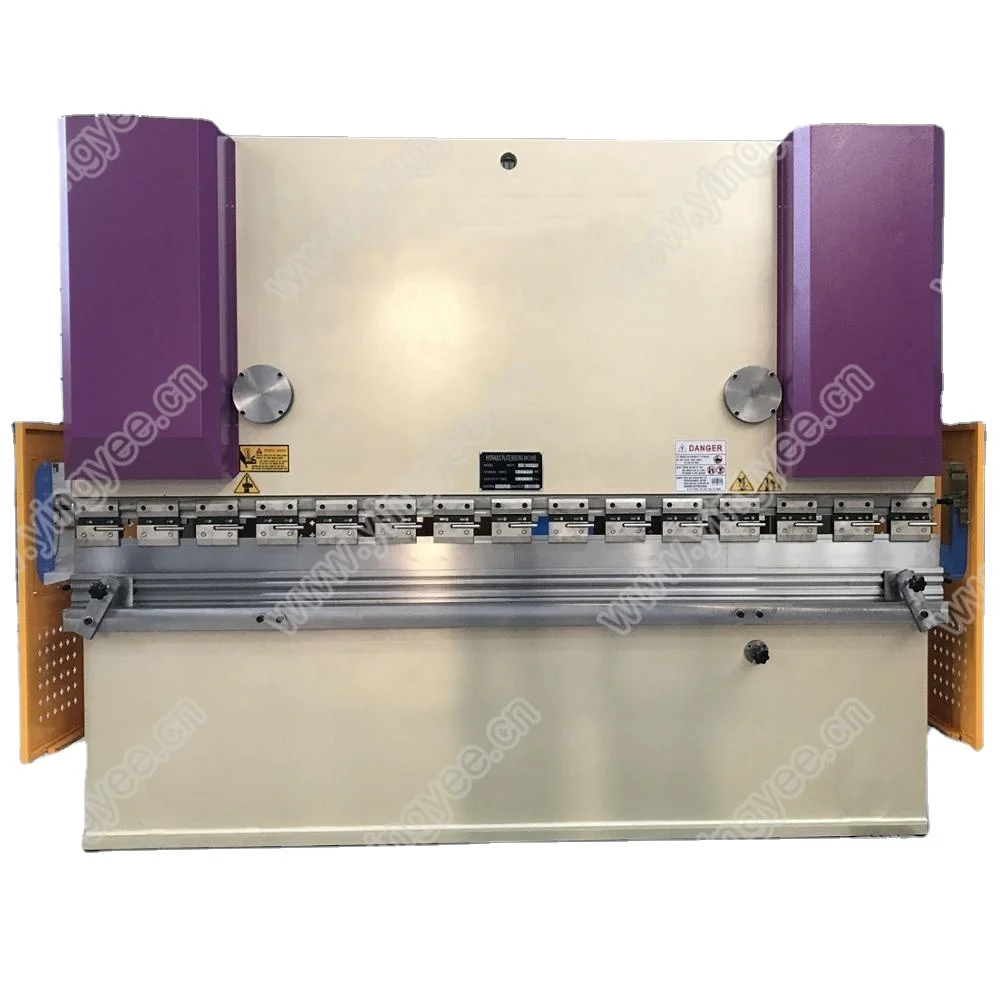

If you were an expert in construction, then I am damn sure that the name drywall roll forming machine will not be a new thing for you. Sounds like a significant and complex tool, but it is actually a special machine that will help you in your work. Here's how it works, and why this can be so useful for you.

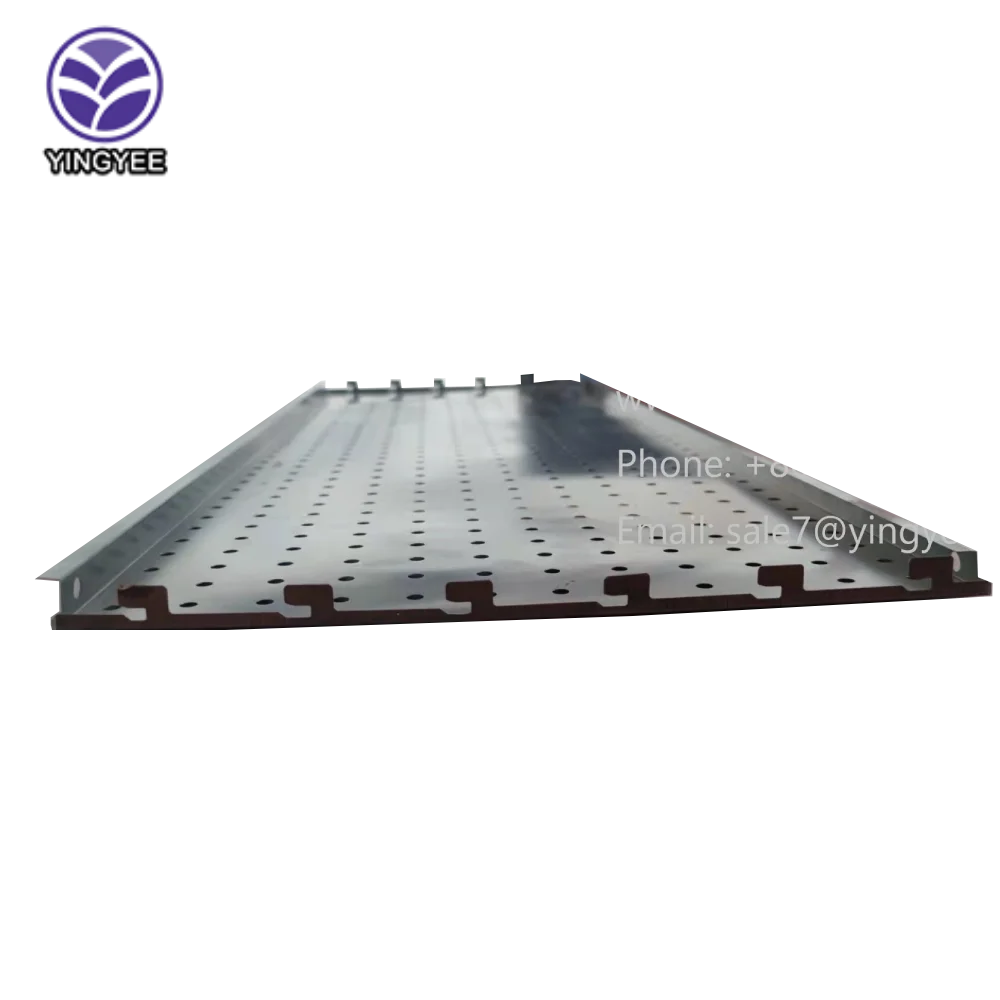

A drywall roll forming machine is a special equipment to place long strips of drywall into numerous shapes. Generally, if you wanted to fashion outlines out of drywall sheets it would be a hard process. It can be time consuming and frustrating to do it all. And when it is put into the drywall roll forming machine, indeed your type desired shape will be produced. This will save you countless time and effort, particularly if your projects involve a lot of shapes to create.

EN

EN

AR

AR BG

BG DA

DA NL

NL FR

FR DE

DE EL

EL IT

IT KO

KO PT

PT RO

RO RU

RU ES

ES TL

TL ID

ID SR

SR SL

SL UK

UK VI

VI GL

GL HU

HU TR

TR FA

FA MS

MS GA

GA CY

CY MK

MK AZ

AZ KA

KA BN

BN BS

BS LA

LA MN

MN NE

NE MY

MY KK

KK UZ

UZ KY

KY