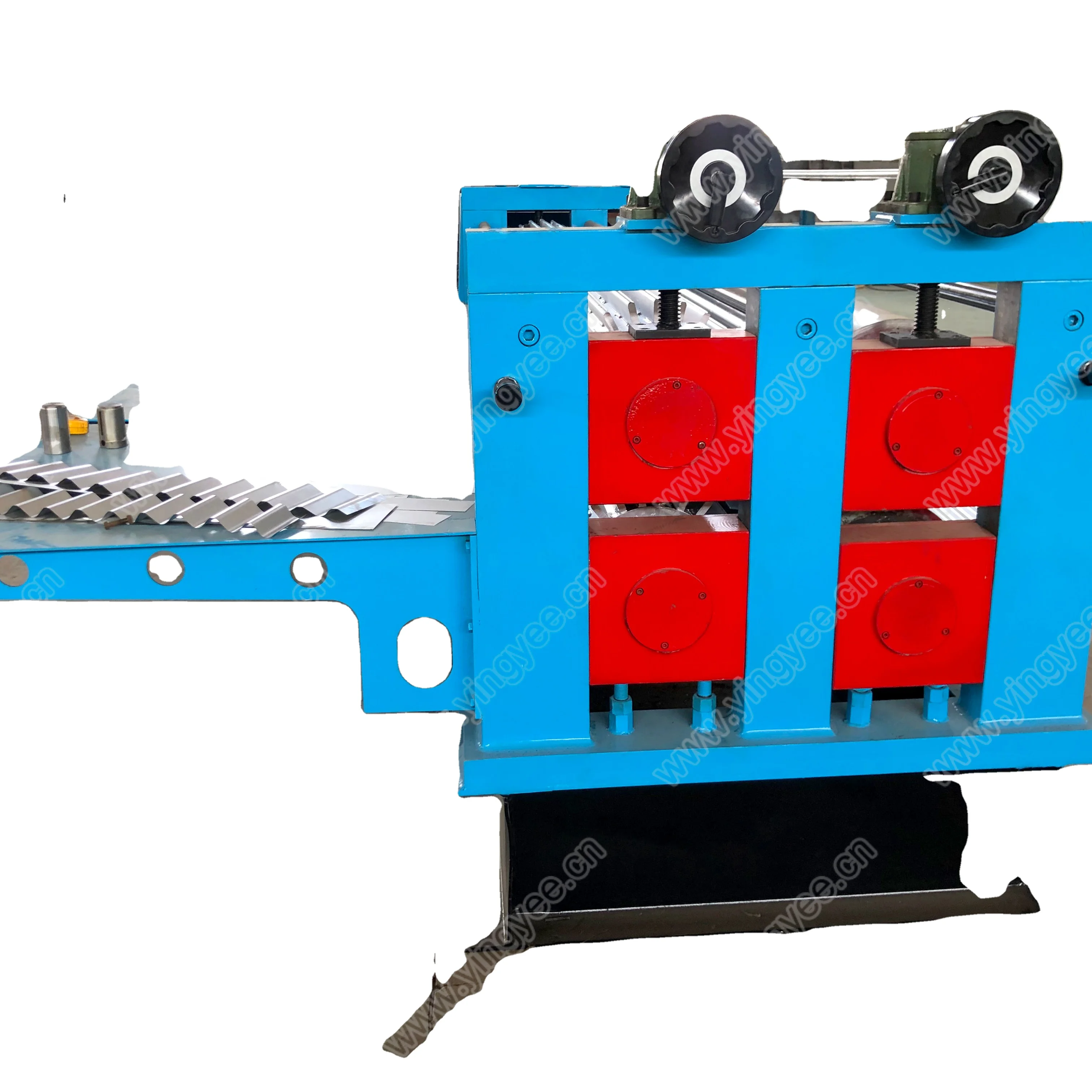

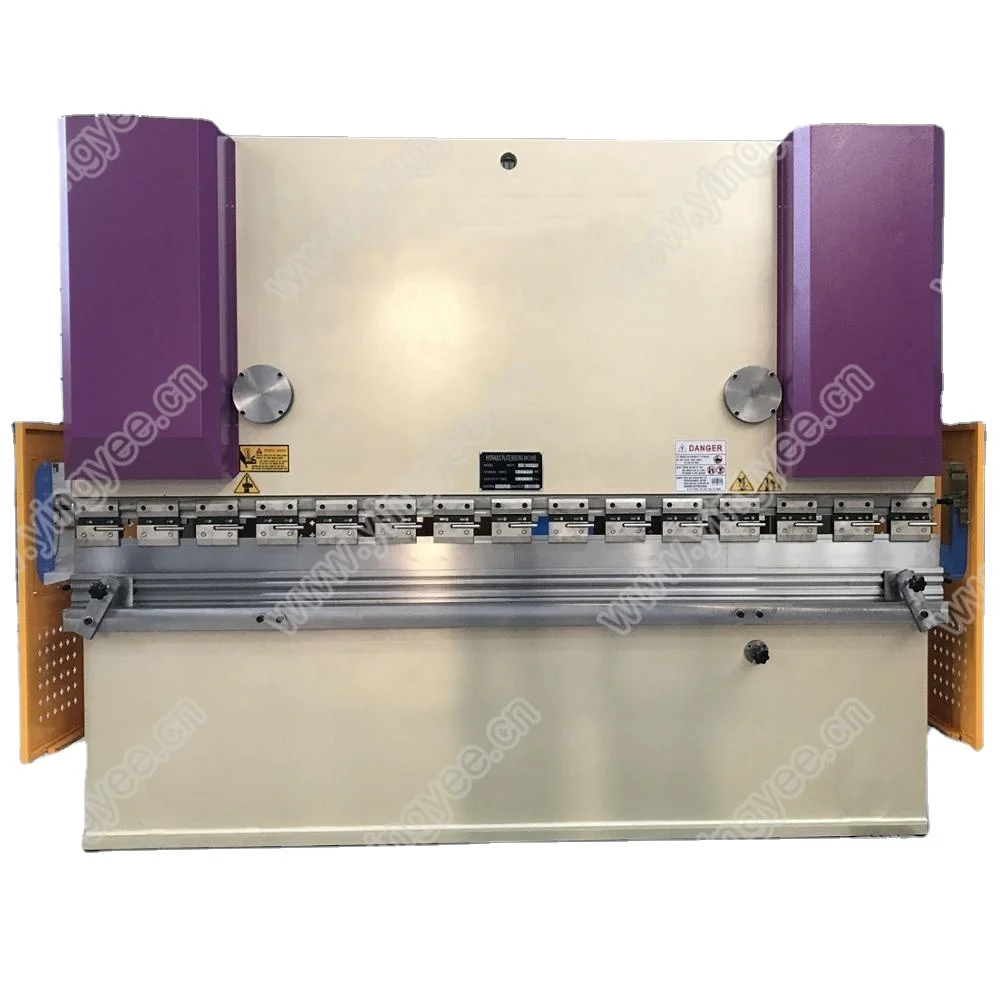

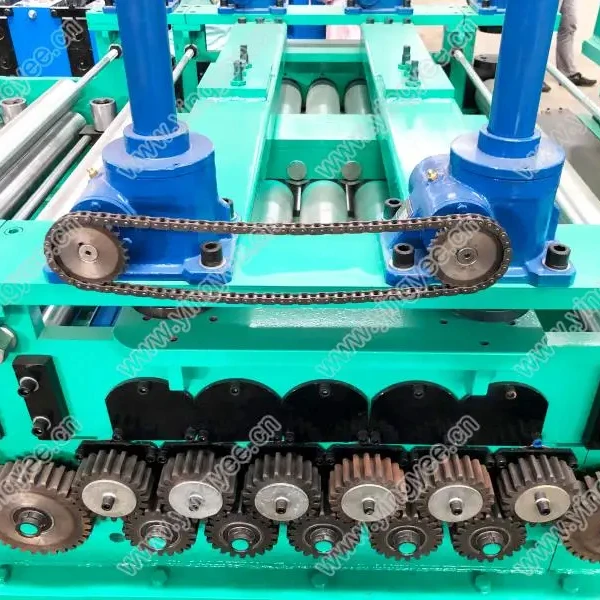

If you work with sheet metal in a factory, you understand that those sheets need to be straight. Something wrong with the sheets, such as intefering how to be styled and become awry, can cause these problems at any time. For instance, it’s when machines get stuck due to working with bent sheets, which slows down production. Uneven sheets create not just substandard cosmetic appearance, but also poor product performance. This is where YINGYEE Roof sheet roll forming machines come in handy!

A sheet straightening machine can ease several aspects of your work in couple of significant ways. The first is that it eliminates the need for workers to straighten the sheets by hand. It is a time-consuming and tedious process for the workers. Your output over time doesn’t improve, but using a machine, you can do more in a shorter amount of time, and with that you may not need nearly as much manpower. This way it will help you to save time and money and produce more.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY