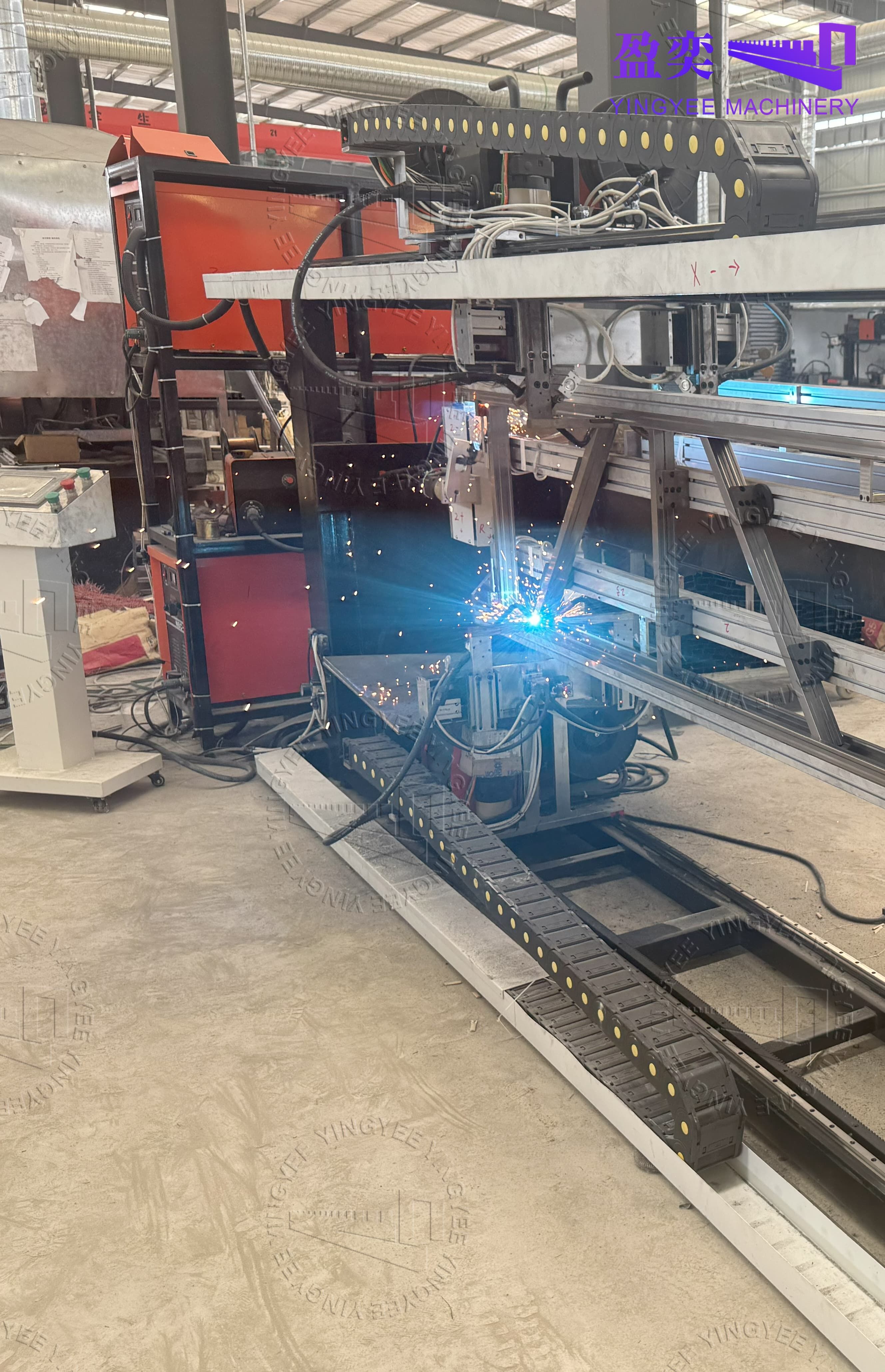

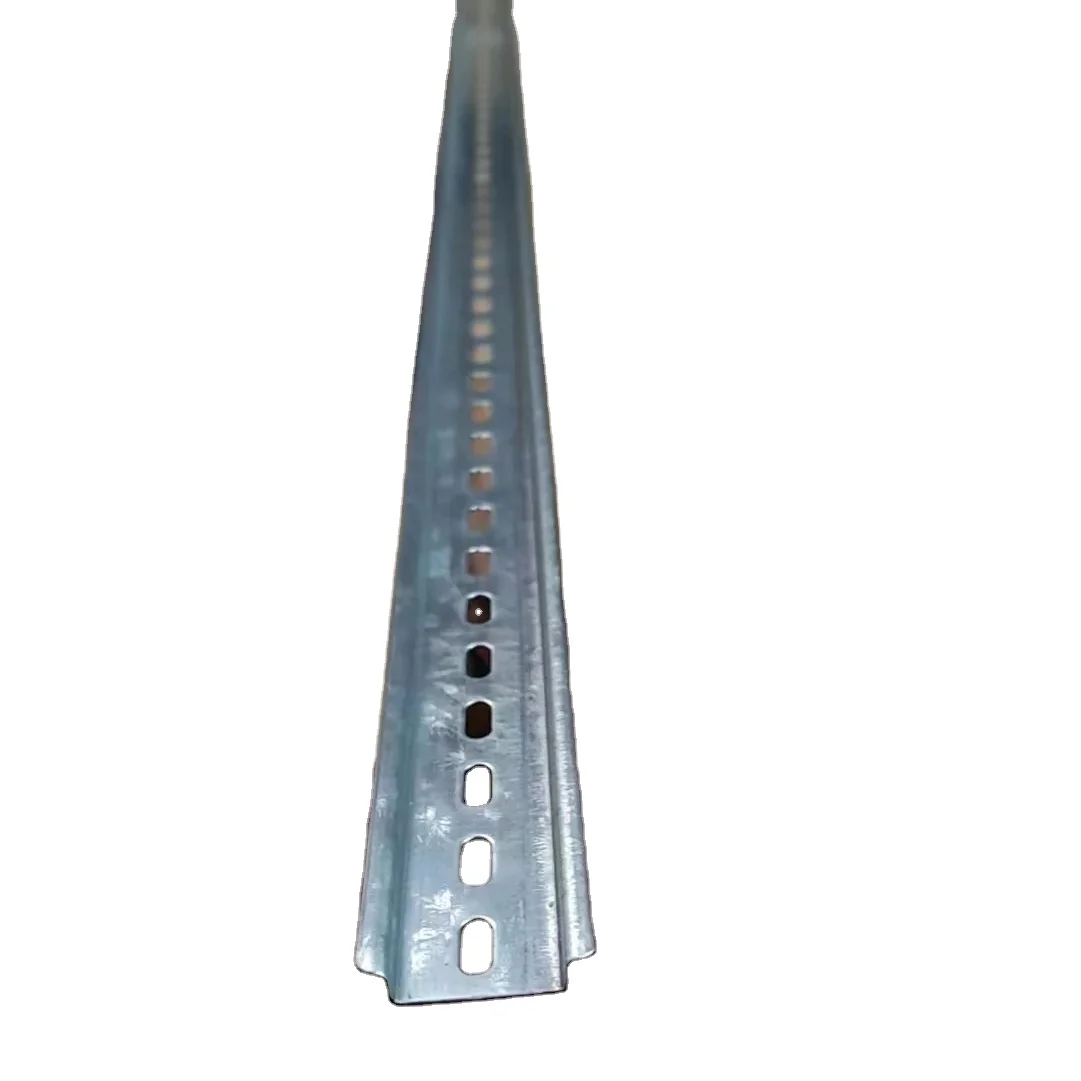

Guide Rail Roll Forming Machine

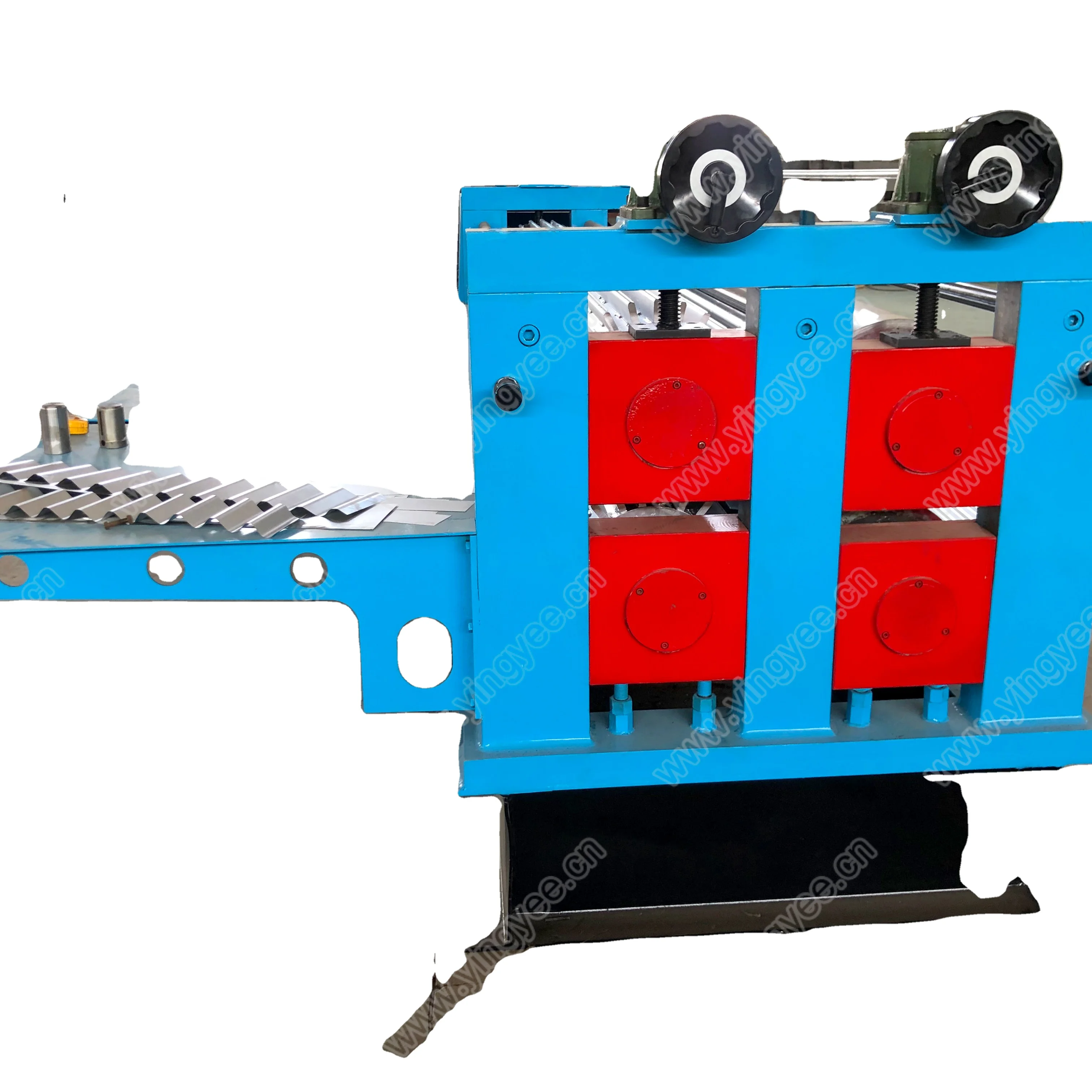

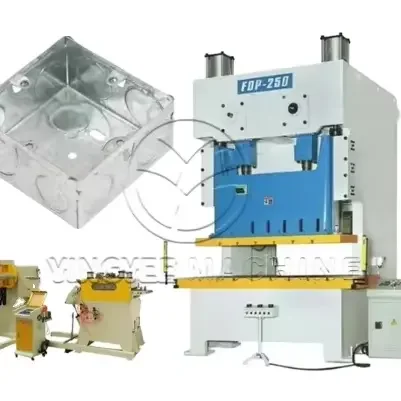

What is really cool about these machines, one of them at least but I am sure it will be more if the factory expands and we get into greater numbers: they can just work all day long. In simpler terms they may run until one batch of the necessary guide rails are complete. In this way they need no outage time and can produce many guide rails simultaneously. This saves time and energy for the people using these machines, making the manufacturing process a great deal more efficient.

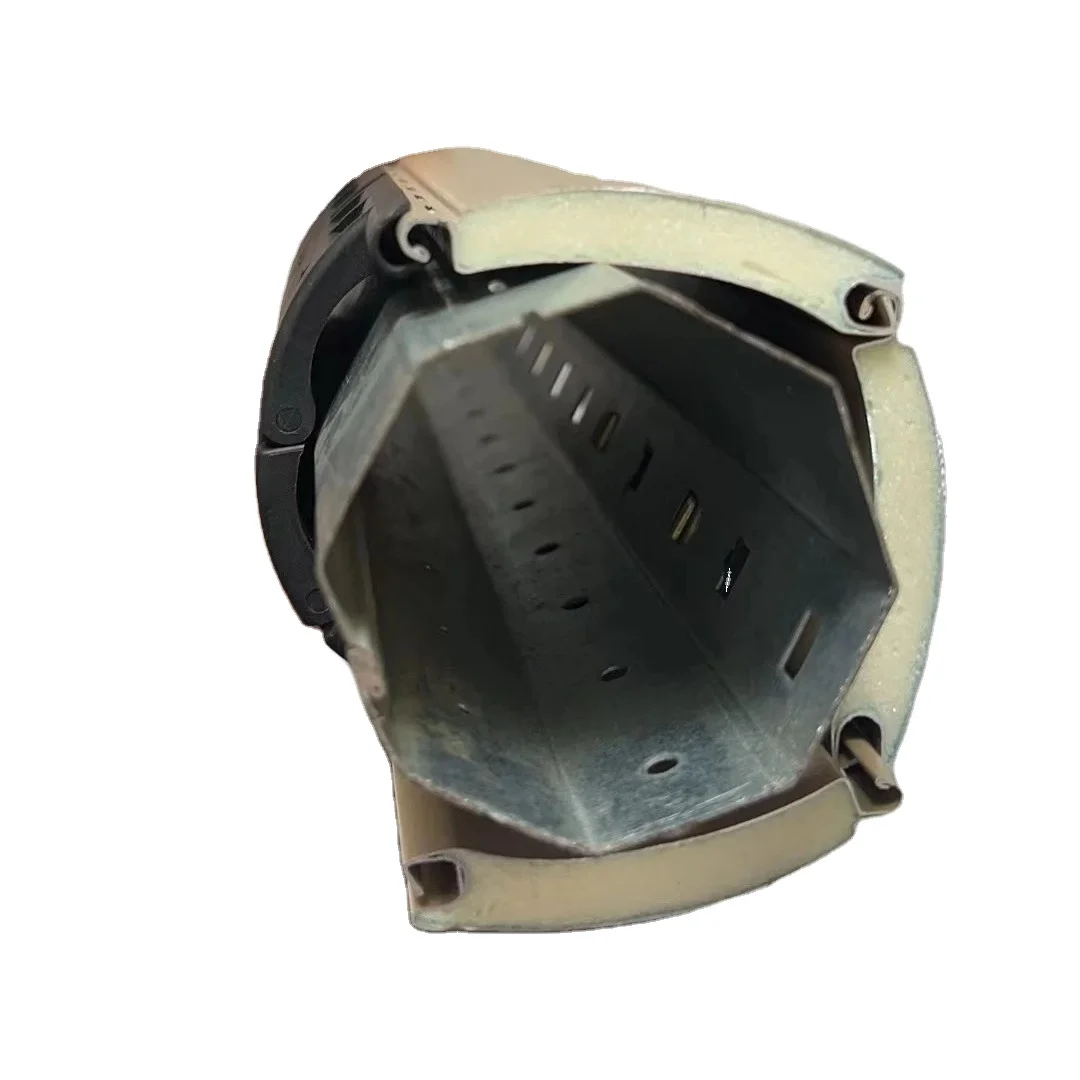

These guide rail roll forming machines are known for their robustness and durability. Constructed with strong, durable materials ensure the ability of longevity and endure for years under repeated use. To obtain a product that meets the required safety demands, these machines include specific features and automatic controls in their designs. Safety is an obvious concern with any manufacturing environment, and this element remains highly important.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY