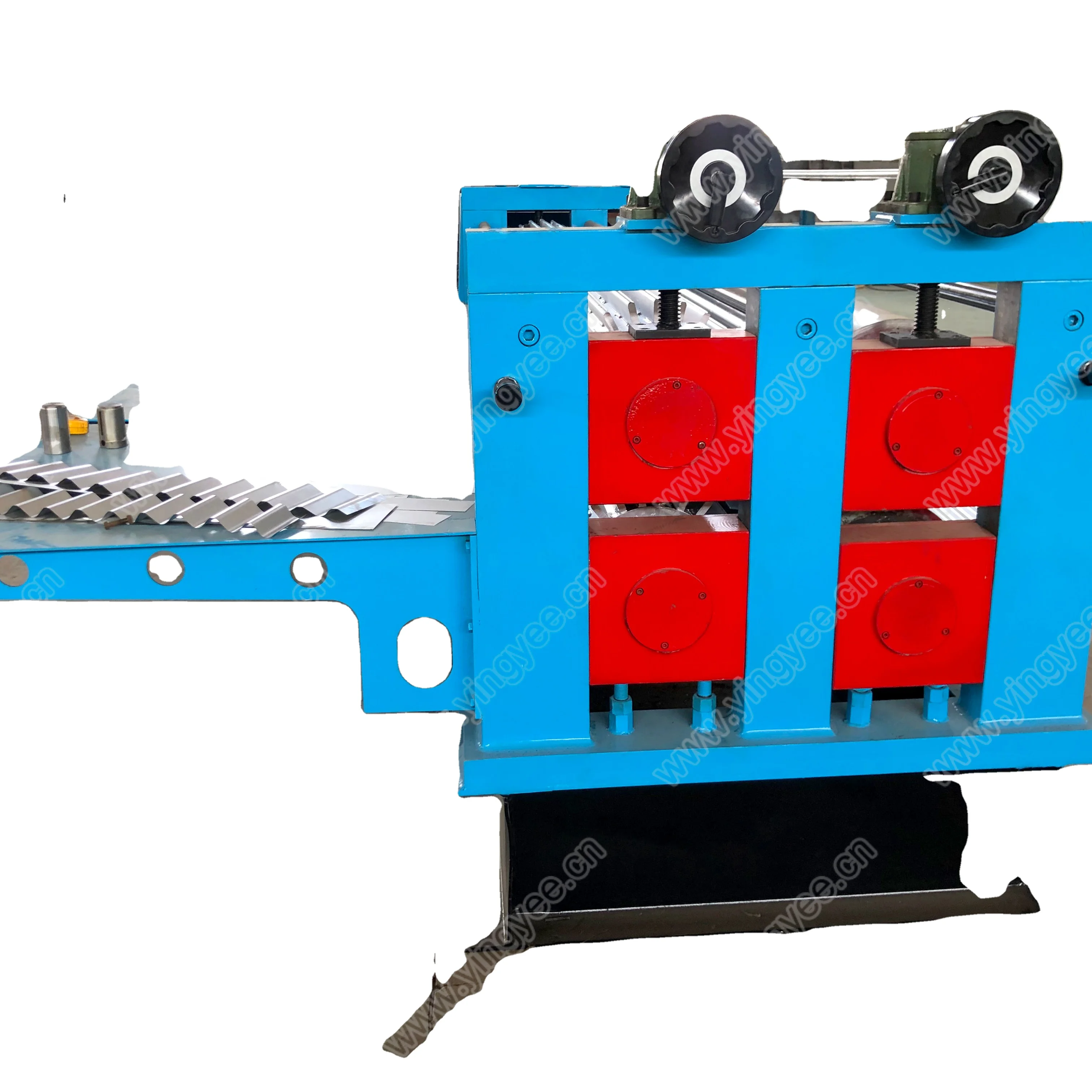

YINGYEE practice something called roll forming. You may be asking, "What is roll forming? Roll forming is a unique cold forming method used in metal design and fabrication. Think about if you had cookie dough and wanted to make it into fun shapes. You’d press a cookie cutter into the dough. In roll form, instead of dough, we use metal, our machine beats them, and they take special exposure for different things.

Roll forming is a great way to shape metal, the way there are many great things about roll forming. First, it works very fast. After setup, a roll forming machine can produce a high volume of formed metal parts without stopping for each individual piece. That means tons of metal can be processed in a very short period of time, which is especially beneficial when creating a large number of products.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY