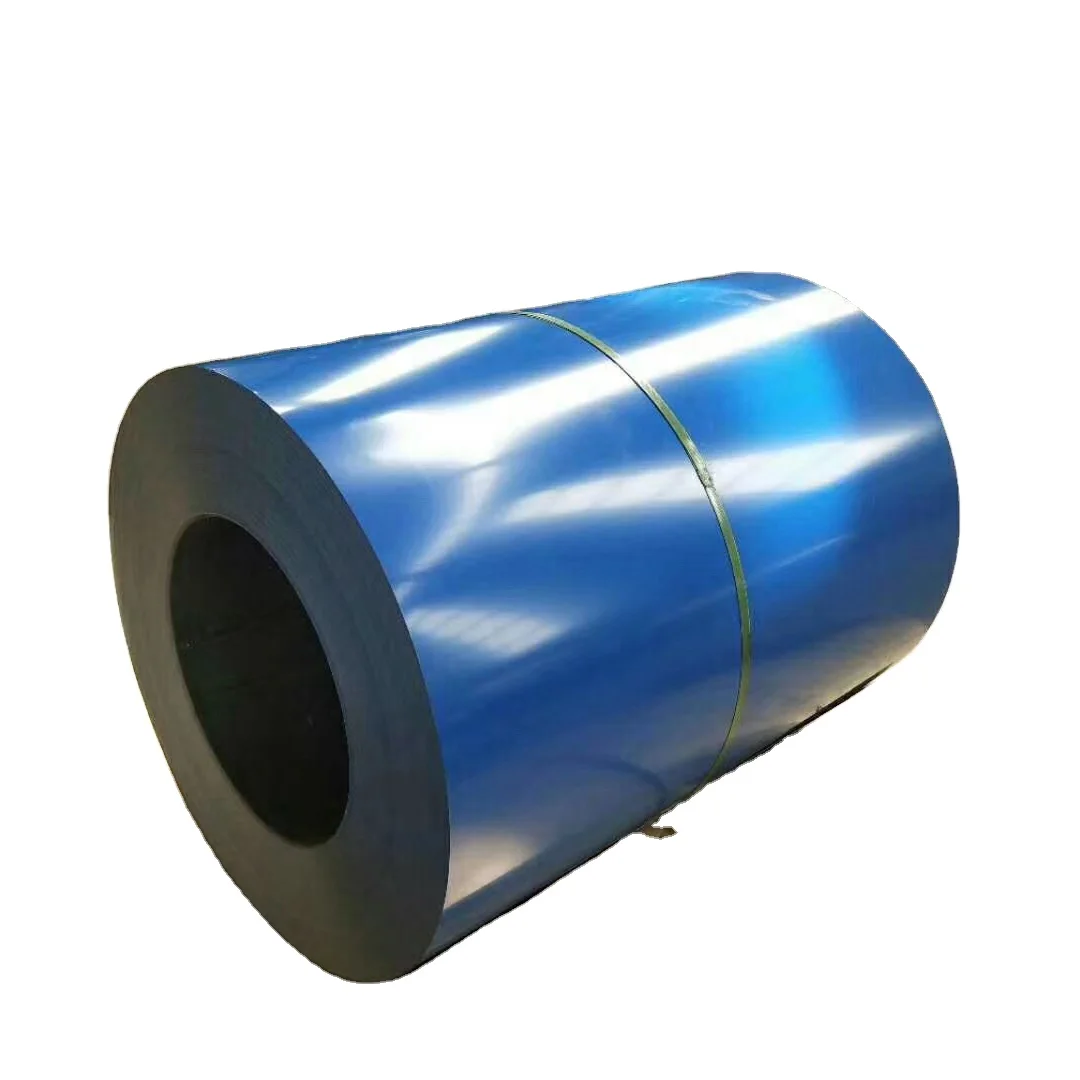

Unfortunately, little is known about the process of steel coil, which is a very important process that enables the production of many products that we encounter on a daily basis. They encompass cars, cans and even office furniture, among other products. Slitting—cutting large sheets of steel into smaller strips This allows manufacturers to use the steel in various applications. Let us discuss how you can make precise cuts, save time, work with different thicknesses of steel and have a simplification of the production and make your final goods have an enhanced appearance which you can achieve with steel coil slitting in this article.

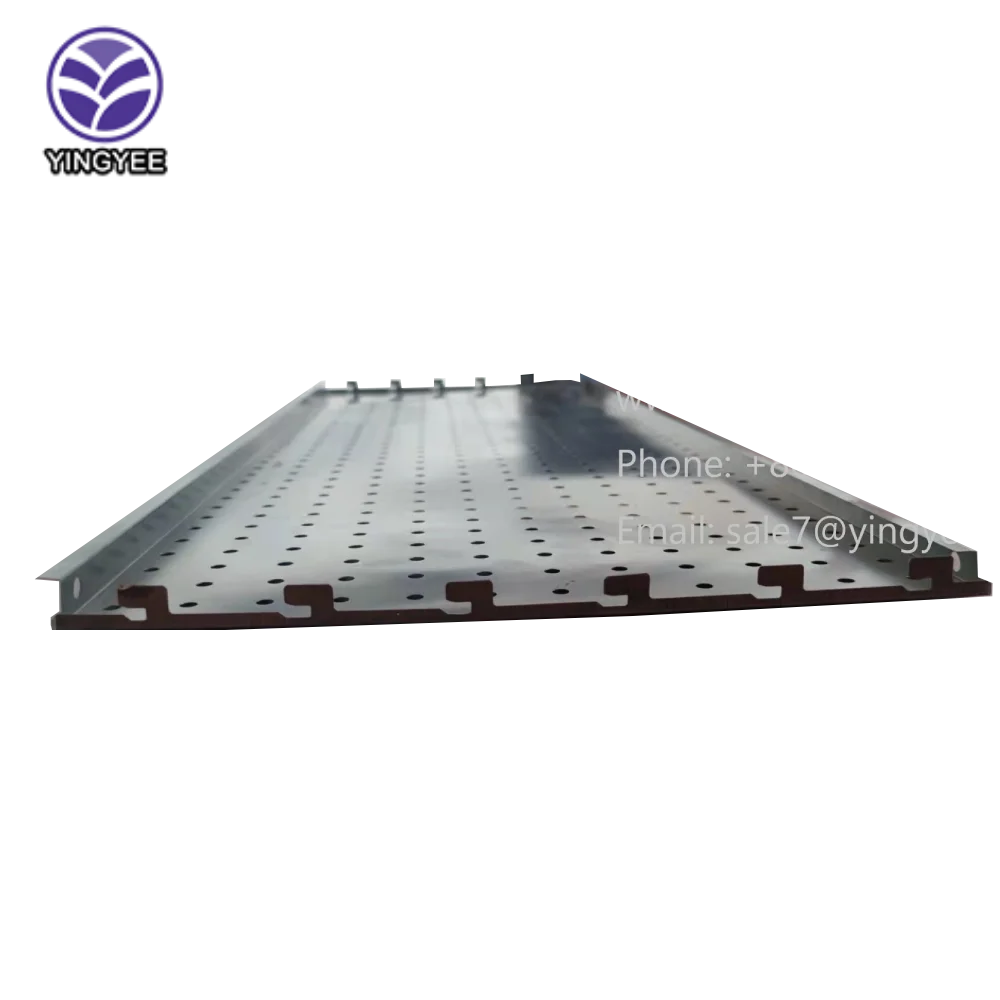

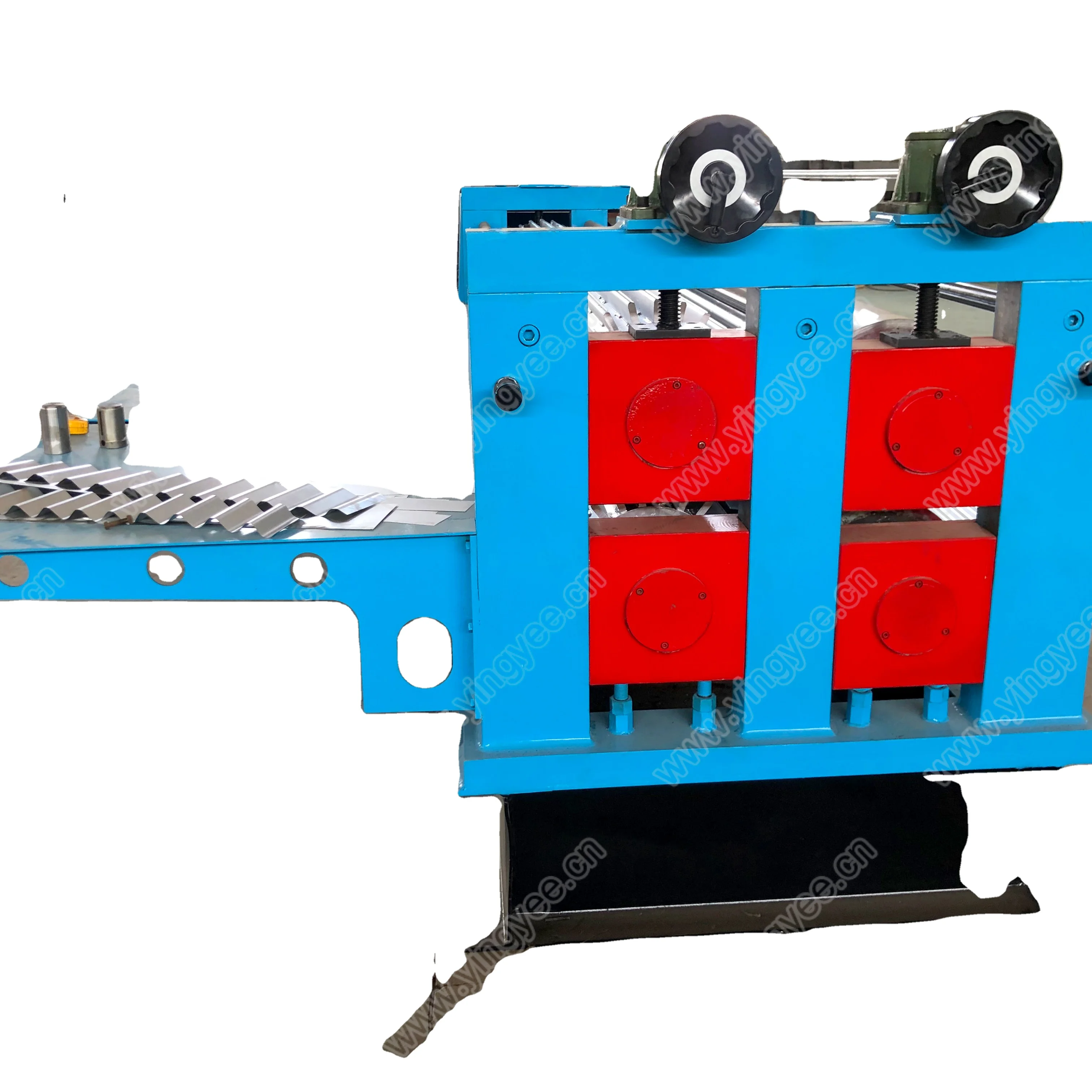

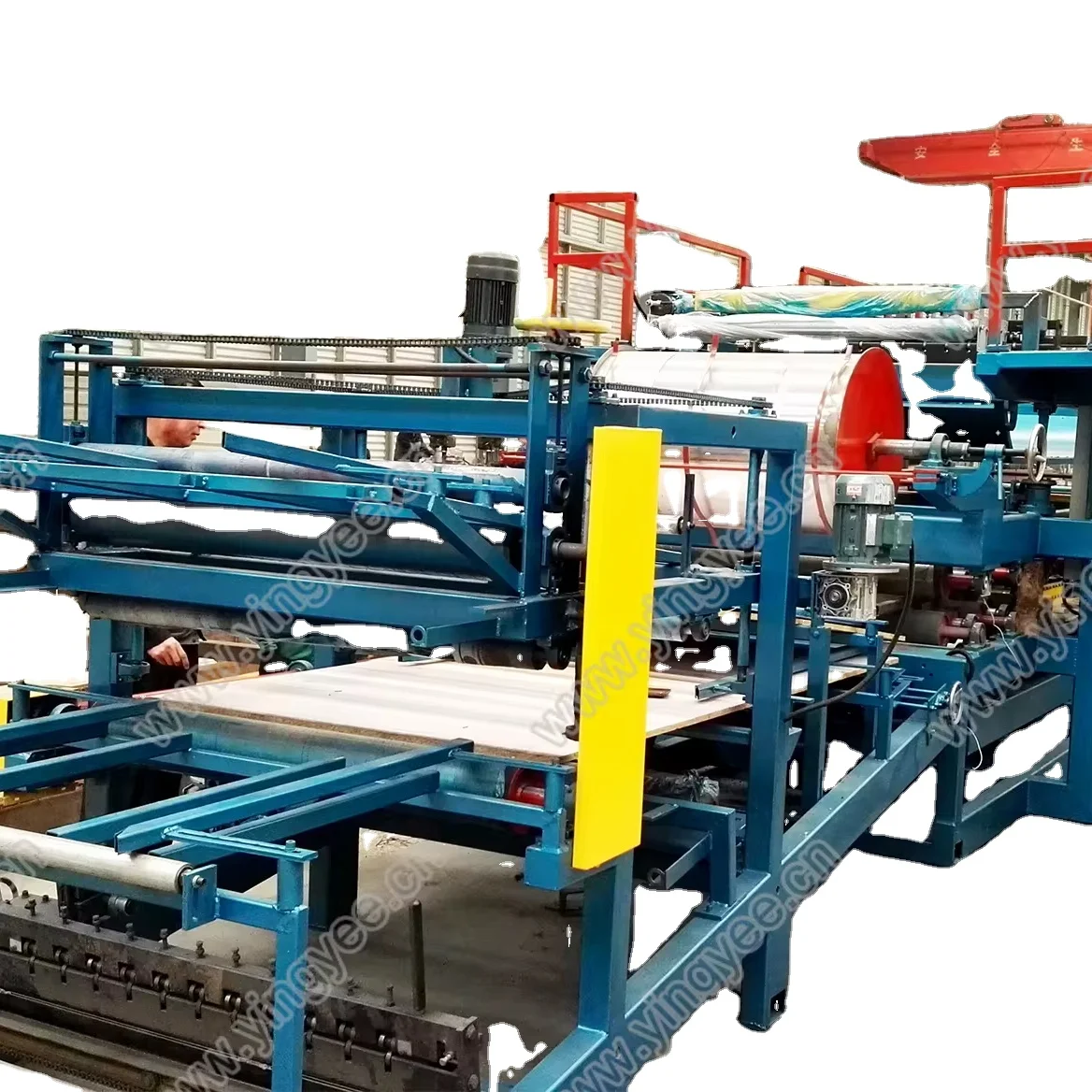

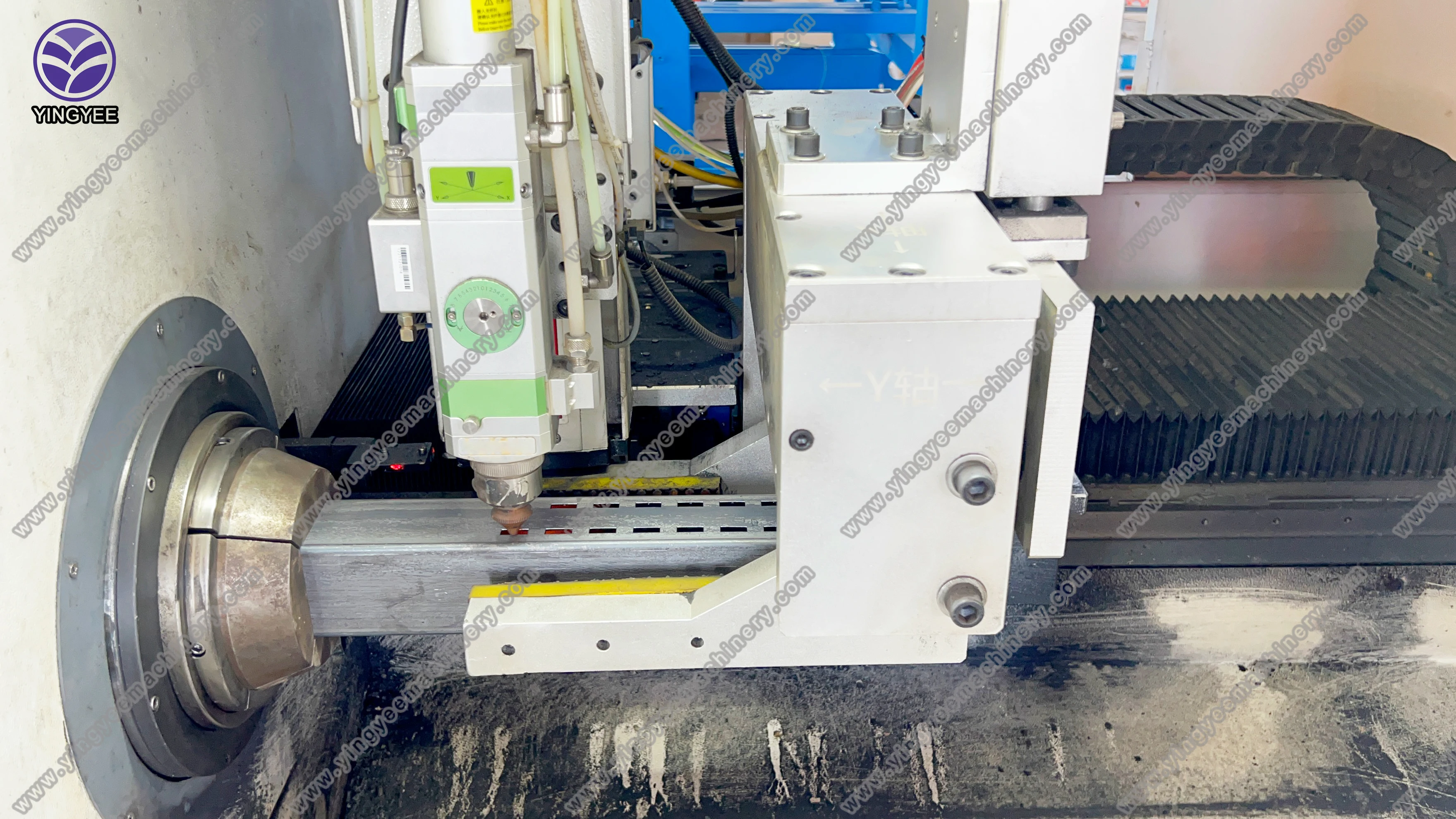

Steel is a material that requires cutting with accuracy and precision. Steel coils wake is done with a specific kind of machine purposely designed for a slitter purpose. These machines can accurately cut the sheets of steel into strips at different thicknesses. That means they can slice the strips so accurately that they are just a teeny-tiny bit off, a fraction of a millimeter. All the way to this level of fidelity so that the product is of high quality. If manufacturers have this precise cut, they can use it to manufacture better products that fit together nicely.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY