These are very important machines in garment making. They help produce thread to sew fabric together. Thread machines have evolved over many years. Let’s find out how these machines work and how they allowed us to make clothes faster and better.

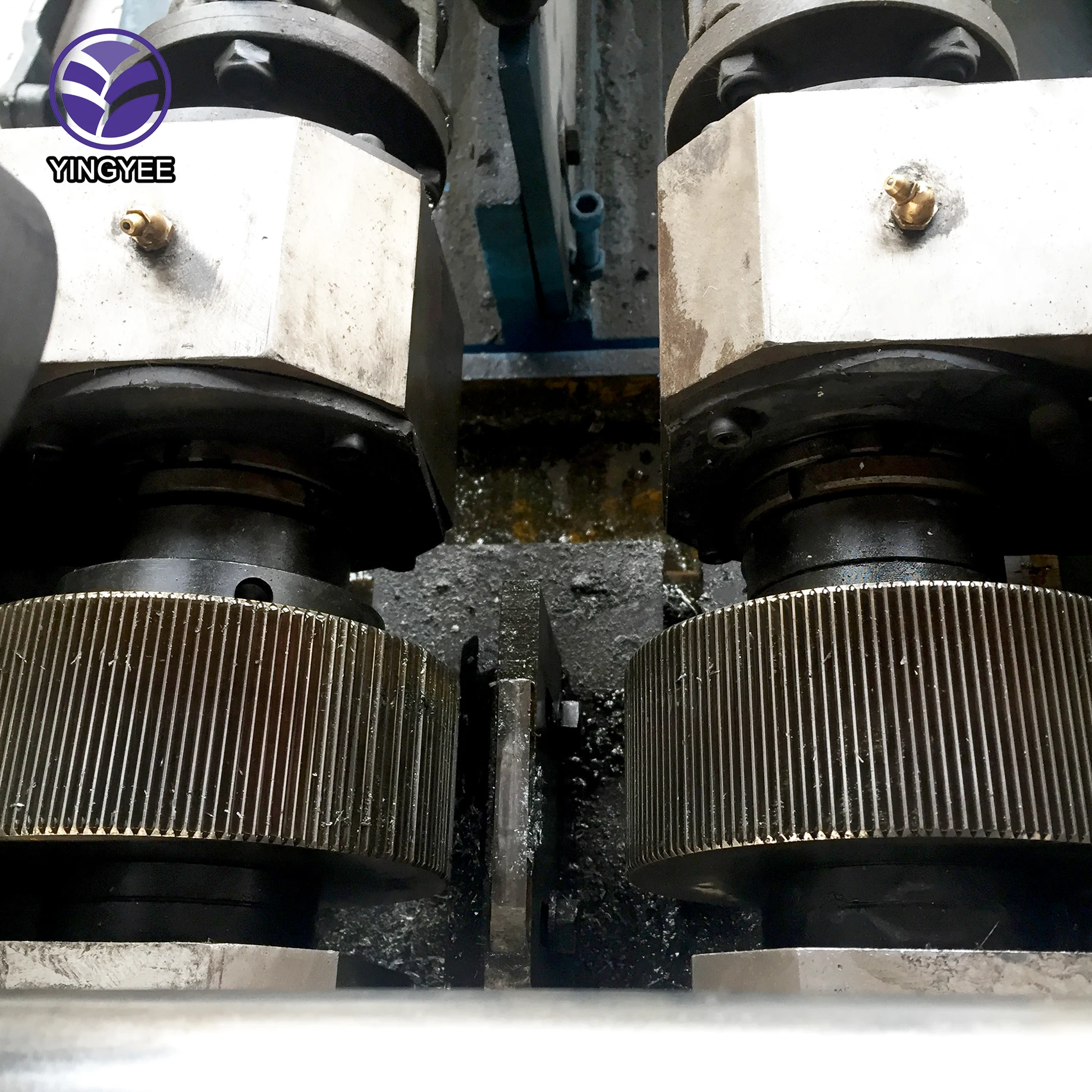

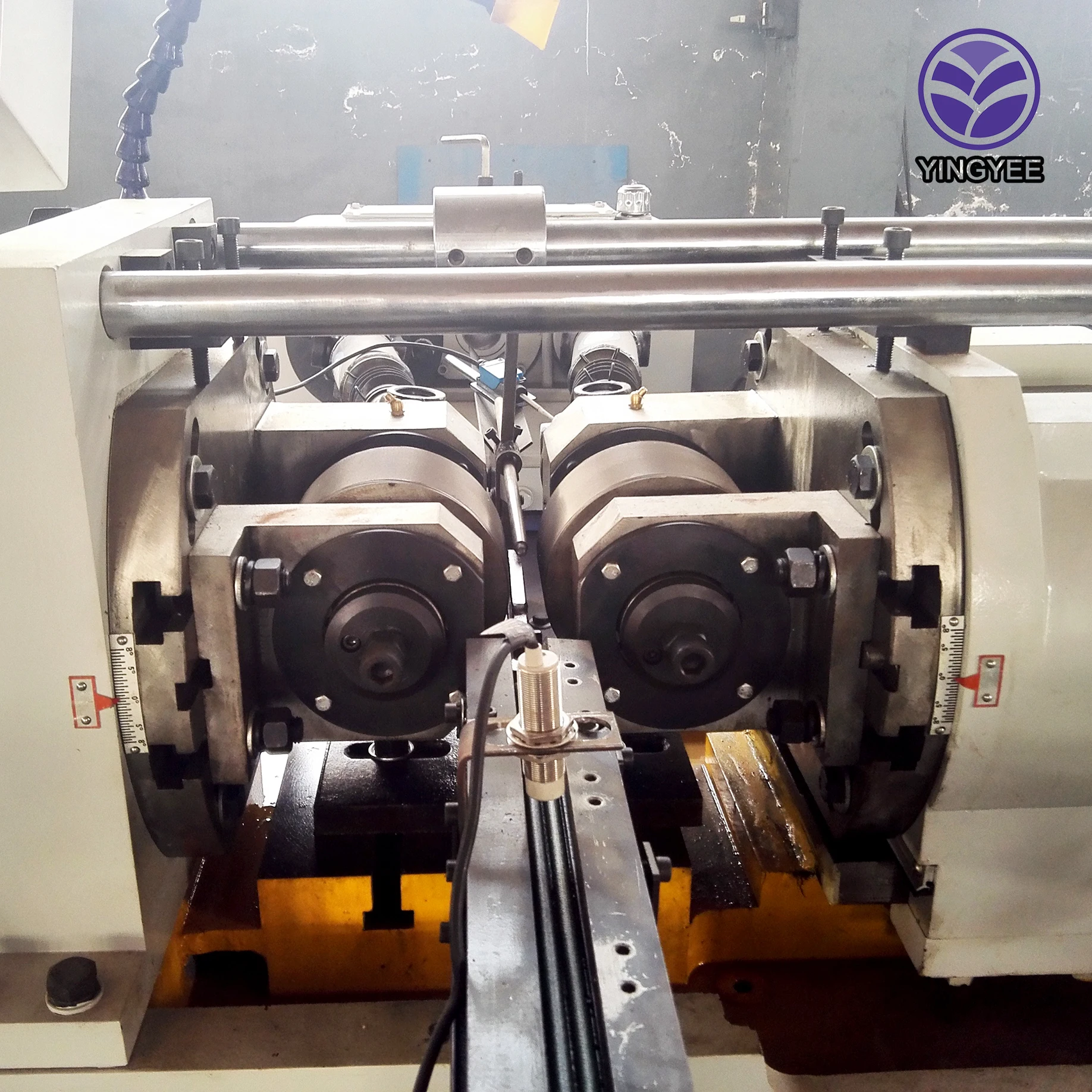

Many, many years ago people had to make thread by hand. It was a slow, painful process.” Then came the 18th century, and the invention of Special-Shape Welding Machine. The machines could produce thread much more quickly than people could produce it by hand. Thread machines have been developed and improved with time. Today, we are fortunate to have machines such as those produced by YINGYEE that can thread so fast and efficiently.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY