All

-

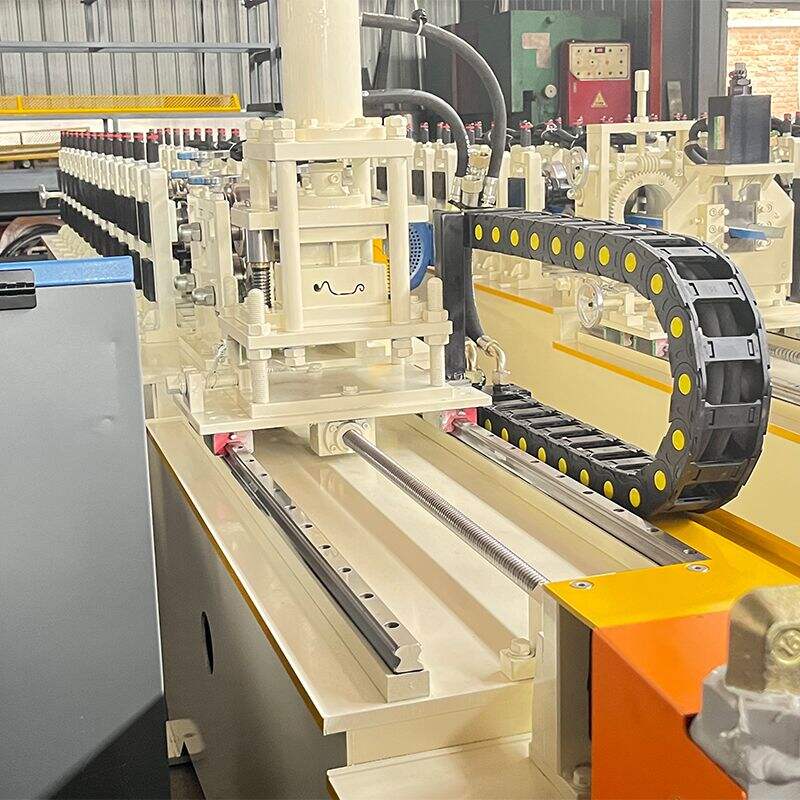

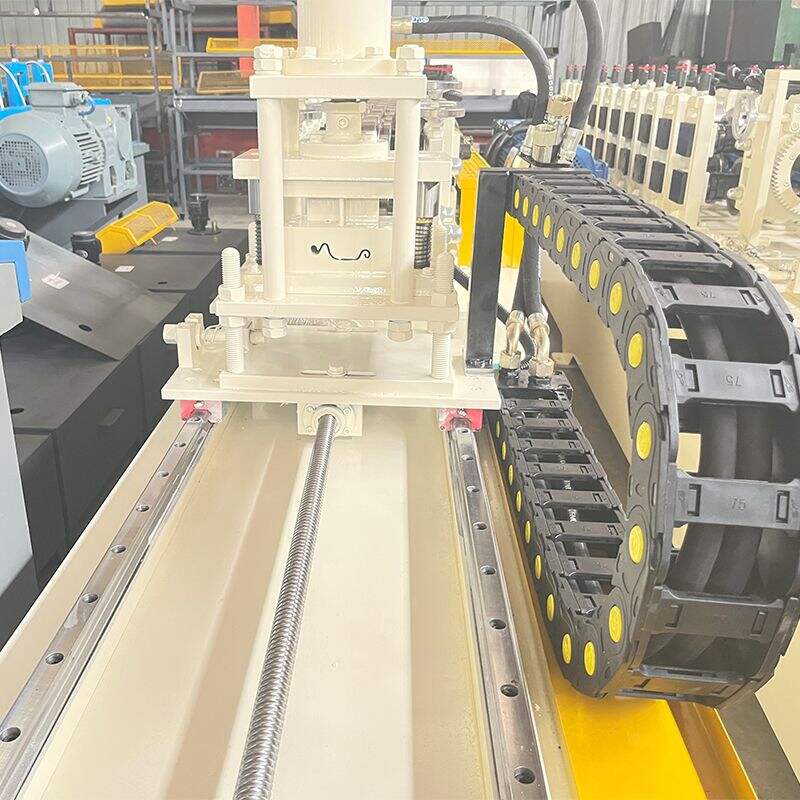

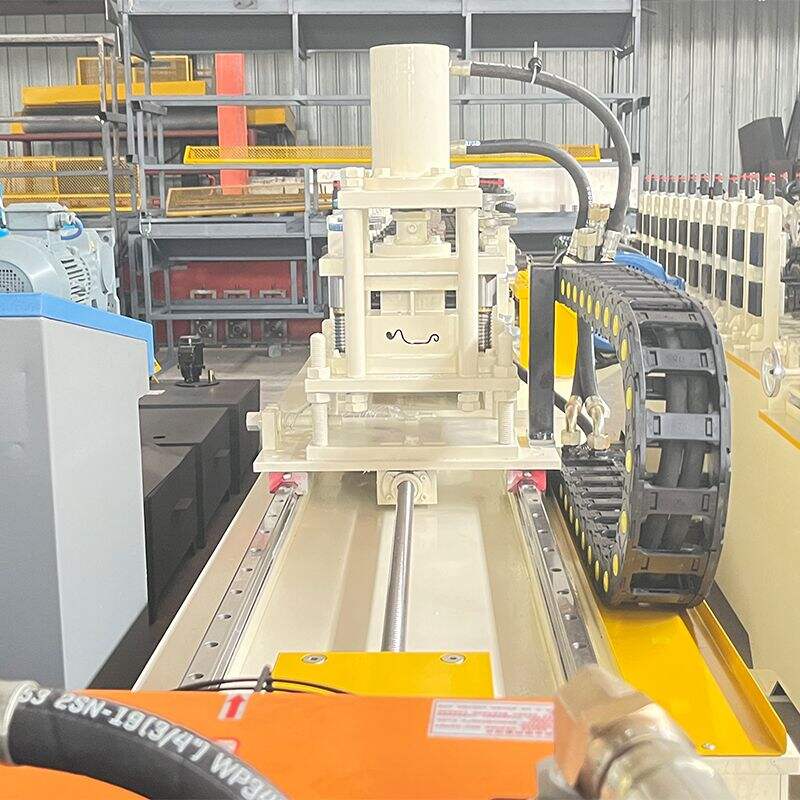

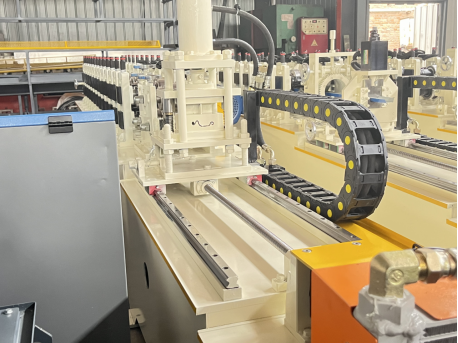

Roof sheet roll forming machine

- IBR roof sheet roll forming machine

- Corrugated roof sheet roll forming machine

- Glazed tile roof sheet roll forming machine

- Double layer roof sheet roll forming machine

- Floor deck roll forming machine

- Ridge cap roll forming machine

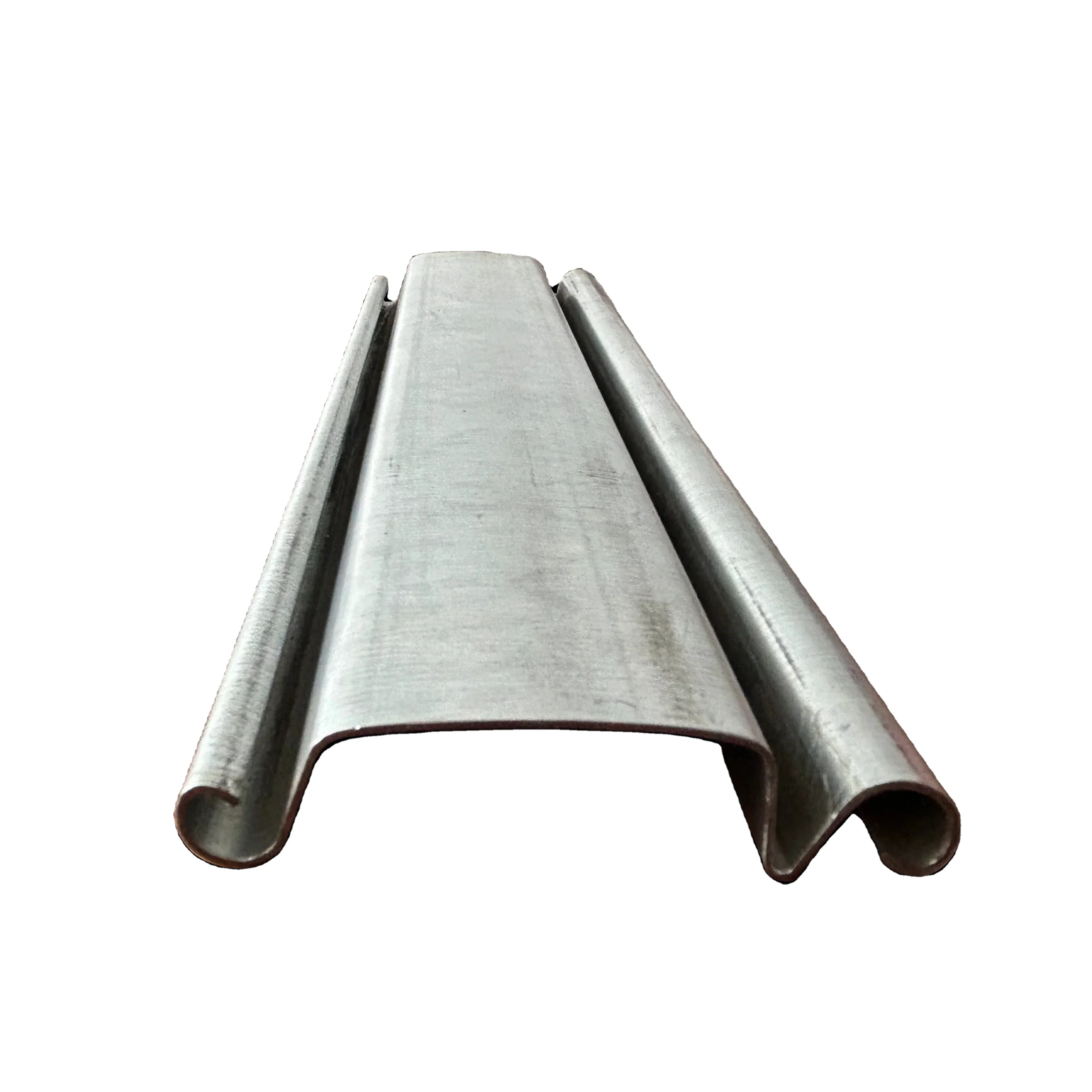

- Seam lock roll forming machine

- Standing seam panels roll forming machine

- Big span roll forming machine

- Curving machine

- Sandwich panel roll forming machine

-

Purlin roll forming machine

-

Drywall and ceiling system roll forming machine

- Main channel roll forming machine

- Furring channel roll forming machine

- Wall angle roll forming machine

- Omega roll forming machine

- Stud and track roll forming machine

- Double-out profiles roll forming machine

- Tee ceiling production line

- Edge bead roll forming machine

- Suspended ceiling roll forming machine

- Fut ceiling roll forming machine

- Groove ceiling roll forming machine

- Grille ceiling roll forming machine

- Aluminum Buckle Plate production line

-

Electrical cabinet production line

- Electrical junction cabinet roll forming machine

- Front door/back panel/mounting panel making machine

- Rain hat of electric cabinet roll forming machine

- Electrical rail roll forming machine

- Cable tray roll forming machine

- BSW metal switch boxes production line

- ANSI metal switch boxes production line

- Electrical cabinet frame roll forming machine

-

Roller shutter door roll forming machine

-

Storage system production line

-

Downpipe system roll forming machine

-

Thread rolling machine

-

Straighten and cutting machine

-

Slitting line

-

Cut to length line

-

Tube mill line

-

NC shearing machine

-

Press break machine

-

Solar bracket roll forming machine

-

Automatic packing system

-

3D laser cutting machine

-

Punching machine

-

Decoiler

-

Steel coil

-

Welded mesh machine

EN

EN