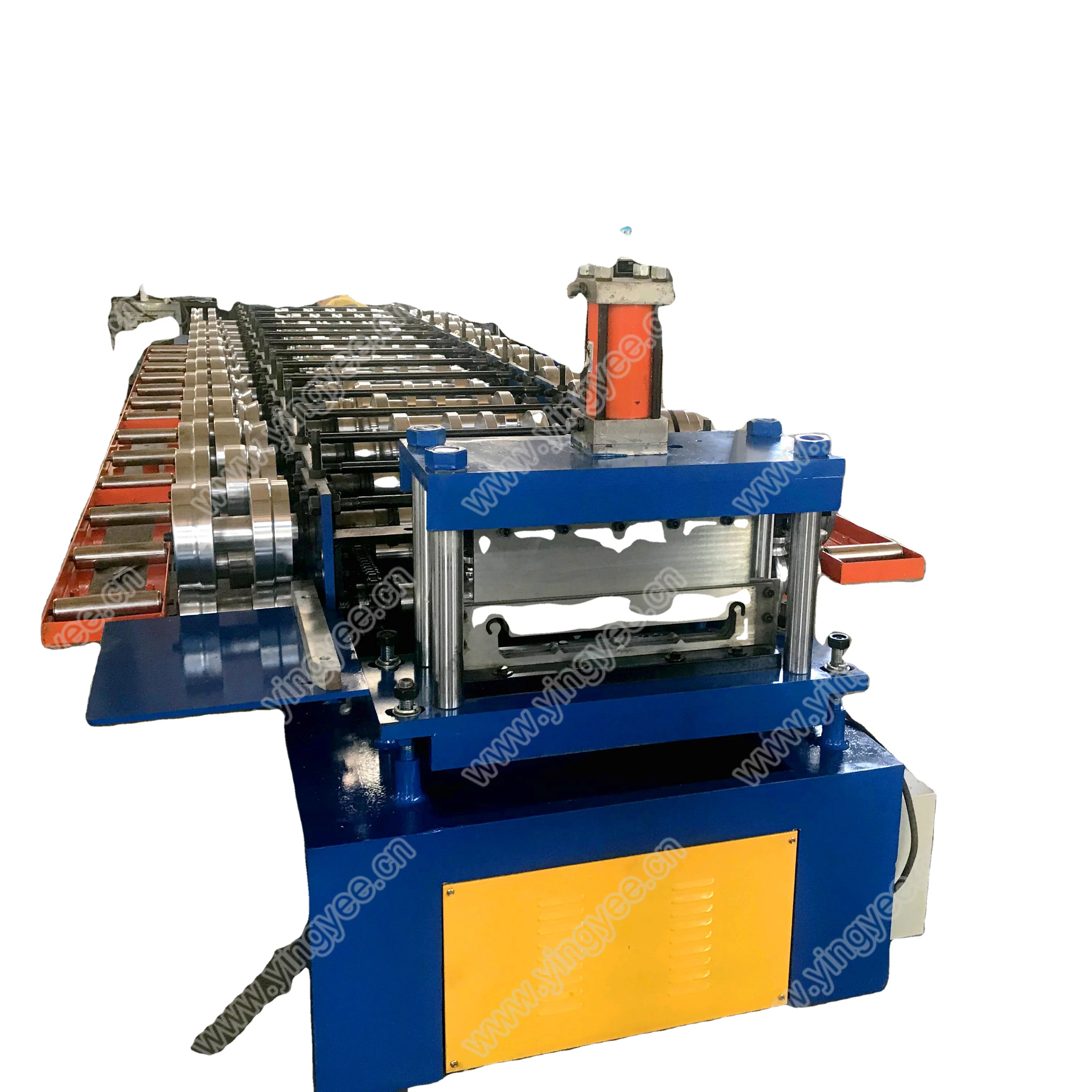

Ayağa dikilmiş Çatı Paneli Kaydırma Makinesi'nin Çeşitli Tasarım Yetenekleri

YINGYEE duruş sebki metal çatı makinesi çok çeşitli türde metal çatı yapabilir, bu da en büyük avantajlarından biridir. Sadece bir stil değil, duran jöle profili gibi daha karmaşık profiller olan trapezoid, snap lock ve double lock gibi profilleri de üretebilir. Bu esneklik, rulman makinesine neredeyse herhangi bir boyutta veya şekildedeki panelleri üretme olanağı sağlar. Çeşitli tasarımlar oluşturmak için kullanılırken, evler, ofisler ve diğer binaların yapısıyla uyumlu bir şekilde stilendirilebilir.

ÇATI METAL ÇATILARI ÜRETMEKEVETİNİN GÖREVİKaliteli metal çatılar yapmak konusunda, kalite üzerine odaklanmak son derece önem taşır. Bu, üretilen çatının en iyi kalitede olduğundan emin olur ve YINGYEE'nin standing seam roll former'ı bunu gerçekleştirmeye yardımcı olur. Rulo makinaları, performans için gerekli olan temel malzemeler gibi kalın çelikten yapılmıştır. Ayrıca, kesme mekanizması oldukça hassas olup, her panelin doğru kalınlık ve güçte üretilmesini sağlar. Kaliteye vurgu yaparak, tamamlanan çatıların güvenilir ve hava koşullarına karşı dayanıklı olacağından emin olunmasını sağlar.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY