If you have ever seen a house under construction, you know a roof is important. Roofs are a protective shield for our homes. It protects us from the wind, rain, and sunlight. But have you ever thought about how they are made? Did you know companies such as YINGYEE make roofs with specialized machines called roofing sheet roll forming machine? These devices are essential components in the roof manufacturing process.

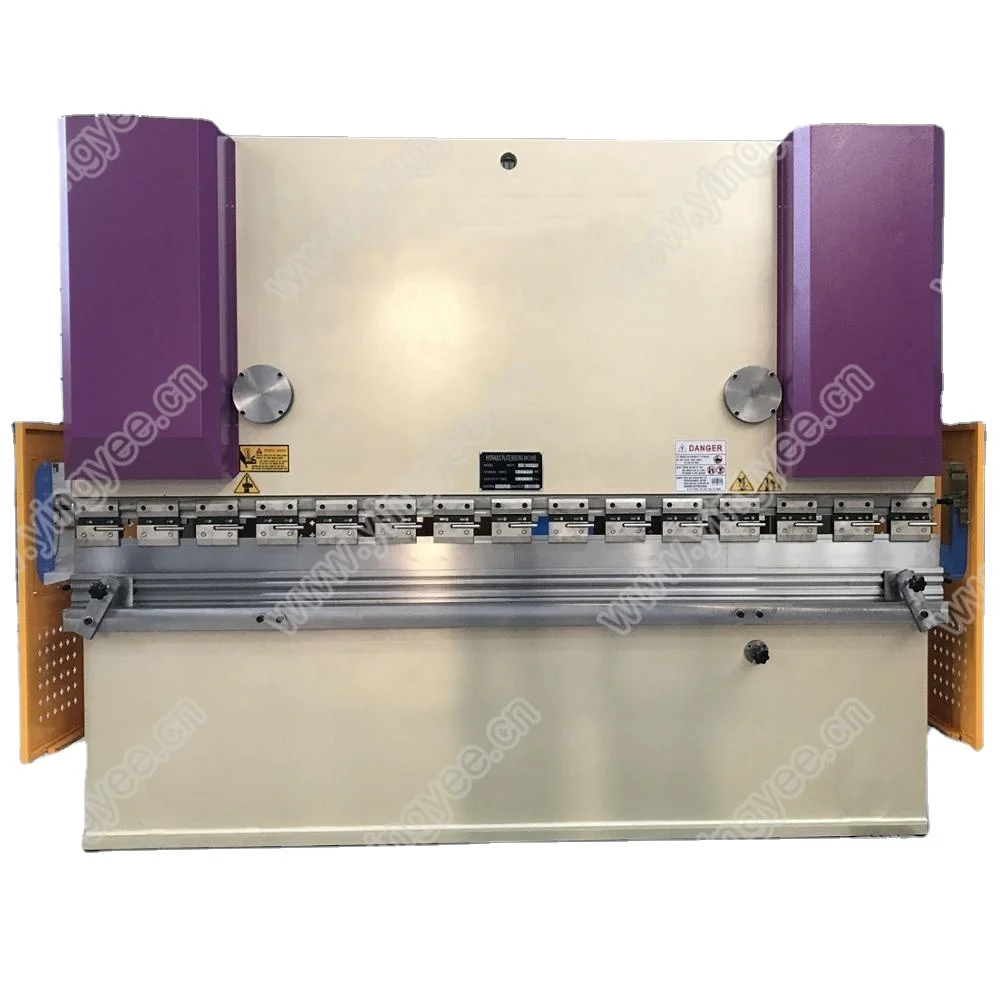

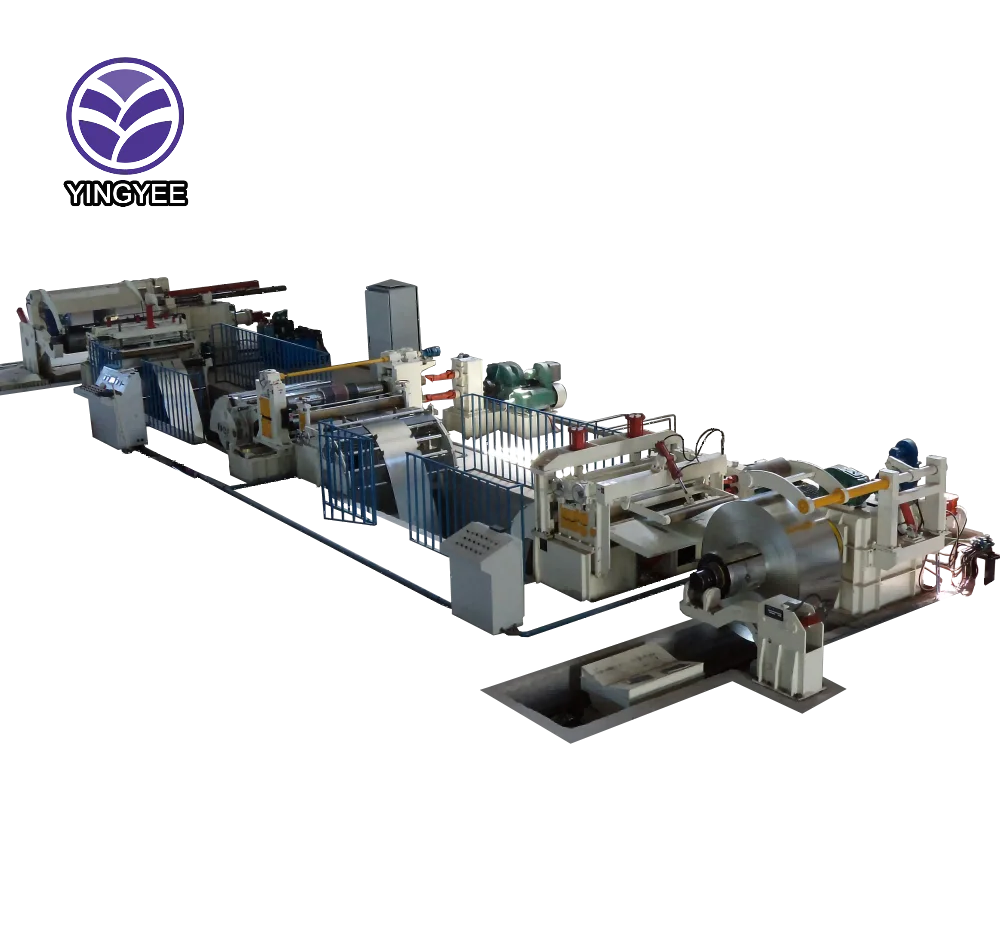

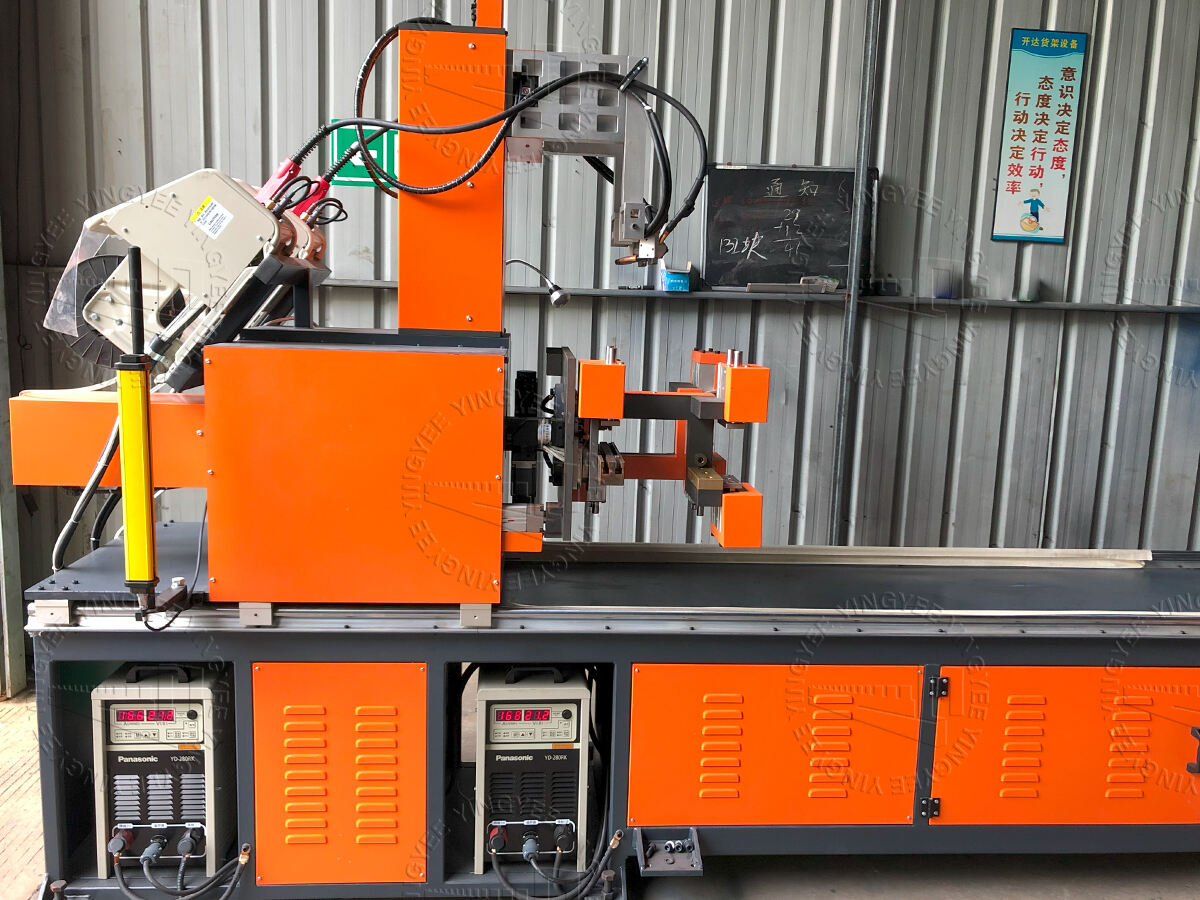

What Are Roofing Sheet Rolling Machines?Roofing sheet rolling machines are really useful for manufacturers who produce roofing materials, specifically metal-based sheets. These machines are built to produce different sizes and shapes of sheets. For instance, they can create sheets that are long or short, flat or curved, based on what someone wants for their roof. You start with a long piece of metal for stock. The metal is put into the machine which has special rollers inside. This is where the metal passes through those rollers and becomes formed into the design it needs to be. Due to the machines known as roofing sheet rolling machines, YINGYEE and similar companies can produce roofs far quicker and easier than can be manually manufactured, which could prove extremely time-consuming and with considerable effort.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY