Factors that impact the price of slitting lines

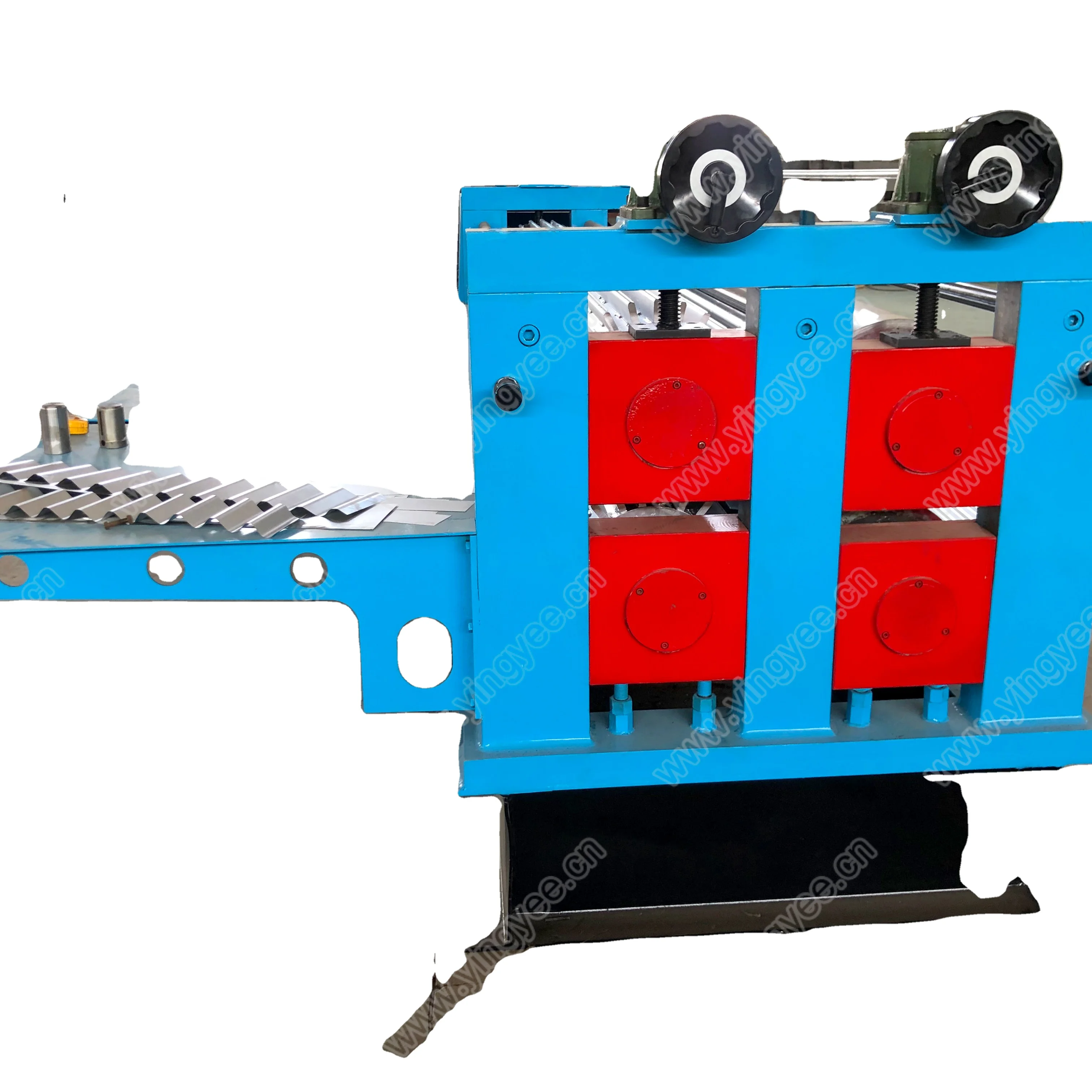

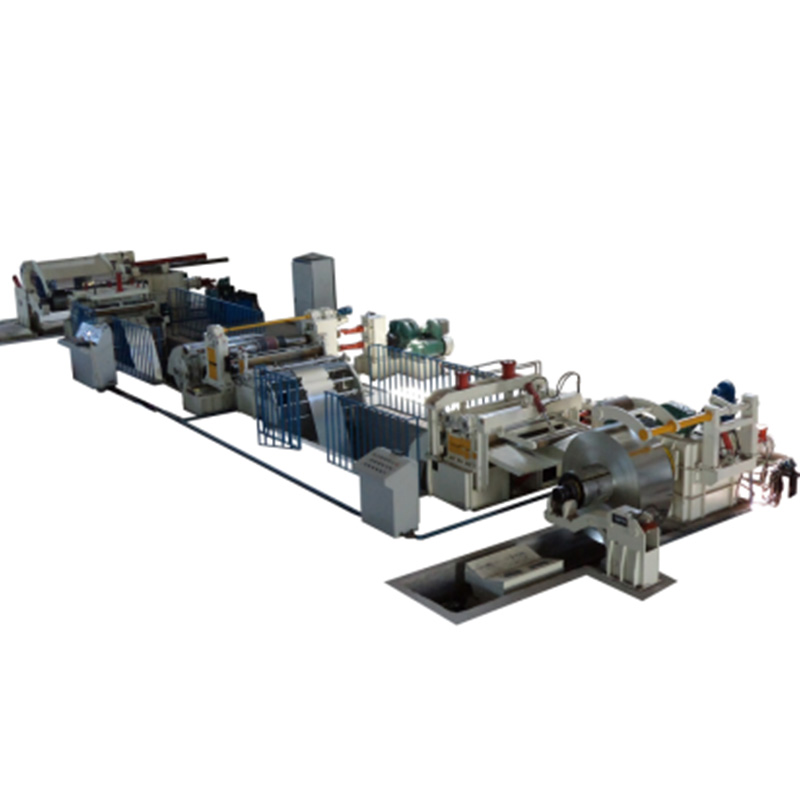

Material you are cutting Material being cut also changes the cost. The overall price can fluctuate depending upon whether metal was steel, aluminum or something else because different metals have need of differing sorts; machines and blades. For example, you will need to use higher quality blades if -as in our case- are cutting harder metals. The material of the blades and how it is put together matter too. The construction and the quality of components Also matters for its long lasting functioning capability which can be taken care in this price range.

Slitting line is a big investment, so it will be wise for you to consider less expensive way too. If you are on a budget, one option is to purchase an old or second-hand box-making machine. This will help you to save money, but please be aware that in some cases this could mean extra cash out for repairs and maintenance. On the Buying side, you absolutely need to inspect any used machine before purchase.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY