فوائد خط ماكينة التقطيع

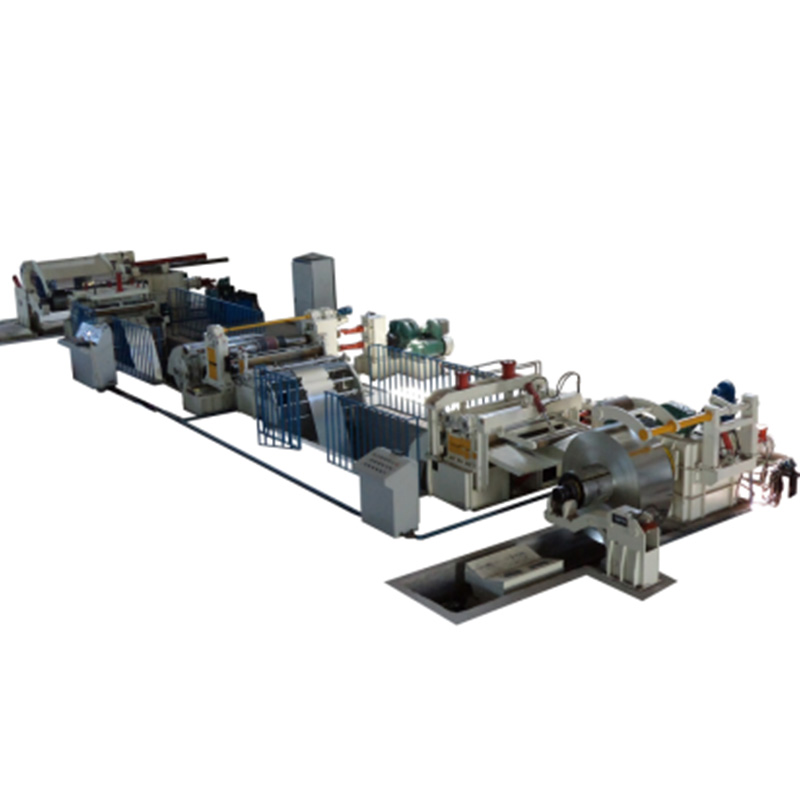

فوائد استخدام ماكينة التقطيع لأداء عملك: الشيء الأول هو أنها يمكن أن توفر لك بعض الوقت. يستغرق الأمر وقتًا لتقطيع الأسطوانات الكبيرة باستخدام شفرة واحدة لأنك تستطيع قطع قطعة واحدة فقط في كل مرة. ومع ذلك، عند استخدام ماكينة التقطيع يمكنك تنفيذ عملية التقطيع لعدة أسطوانات دفعة واحدة! هذا أسرع بكثير ويحافظ على تدفق إنتاج المحتوى.

استخدام آلة التقطيع له فائدة رائعة أخرى أيضًا — يمكن أن يساعدك في توفير المال. إذا كنت تقطع الأسطوانات يدويًا، فقد يحدث هدر أحيانًا. يحدث هذا الهدر لأن القص قد لا يكون مستقيمًا أو موحدًا. ومع ذلك، باستخدام آلة التقطيع، يمكنك إجراء قطع مستقيمة تمامًا في كل مرة! مما يعني وجود هدر أقل في المواد، ويمكنك استخدام المزيد مما لديك.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY